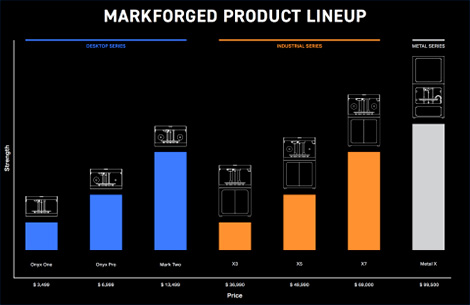

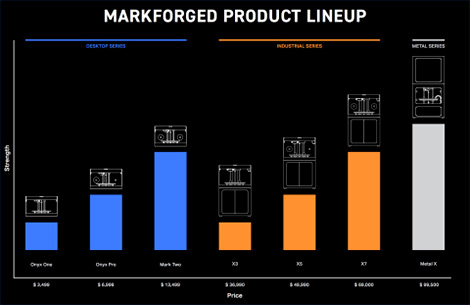

How the Markforged Industrial Series fits into the Markforged line-up, shown in orange,

Markforged has announced the addition of two new printers to its Industrial Series, the new X3 and X5 printers, specifically targeting price points to draw in more manufacturing businesses.

The X3 is powered by Onyx, a high-temperature capable carbon fiber filled nylon, letting it print engineering grade thermoplastic fiber parts, with the machine costing $36,990.

The X5 costs $49,900 and adds the ability to reinforce an Onyx part with a strand of continuous fiberglass, which Markforged claims makes the parts up to 19-times stronger and 10-times stiffer than traditional plastics.

“Local manufacturers are often at a disadvantage because they are forced to choose between the sub-par strength of printed parts and long lead times associated with machined parts,” said a Markforged spokesperson.

“With the arrival of the X3 and X5 printers, Markforged has made industrial strength printing financially attainable for every manufacturing business, allowing them to better compete on a global stage.”

The X7, previously known as the Mark X, remains Markforged’s flagship Continuous Carbon Fiber (CCF) industrial printer platform, yielding claimed 23-times stronger parts than with ABS materials, with a price point of $69,000.

Markforged maintains its ‘future-proof’ upgrade program that allows customers at any time to leverage their initial investment in an X3 to upgrade to an X5 or X7, gaining access to the extra technologies, with all Markforged printers sharing a single software ecosystem built on a cloud-based platform.

“For 30 years, 3D printing customers have been forced to accept trade-offs between strength, time, and affordability – lacking the opportunity to benefit from all three,” said Markforged founder and CEO Greg Mark.

“With the complete Industrial Series and new Metal X printer, these trade-offs no longer exist. Customers can now, with ease, print same-day parts that optimise strength and affordability for their specific needs.”