Design Reality’s bespoke mountain bike goggles were printed on its new Objet500 Connex3 3D printer

Product design consultancy Design Reality recently invested in a new Objet500 Connex3 3D printer from Stratasys. To test what it and its material capabilities are made of, the design team undertook a product development project that scaled only three days.

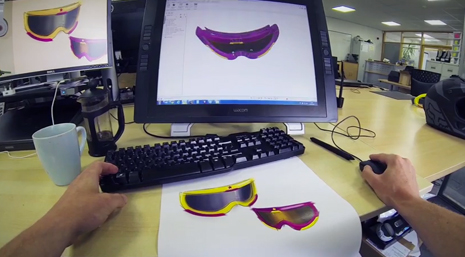

The aim was to create a bespoke pair of mountain bike goggles that went from a sketch in Autodesk Sketchbook Designer on a Wacom Cintiq 21ux, to PTC Creo 2.0 on the computer, to a 3D printed part on the Objet, and then to the Alps for testing.

The goggles were sketched using Autodesk Sketchbook Designer on a Wacom tablet

“The initial idea of doing the goggles was to choose a project that would enable us to go from concept development to prototyping and to testing in the field. This would allow us to assess Objet’s flexibility of materials, colours, aesthetics and so on,” explains Kyle Hudson, designer at Design Reality.

The starting point was the ergonomic shape of the human head. So utilising its ergonomics and anthropometrics database, Hudson was able to place the ergonomic constraints into Creo.

“That means the lens would be based upon the goggle form as opposed to basing the goggle around the lense,” describes Hudson.

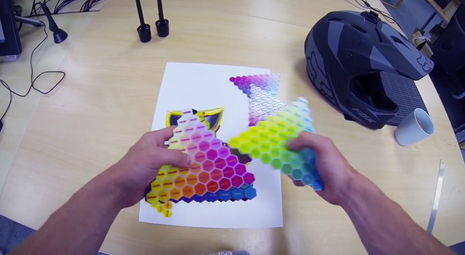

Choosing the materials for the print

Once the form was finalised the data for the goggles was sent to the Objet. The materials it was printed in consisted of 95 Shore Tango Plus Vero Magenta and 95 Shore Tango Plus Vero Yellow.

“What the Objet gives us is not only speed but also like for like materials.

“For example, previous prototyping methods would allow us to have parts the next day but they may not be representative of the actual engineering plastics. But the Objet provides like for like materials.”

The goggles in the Objet500 Connex 3D printer

Following a build period of 11 Hours 52 Mins, the goggles emerged from the Objet. Meanwhile, data for the lens was sent to the Roland MDX-540 Subtractive Rapid Prototyping (SRP) device, which cut it out in a Lexsan Acrylic.

With all parts in hand, they were fitted together including an elastic strap.

With the build complete, the finishing touches, including the elastic strap, were added

On the third day of the project, the goggles were being tested to their limits on the Alps of Chamonix.

For a condensed version of this condensed development process, watch the video below:

//www.youtube.com/embed/aNcBN_h_A3g