Simply using recycled materials is not enough to produce packaging that is truly sustainable. What it actually takes is consistent effort to reduce waste and rethink processes, starting right back at the design phase, as sector experts tell Claudia Schergna

If you think you’re not the kind of person who judges a book by its cover, try to focus on what makes you buy a specific bottle of shampoo or can of beer next time you’re at the grocery store.

It’s no secret that customer experience goes way beyond what a certain wine tastes like, the scent of a particular perfume, or how much your cat seems to be enjoying that specific brand of canned food.

The end-to-end experience associated with packaging begins with a customer forced to choose between 10 different brands of very similar products, and ends in a trash bin.

Now more than ever, packaging is way more than just a pretty face. Customers are after sustainable alternatives to plastic. Regulators are imposing more restrictions to limit the use of single-use plastic. Retailers are making bold choices to rethink the way they use and produce packaging.

Trivium Packaging is a US and Europe headquartered company, with 60 locations around the globe, that provides food and cosmetics brands with a sustainable alternative to single-use plastic.

Its aluminium packaging is available in a wide variety of shapes, making it almost as versatile as plastic packaging, with the advantage of being recyclable forever. “Trivium’s metal packaging offers a unique combination of strength, sustainability and print possibilities that creates an exciting canvas for brands,” says the company’s director of R&D and innovation, Nicole Gailey.

Sustainable from day one

As Gailey explains, employing the right kind of material is just one small step in making sure that the production is sustainable: “Trivium partners with its suppliers and understands that the lifecycle of the products begins with them,” she explains.

Sustainable production can be achieved with simple steps, such as monitoring energy consumption and emissions, maximising recycling rates, optimising the use of secondary packaging materials, managing waste appropriately or focusing on limiting water usage.

Trivium teams’ efforts were recognised with a 2021 EcoVadis sustainability platinum rating, the highest on a scale of recognition levels, based upon a company’s sustainability management system.

The development process at Trivium usually starts by listening to consumers’ needs, wishes and pain points, and by coming up with a creative solution for them.

“Once we have the new idea, that’s where the fun really begins,” says Gailey, as she explains the design process.

“As a team, we start moving from ideation to the formal design and scope of the project. Part of this includes the use of various design and simulation software, where initial concepts are developed and shared.”

Sustainable packaging // Zero-waste design process

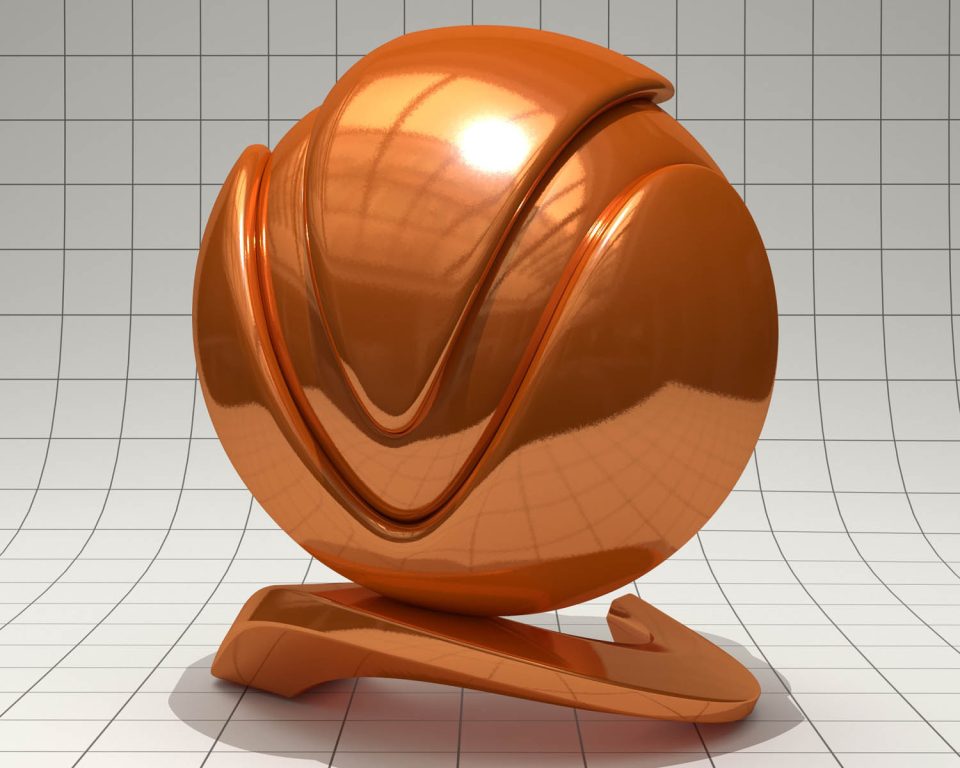

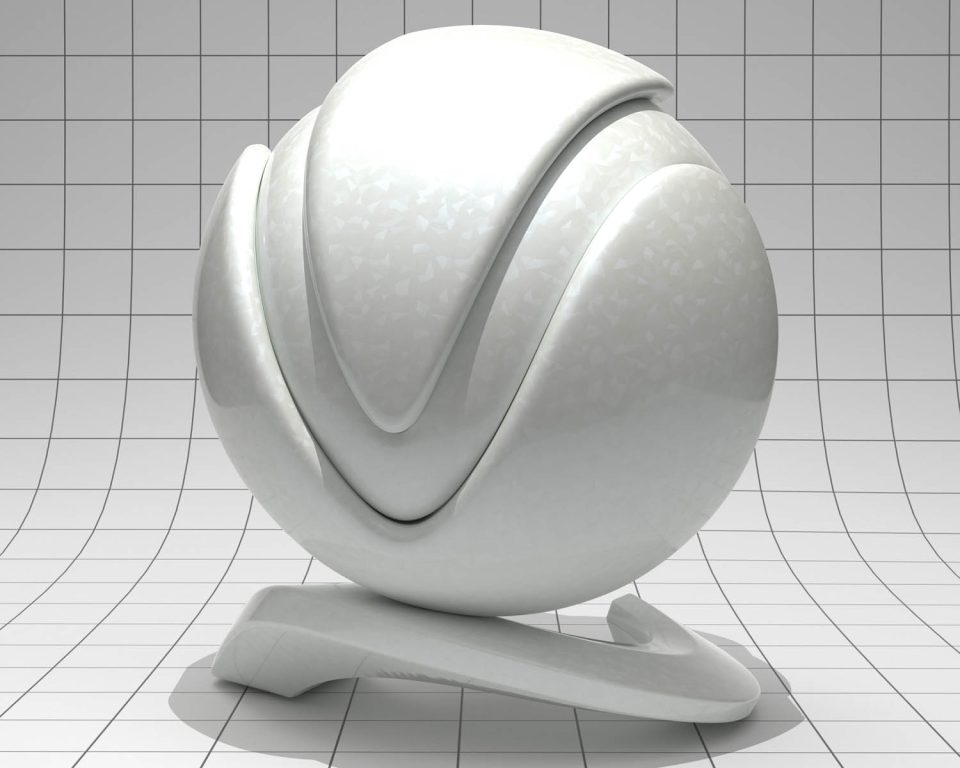

Gailey says 3D printing and rendering software have significantly changed the game at Trivium, as they have broadened the possibilities for the design team in terms of creative freedom and communication.

“This is from a look, form, fit, and even function perspective. For example, we were able to recently use the 3D prototype to print preliminary tooling that was then used to validate the design before moving into the actual manufacturing of the tooling.”

Once testing and evaluation are done, and the team has received acceptance from all stakeholders, the design process moves into the actual realisation of the project.

“Using Solidworks as our key design software, our innovation design engineers develop both 3D models and prints that can then be sent to our internal machine shop for manufacturing,” explains Gailey.

“These 3D models are then also saved and shared with our graphics team for the development of 3D renders for distortion testing, lap line evaluation, and die line preparation for final artwork.”

For the mechanical testing phase, the Trivium design team uses Ansys, which allows it to perform advanced simulations, while Solidworks PDM was selected by the team for managing data. “The various design and simulation software products are a key part of the design process,” explains Gailey. “Not only do they help to ensure that we can successfully execute the project, but they help to minimise risks, costs and time.”

3D printing is also key to the design process, and it’s used in two different ways, says Gailey: “The first thing that it is used for is concept development and confirmation of fitment for new pumps and caps. The customer typically likes to see the concept in a physical way, where they can hold it in their hands. If we didn’t use this, the turnaround time and investment would be significant.”

The second, Gailey adds, is that often the 3D prototypes are used for initial lab testing of new innovative tool designs. This can be for full tools or just components, to understand fitment or even potential preliminary testing.

From physical to digital

Being able to visualise the design and share it with customers before going into the prototyping phase makes the whole workflow even more sustainable, as it saves massive quantities of material and allows designers to share the project digitally worldwide, instead of having to present prototypes to clients.

Despite the wide range of software available on the market, however, visualising a design in its true appearance is not always a piece of cake.

The Warrington, UK-based stamping foil company Foilco, which supplies hot stamping foil to packaging businesses, had been looking for a solution to visualise its offer for years. But photographing the reflective, transparent, holographic foil that the company produces seemed impossible.

“When Jamie, our marketing director, started thinking about digitalising our foil collection, I answered, ‘I’ve been doing this job for 22 years and it can’t be done,” says Foilco sales director Matt Hornby.

Recalling numerous attempts to photograph the materials, Hornby adds: “Unlike other materials, where you’ve got textures, like in cloth and fabrics, foil is usually metallic or holographic, so the lights are just pinging off all over the place. We were getting white spots, and black spots, different perceptions of colour, different fractions of light. And that was a massive, massive problem.”

Foilco approached the award-winning graphics and CGI studio Where Giants Roam about producing digital assets to replicate its complete foil range. The Scottish design firm decided to take it on, despite all the intricacies of the case.

“I vividly remember that Jamie phoned me up and said: ‘We want to digitise our foils. We’ve got 270 foils we need to recreate’,” says Blair Porter, creative director of Where Giants Roam.

When he heard more about the challenges that Foilco faced in digitalising holographic and metallic materials, Porter immediately thought of Chaos. The 3D rendering and simulation specialist, mostly famous for V-Ray, developed a technology to obtain photorealistic digitalisation of the different kinds of foils.

The process of digitising the foil was anything but easy: “It’s a constant tweaking process,” explains Porter. “If we’ve got the base colour slightly wrong, then we need to compensate for the reflection colour. And we need to consider if it is glossy or if it is matte. We could spend a day trying to create a material and, on the next day, come back to the start all over again.”

One thing that is very easy, however, is the process by which designers can use that asset once it’s scanned and recreated digitally.

“It’s literally drag and drop,” says Porter. “You can just download it from the Chaos site, and you can spend hours playing with them and of course, it is perfectly accurate. It’s 10,000 photographs that go into a scan. This makes our job much more fun.”

Foilco was not the only company that adopted this Chaos technology to digitise its materials library. Winter and Company, a Swiss materials business that specialises in packaging design for luxury brands and editorial projects, also approached the software company.

Nicolai Winter, a member of the board of directors and representative of the fourth generation of the Winter family business, wanted to digitalise the company’s heritage on its 130th anniversary.

“We wanted to show the huge variety of cover materials that we have in stock on our web, and to show how they actually behave,” explains Winter.

“Now we know exactly what they look like. Five or 10 years ago, when it was just a normal website, the best thing was a good flat plane. But from a flat plane, you cannot see the exact embossing, you cannot see behaviour in light, you cannot see whether it’s glossy or dull.”

With this technology, customers can now access the Winter website, download any material, and visualise it appearing on the object they are designing, for free.

The collaboration between Chaos, Winter and Co, Foilco and Where Giants Roam, was presented during a launch event in London, where representatives from each company had a chance to explain how being able to visualise materials in their true appearance can hugely contribute to a smoother and more sustainable production process.

Technologies able to bridge between the physical and digital world hold the potential to transform the production process of packaging, from food to luxury cases for jewellery or even books – exactly those books you should very much judge by their covers.