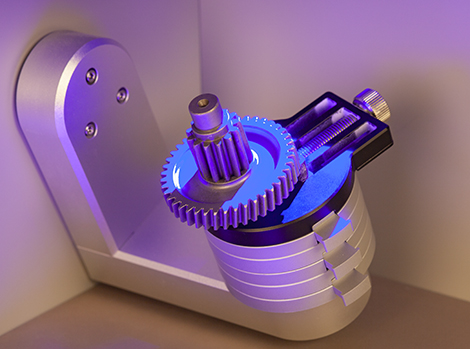

Equipped with cutting-edge twin cameras, Artec’s Micro is not only the company’s most accurate 3D scanner to-date, but its desktop presence and good looks mean that it’s a piece of kit likely to garner some admiring looks.

Complete with twin blue light scanners that are synchronised with the dual-axis rotation system, Artec suggests that the Micro creates the perfect digital copy using minimal frames.

Fully-automated, this cute little box is an industrial scanner that produces high-resolution colour scans and boasts a point accuracy of up to 10 microns, a tenth the size of a single grain of table salt.

Artec says that it has gone to lengths to make it intuitive and easy-to-use, requiring minimal training, allowing almost anyone to place an object on the scanning plate and begin scanning immediately.

After an object is placed on the circular scanning platform, the operator simply chooses from a variety of smart scanning paths and clicks to begin. The scanning process can be viewed in real-time within Artec Studio.

The final model can be exported to CAD/CAM software, including Solidworks, Control X, PolyWorks Inspector and Design X.

“This latest addition to the Artec family of scanners brings Artec into the metrology market and fills an important niche for creating extremely accurate digital reproductions of small and tiny parts,” said Artem president and CEO Artyom Yukhin.

“In fact, at a point of accuracy of 10 microns, Artec Micro is capturing details that are four times smaller than what is visible with the average human eye. Now users can 3D scan almost any object with Artec 3D’s line of five scanners; from a tiny mechanical part with Artec Micro to a jumbo jet with Artec Ray.”