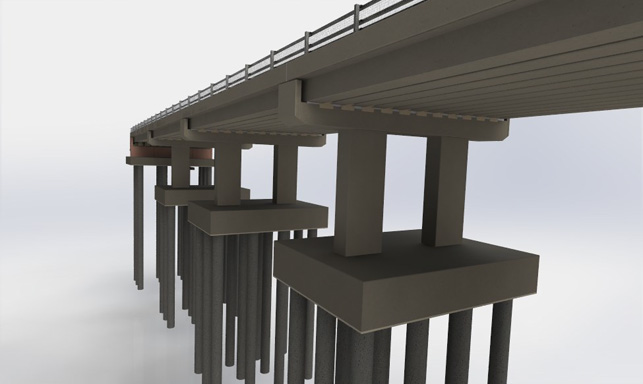

DriveWorks enables the team to automate the development of assemblies and engineering bridge drawings

Through its operations around the world, across the building and infrastructure sectors, Laing O’Rourke aims to secure its position as a recognised leader for innovation and excellence in the construction industry. Recently, the company has collaborated with civil engineering consultancy Tony Gee and Partners and Cambridge University to develop a unified digital delivery process for the bridge industry.

The project configures bridge designs from a set of key inputs and a library of parametric components.

The key focus of the project is to create a common standard by synchronising data and protocols, with the aim of improving interoperability between different parts of the bridge-building process. The project integrates best practices for manufacturing, assembly and design, to ensure consistent data formats and reduce manual processes required between stages.

For this to happen, naming conventions and output files from each stage of the process need to be structured and arranged in a systematic way. Using software from DriveWorks, Laing O’Rourke can specify rules to determine how and where each file is saved. As the lead partner of the research project consortium, the company brought to the project extensive experience in logistics, building designed structures, manufacturing through to site transportation, installation and handover.

We wanted to implement a system that gave users the ability to make informed decisions so they could quickly see the impact of their decisions on the overall design Dr Scott McGovern, Laing O’Rourke

AdvertisementAdvertisement

Tony Gee and Partners, meanwhile, provided valuable insight related to design codes, engineering calculations, materials and design options, while the University of Cambridge team offered technical experience into state-of-the-art methods for design optimisation and data structuring.

Laing O’Rourke – project lift-off

In 2014, government innovation agency Innovate UK announced a £5.6 million funding competition, drawing on the UK’s evolving expertise in BIM. Laing O’Rourke’s collaborative research project received funding support from Innovate UK, a strong catalyst for the group to start developing a set of design configuration tools for bridges.

The project uses standards to simplify bridge processes and reduce the time it takes to complete a bridge. The current design process is complex and typically, a fully detailed design would take around 30 weeks to complete.

By digitising the design process with this project, Laing O’Rourke has identified savings that could see bridge designs produced in days or weeks, rather than the moretypical months or years.

The design configuration tools, created using SolidWorks and DriveWorks, provide a smoother digital process for the design, manufacture and assembly of components, which reduces the time it takes to complete a bridge.

At DriveWorks World 2018, Laing O’Rourke’s digital engineering leader Dr Scott McGovern explained how the project uses DriveWorks.

“We wanted to implement a system that gave users the ability to make informed decisions so they could quickly see the impact of their decisions on the overall design,” he said.

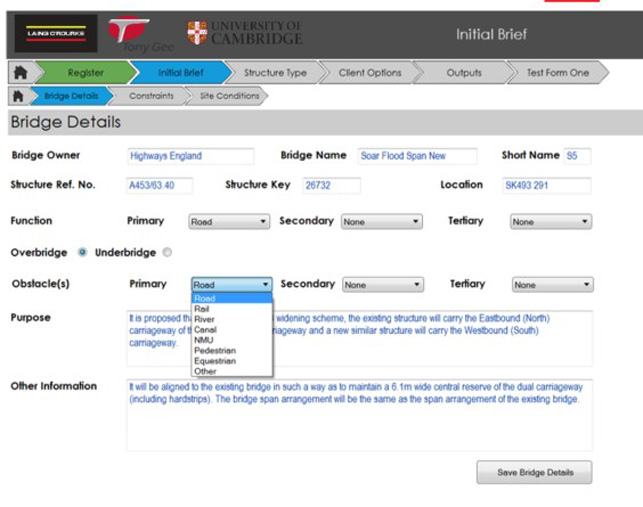

“We’re using DriveWorks in three main areas within our toolset: Firstly, we used the software to build the user interface and capture user defined inputs. We then linked these inputs into our structured dataset that would drive the rules to define component dimensions and features.

Finally, we utilised DriveWorks’ design automation capabilities to automate the development of model assemblies and engineering drawings of the bridge.”

Before and after: a Solidworks render of a bridge, alongside a photo of the bridge following construction

Dramatic time reductions

By using DriveWorks and SolidWorks, McGovern believes that Laing O’Rourke will be able to dramatically reduce the time taken to reach the final design of a bridge.

Bridge design will be simplified with a component-led approach, allowing greater ability for design optimisation of the individual components that make up the kit of parts Dr Scott McGovern, Laing O’Rourke

This has several benefits, he says, as the impact of decisions can be investigated much earlier in the process and reduce the many design iteration cycles that are currently undertaken.

The impact of design on cost, meanwhile, will also be quickly realised, allowing designs to be truly informed by cost, rather than via the traditional process involved in costing up a design.

Construction times are likely to be shortened and component selections will be finalised earlier. It’s hope that this will eliminate the need for last-minute design changes and reduce delivery risk on the project.

“Bridge design will be simplified with a component-led approach, allowing greater ability for design optimisation of the individual components that make up the kit of parts,” McGovern added.

Laing O’Rourke’s extensive experience in designing for manufacturing and digital engineering, he said, allowed the company to take the lead when developing the toolset that was used in the research project. In particular, there are two key constituent parts to this toolset: the data and the software tools.

“We structured the data to provide a reusable set of digital assets, but this alone does not make up the tools,” McGovern said.

“DriveWorks has allowed us to automate the routine processes that we undertake on this data, day in and day out, with traditional bridge design. This automatic creation of models and drawings rapidly improves the turnaround time to reach sign-off on designs and makes all of the downstream benefits possible.”

Laing O’Rourke bridges the data gap with DriveWorks

Default