Meyer Werft is rolling out two new Dassault solutions for cruise ship design and manufacture

Cruise ship manufacturers Meyer Werft is deploying Dassault Systèmes’ latest packaged industry solutions to aid efficient design and manufacture of its ocean-going ships.

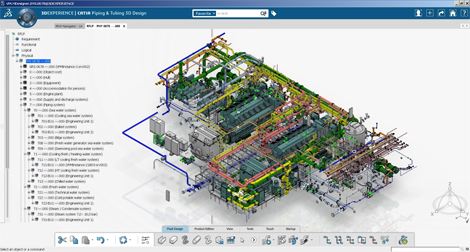

‘On Time to Sea’ and ‘Designed for Sea’ industry solutions had been deployed at Meyer Werft’s new Technology and Development Center in Papenburg which will pool most of the design and development work from its 500 designers and engineers who are shaping future cruise ships.

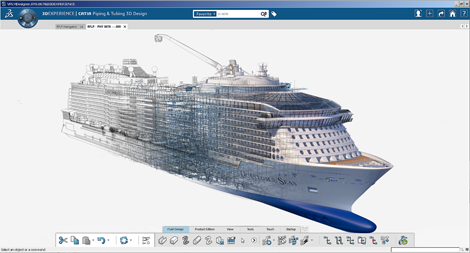

Building cruise ships is a particularly complex task compared to other industries. One cruise ship is made of more than 10 million individual parts and assemblies, compared to about one million parts for today’s largest passenger airplanes and about 10,000 parts for a car.

Cruise liners can involve more than 10 million individual parts

The complexity, diversity and large volume of data involved require efficient solutions to design and build ships that stand out from those of competitors.

The new solutions claim to offer a unified digital environment to monitor the entire lifecycle of a ship, from its construction and operation to its decommissioning decades later.

Virtual design, engineering and project management applications look to seamlessly address complex needs in product development and process requirements.

The solutions will also support additional Meyer Werft design and engineering teams in Papenburg and at sites in Rostock, Germany and in Finland that are involved in building ocean-going cruise ships, river cruise ships, ferries and other vessels.

“Since the 1980s, we’ve continually optimised cruise ship design with state-of-the-art technologies and, now, a new age is beginning,” said Meyer Werft technical director Philip Gennotte.

“Today’s shipbuilding is a highly modern industry that requires a combination of ideas, knowledge and technology in order to introduce sophisticated, future-oriented touristic concepts.”

Using the new solutions lets Meyer Werft ‘foster collaborative creativity that fulfills the highest technical demands of customers worldwide from hull shape, hydrodynamics and fuel consumption, to capacity and onboard comfort and entertainment’