FormLabs’ brand spankers new Form 1+ – more robust mechanics, new resin options and a longer warranty (serviced in Europe)

When FormLabs launched its Form1 3D printer on Kickstarter back in 2012, it took the crowd-funding game by storm. While its goal was $100k, the company eventually closed out its funding campaign with just shy of $3,000,000. While the massive overfunding goal got the headlines, for those of us in the professional industry, FormLabs is interesting for an entirely different reason.

While the bulk of the action up to this point in the desktop 3D printing device market had focussed on filament-based systems (MakerBot, Ultimaker et al.), the Form 1 machine took on stereolithography. It provided higher resolution prints than anything else in its price range ($3299), built effectively in terms of speed and offered a massive reduction in the cost of bringing this type of 3D printing into the design office.

While stereolithography (as a 3D printing method) was invented and arguably dominated by 3D Systems, it’s not the only player in the game – but none of those organisations offered this type of technology at the sub $5,000 price range.

In the intervening 20 months, the company has shipped the machines its backers ordered and begun a more traditional sales routine. We’ve seen these popping up in all manner of places. Design offices in London, museums in New York and all places in between.

Between then and now

It has also been busy working in several areas. Firstly, the software side of things has progressed nicely. While most 3D printers require support of your models in some form or another, when you’re building using UV curable resin upside down (the Form1, like several others, draws upwards, using capillary action to distribute the resin for each layer), then the support structure is key – mostly so the bloody thing doesn’t fall off into a pool of uncured resins.

Another is in the materials and resins area. The Form1 came to market with a single material, a nice grey resin, but this has been expanded out to include a clear and a white option. There’s more on this later on.

The end result is a machine that will build you a tidy, high resolution model (up to 125 x 125 x 165mm) in 25 micron (variable) layers, comes in a small, desktop suitable, package, is provided with a finishing kit and works out of the box – all for under 3,000 quid. It’s been on the market for a while and folks are adopting it, particularly amongst those early adopters and enthusiasts.

So what are they announcing today?

The answer is that the team has been learning from its experiences over the last couple of years and is launching the Form1+. Anyone that’s had a mooch around the support forums will know that early units have had issues (as any product would) and some of those adopters that were (rather unrealistically) expecting a machine that works out of the box without any tinkering, seemed disappointed. As a counter point to that, it’s also been clear that the FormLabs support team has been pretty proactive in their engagement with this set of early adopters.

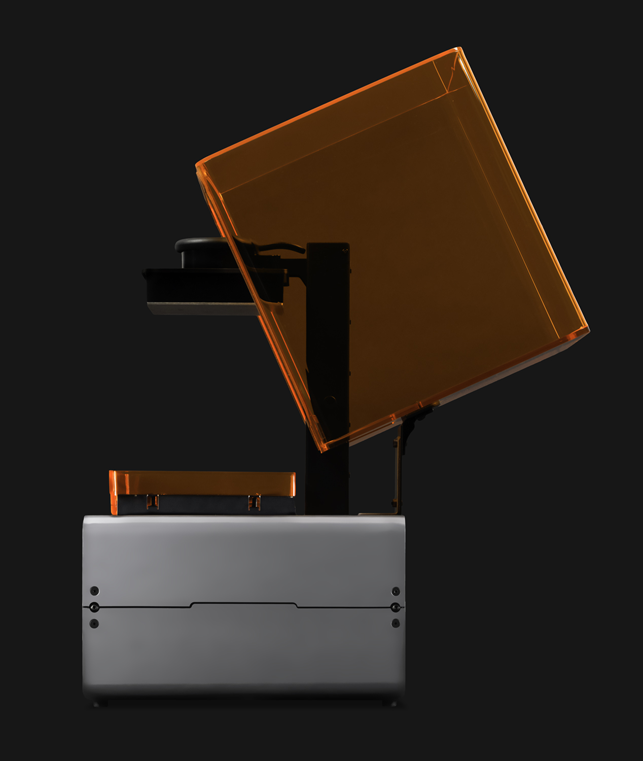

As the name implies, the Form1+ features the same build capacity as the original unit. Visually, the product looks the same with a few changes here and there. But the really important stuff is under the hood.

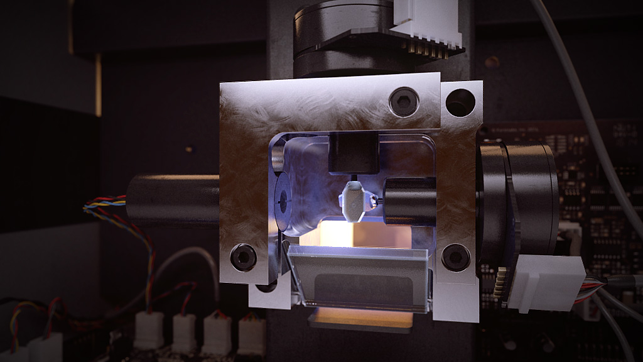

For those that aren’t familiar with how the machine works, the laser and optics are in the base of the unit. These pass the UV spot beam through a clear resin tray (with a coat of silicone) to cure a layer of resin on the base of the build platform. This resin layer is formed on the build platform, essentially, dipping into that tray full of resin to the required layer thickness.

Once that layer is cured, the platform raises up, peels away from the silicone layer and capillary action replaces the resin layer to the required thickness. Then the process repeats and the parts form, upside down, suspended from the build platform.

While it’s not a process unique to FormLabs (envisiontec’s Perfactory machines work in a similar manner, as do several others) all such machines share similar problems. If any part of the process doesn’t work correctly, the build will fail, fall off or general make a bit of a mess. And it’s these issues that the Form1+ looks to address.

The laser optics and galvanometer have been upgraded. This should allow the system to build more quickly (the laser is more powerful, so should cure the resin more quickly and the galvo should let the laser trace each layer more speedily). Speed improvements are asserted to be 40% and claimed to bring the system in line with lower resolution filament machines.

The Form 1+’s new galvo mechanism – more resilient and quickly build speeds

There’s also been a redesign of the resin tray. This is one of those factors that many hadn’t considered; that the resins trays needed to be replaced. These store the resin as the parts are building, have a layer of silicone on the base, but also need to be optically clear so the laser can pass through and cure the resin between that silicone layer and the build platform.

A shiny new resin tray is injection moulded in orange plastic, meaning resin is less likely to cure in the vat during and post build

The build platforms themselves could also degrade with heavy use. Both units aren’t inconsiderable in their cost, weighing in at $99 for the build platform and $69 for the resin tray.

Again, for the Form 1+, the resin trays have been redesigned. They’re now an injection moulded single piece component and are now orange. This means that any unwanted curing by light leak is reduced – and hopefully, partially cured resin won’t need so much after care to clean out.

Finally, under the hood, the peel mechanism has been redesigned to be more reliable – thought details are scant at present.

If you fancy a look at what the team has been up to, here’s the video, complete with slow dolly and track moves, down tempo soundtrack and some nice animation work.

//player.vimeo.com/video/97770946

Introducing the Form 1+ from Formlabs on Vimeo.

Localised service and repair

Alongside the updates inherent in the new machine, the Form1+ launch also sees another factor considered by the FormLabs team – what happens when something goes wrong or awry.

While the desktop 3D printing market has burgeoned due to the interest outside of the professional market, the tinkerers and the makers, it’s also hidden one of the issues that face the professional looking for a reliable system to bring in house. The pro doesn’t have time to spend stripping down a 3D printer to get it running again – it needs to be a tool that’s reliable, but also one that can be repaired quickly and efficiently. These machines (as with any machine) can go wrong. The important part is being able to get them fixed and fixed in a time critical manner.

FormLabs’ machine was delivery factory calibrated, but the users ability to repair or maintain that machine was limited. This typically meant that the whole machine needed to be returned to base – and for those of us this side of the pond, sending a 3D printer back to its US headquarters in Boston simple wasn’t an option.

Recognising this and looking to service a large market, FormLabs has established a European service – in the UK. That means that shipping as well as service should be a much more efficient affair over all.

It’s also worth noting that from now on, the company will be offering a 1-year warranty of all Form 1+s – which brings it in line customers expectations at the higher-end of the desktop market.

The last update that’s coming out of this release is that the company is expanding its materials options to now also include a black coloured resin to complement the white, grey and clear.

Of course, if you’ve already invested in the original Form 1, the company will also be launching an upgrade program in the near future.

From the horse’s mouth

To learn a little more, we asked a few questions in advance of the launch.

Al Dean: You’re bringing service, maintenance and repair to the UK to cover the European market. Our research tells us this is a key factor for many in the professional market – could you give us a few thoughts on why you felt this was important for growth of the company and its position in the market?

Gideon Balloch, Formlabs operations: When we think of our customers we know that they are looking for more than great print results – they are looking at the whole experience. This is something we always strive to improve, and our European presence is going to help us step up our game in several measurable ways.

First, we will be able to provide better, faster and more affordable support for our European customers if service is required on their machines. Second, we will be able to deliver products faster and more reliably, while cutting out any need for customers within the European Union to deal with customs.

It’s this attention to detail to the entire user experience that we feel differentiates Formlabs, making improvements like these a major driver of growth. Now when prospective European customers consider the Form 1+, they will be able to trust that they are going to get the reliable, high-quality experience that they deserve.

Al Dean: Perhaps you could give us a few thoughts on what made the UK attractive as a choice for basing these operations?

Gideon Balloch, Formlabs operations: The UK is geographically a great base for our European presence for many reasons, but more than any particulars about the country as a whole we felt it was the characteristics of our new partners Express Group that made this move so attractive. Their 25 years experience in 2D printer repair makes us confident that this partnership will provide the level of service our customers expect, and their broader European presence is going to be essential in helping us drive growth. We’re thrilled to be working with them and excited for the future that the partnership makes possible.

Al Dean: Let’s talk materials. Your current materials line up is nicely rounded. That said, there’s a huge range of third party SL materials, whether different purpose resins, whether filled materials (I’m thinking not only the maker level suppliers (like MakerJuice), but also the older guard like DSM Somos. Any plans to support use and experimentation with a wider range of materials?

Sam Jacoby, marketing director, FormLabs:We know that a lot of our customers have been experimenting with different resins — and while it’s certainly exciting to find new applications for our machine, we’re focused on creating the best complete, end-to-end experience possible. That’s why we have our materials science team that develops materials for exclusive use with the Form 1+.

Al Dean: On the subject of MakerJuice, I see that they’re selling a Form1 compatible resin tray – any thoughts? Something that you would discourage or encourage?

Sam Jacoby, marketing director, FormLabs: A lot goes into making an affordable, professional quality machine, and the resin tank is no exception. We’ve put an enormous amount of work into the new Form 1+ resin tank — it’s now made of injection-moulded orange acrylic, so in addition to blocking extraneous light, it’s much more durable.

Al Dean: Any plans to broaden out your offering in terms of finishing solutions – the Form1 comes with the finishing station, but we’re hearing stories of users buying in UV curing ovens – any plans on that front?

Sam Jacoby, marketing director, FormLabs: We’re always looking at ways to make the printing experience easier and smoother. Some people have been experimenting with various curing ovens – but at the moment, we’re really focused on making the print experience as good as possible.

Few thoughts

FormLabs and its initial machine changed a great deal in the 3D printing world. The product looked less like an A-level design product and more like an appliance – something that is becoming more and more common (and something I’ve discussed before).

What’s interesting with the launch of the Form 1+ is seeing how the company is maturing from its MIT roots, learning from issues that early adopters have encountered over the last 20 months and perhaps also learning what’s stopping wider adoption in other markets.

The new machine iterates the initial product, and introduces some key upgrades that make it more efficient and more reliable – two of the key factors for the professional. But perhaps those with an interest in bringing this type of technology in house and doing so into offices or workshops that are the wrong side of the Atlantic, the big news for this release has to be FormLabs introducing service, repair and of course, sales to Europe. That makes things much more interesting for all of us.

For me, the stereolithography machine market is the one to watch this year and next. FormLabs clearly has plans for expansion, Autodesk is getting some skin in the game with its own machine coming later this year and there’s a whole host of other SL machines coming to market at the same time.

What’s also interesting is how the older guard is reacting. If you look at 3D Systems’ ProJet 1200, it’s a reaction against this surge of interest in a fundamental 3D printing technology into its traditional market stronghold and a good one at that.

But on the subject of the FormLabs announcement today, it’s a solid improvement – not only in the machine (remember, this is less that two years old) but also in the business support that surrounds it. With more local (over here) support, service and sales (the latter of which is key when you’re looking at peripherals and consumables) and a considerably longer warranty periods for the new product, it should make the Form 1+ attractive to more professional outfits looking for high resolution prints.

FormLabs updates Form 1 3D printer & introduces European servicing

Default