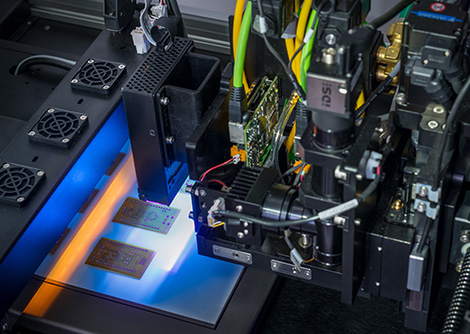

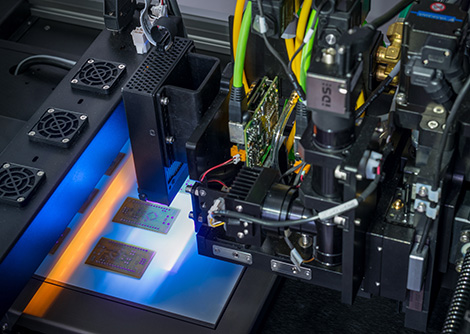

3D printed circuitboards are now a direct step from SolidWorks

A SolidWorks add-in for Nano Dimension’s DragonFly 2020 3D printer should eliminate time-consuming processes, increase design possibilities and ultimately result in the development of more capable products says the additive manufacturing company.

The add-in combines conductive and insulating materials in a single 3D print to make complex geometric structures with embedded electronics, encapsulated sensors and antennas.

“By 3D printing electronics, designers can obtain faster prototypes and work on PCBs in 3D, not just 2D,” said Suchit Jain, VP strategy & business development, SolidWorks, suggesting the process is now as simple as the ‘push of a button’. “We are proud to be partnering with an industry innovator like Nano Dimension.”

A benefit of the add-in is the reduction in the cost of errors when creating complex, geometric parts, accelerating product design and time-to-market.

Simon Fried, president of Nano Dimension USA, said: “The SolidWorks add-in for the DragonFly 2020 Pro is the first tool to enable the combination of freeform objects and embedded 3D electronics. This capability offers our customers the ability to make what is currently unmakeable [sic].

“This enables new ways of thinking, new ways of designing and ultimately, providing revolutionary solutions to some of today’s toughest product design challenges.”