Roland’s CNCs will cut everything, chemical wood, model board/foam, acrylic, a range of plastics, wood – everything except metals

Roland DG has just launched the latest in its range of benchtop CNC machines.

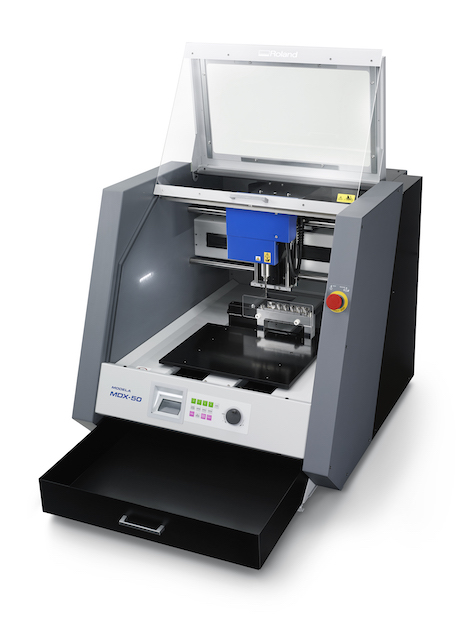

Following on from the MDX-40, the Modela MDX-50 brings the same usable build/part envelope and adds in an automatic tool changer (for up to five tools), including tool length probing and has an optional rotary axis if you fancy it.

The MDX-50 follows the form of other benchtop CNCs in Roland DG’s range, but adds automation to make its use in a professional studio more efficient

Build Space: You’ve got plenty of room to work with the MDX-50. The maximum allowable workpiece is 400mm) (X) 305mm x 135mm (Z) and you can machine everything from foam mock ups to hardwoods and harder plastics – no metals, though.

15,000 RPM Spindle: The spindle is a brushless motor, giving you 4500 to 15000 rpm. It’ll handle a range of smaller cutters with the default being 6mm shank tooling, but Roland also provide a 4 and 3mm toolholder as well – other options are also available should you need them.

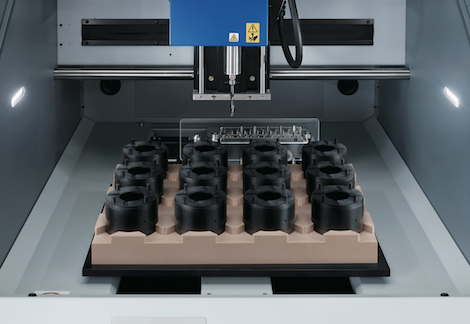

Automatic 5 tool changer: Perhaps one of the biggest bug bears of the prototyping-level CNC market is the lack of tool change automation. Roland’s higher-end machines have had this option for a while, but it’s now getting into the entry level machines too.

The MDX-50 has a mechanically driven (no air required) 5 tool changer, ready for those more complex roughing, finishing, drilling, tapping and chamfering operations. The system also handles tool length probing automatically.

On-board controller: The on board controller gives you all of your controls over the machine and will run independently. Some of the lower-end models require a constant connection to a workstation for control software to run – the MDX-50 does away with this and lets you run it independently on your machine – perfect for those with a separate workshop and office space.

The new optional automatic rotary axis gives you a bit more automation, super useful for complete prototypes (or small scale batch runs) without too much manual intervention

Optional Rotary Axis: The rotary axis is essential if you’re working with more complex forms. This will save you time and effort when rejigging parts where multiple angle cuts are required.

The optional rotary axis gives you automatic control in 360 degrees and has a decent sized vice arrangement for your workpiece.

Dust Tray & Heath and Safety: Whether you’re cutting foam, model board, machinable wax or anything else, these machines create a lot of mess. The Roland MDX 50 includes a dust tray, which makes the inevitable clean up much easier.

Additionally, unlike many of today’s desktop CNC’s Roland’s range of bench-top machines are designed for use in both the workshop and the classroom. As a result, the enclosures are safer than most, with complete interlock safety cut outs.

Software & G-Code support:

Roland’s machines are supplied with a range of CNC programming tools, from pretty basic 3-axis to more complex control over the rotary axis.

In addition, if your preferred CAM system has a Roland post processor, then you can use that as well (something we explored when we looked at Roland’s smaller CNC, the SRM-20, a little while ago)

If you’re in the UK, the Roland DG team is holding a Roadmap event, where they’re demonstrating all of its kit and its plans for the prototyping space, in its Clevedon office later this month – More details here.

Industry legend, Pat Thorn will also be on hand to answer your questions about Artec’s 3D scanning devices too!