Sogeti Group (a member of the Cap Gemini Group) offers professional services that focus on three key complementary business areas: IT application management, IT infrastructure services and high tech consulting. Sogeti enables its clients to leverage global technological innovations, and achieve above average results from their IT programmes. The company employs more than 18,000 people in over 200 locations in Europe, the US and India. One third of the High Tech Consulting division’s 3,000 employees are dedicated to engineering R&D.

Much of Sogeti’s growth in the simulation field has been focused on the extremely strong aerospace sector in the region, but since 2005 the unit has diversified its customer base as other industry sectors have increasingly recognised the power and value of simulation techniques in improving the effectiveness of design and engineering processes. Sogeti has been a major user of MSC.Software’s core analysis packages and an early adopter of a number of advanced engineering techniques.

Finding a path to order

As its simulation business grew, Sogeti saw that effective management of simulation content was critical to its ability to profitably and reliably offer services to its customers. “Around five years ago we recognised that simulation content management was going to be a key issue,” explains Philippe Sottocasa, simulation Centre of Excellence manager at Sogeti’s High Tech Consulting division. “We were working with huge and sharply increasing data sets and it was becoming ever more important that our internal quality systems were extremely robust.”

Furthermore, increased globalisation is driving compliance in R&D efforts in the aerospace sector. “You might take a substantial work package and divide it up between different regions, both to reduce cost and to fulfil contractual off-setting requirements to place work in customer countries,” says Sottocasa. “You need to ensure that everyone on the project uses a constant methodology and the same calculation tools. You also need to keep a detailed record of everything that was done for audit purposes.”

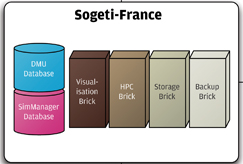

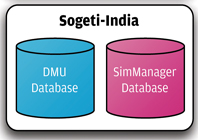

Sogeti now runs a common platform across multiple sites retaining security where needed, but ensuring flow of data and information

After some attempts to build its own data management tools using a general purpose database, Sogeti turned to MSC.Software to evaluate SimManager as a more powerful and effective solution. “We were already heavy users of the full range of MSC software,” recalls Sottocasa. “When we heard about SimManager, we realised that it was designed to meet exactly the challenge we were facing – effectively managing and distributing all simulation content, managing and automating processes, and ensuring that we could capture the pedigree of all the data we produce.”

The Solution

Sogeti selected SimManager, MSC.Software’s simulation content and process management solution that eliminates time wasted in searching for data and streamlines the process of distributing standard methods, processes, material properties, and other content. Isolated, discipline focused teams gain real-time access to simulation content and run simulations in a managed environment that ensures reliable results. And, since SimManager is capturing not only models and data, but also contextual information describing who, why, and how they were created, a complete audit trail is established for the simulation process.

SimManager solutions include:

Creation of a simulation knowledge base that facilitates collaboration and streamlines content distribution.

Managed simulation processes that improve consistency.

Automation of methods and processes to dramatically reduce repetitive, manually intensive work.

Open support of existing simulation investments including third-party CAE tools, HPC hardware and methods.

With more consistent and reliable simulation throughout the enterprise, SimManager gives product development executives the confidence to replace physical prototypes with more rapidly developed and less expensive virtual prototypes. A greater number of design possibilities can be evaluated, enabling product innovation and lasting competitive advantage.

Sogeti carefully thought through its business requirements to ensure that they achieved a robust, universally applicable and productive solution. “Before we even began to work with SimManager, we spent two years really analysing our processes and methods, talking to our customers about their requirements and doing everything we could to build the most effective system,” says Sottocasa. “The factors that make simulation data management challenging to implement are exactly the same factors that make it essential.”

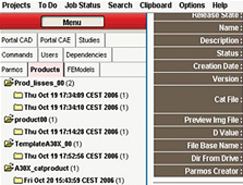

The interface through which all simulation tasks are managed, web accessible and onlineThe interface through which all simulation tasks are managed, web accessible and online

A second key element in Sogeti’s simulation management strategy has been the use of MSC.Software’s SimXpert system to capture, automate and share best practice methods. SimXpert leverages the MD Nastran multi-discipline solver engine and provides users with the ability to create and share reusable simulation templates that ensure consistent results.

For Sottocasa, the use of templates to automate simulation methodology has two main advantages. First, they help to improve efficiency and maintain quality by establishing standard practices that can often be automated. Second, templates help Sogeti to capture and retain expert knowledge inherent in existing people and processes. “It was important for us that we had a mechanism to retain the knowledge of our more experienced personnel and help newcomers to make use of it,” he says.

Building a system that met the user and management requirements of the entire organisation took the implementation team 18 months. As Sogeti investigated and documented the processes their teams used, it found that rather than simply automating a repetitive series of tasks, a system was needed that could maintain the ability of engineers to make decisions that made the overall workflow very flexible and dynamic. In addition to process complexity, there were globalisation factors affecting the company’s business. Sogeti engineers and facilities reside in France, Germany, the USA and India, requiring a solution that could scale to these global requirements. Finally, Sogeti needed to make the cultural changes required to get all its specialists used to working within the new system.

“The most powerful simulation management system in the world is no use if it is so unwieldy that your staff find ways to bypass it,” explains Sottocasa. “So it was a critical part of the implementation to build a culture of engagement, ensuring that our people were happy with the way it was all going to work.” One step to ensuring this was investment in improved IT infrastructure. “If it takes too long to check out a model from the management library, our analysts are going to become frustrated very quickly,” says Sottocasa. “So we ensured that we had the storage, network capacity and processing power to give our people improved responsiveness as part of the implementation.”

An extensive period of testing and an ongoing dialogue with users and customers also helped to refine the system. “One thing we found during testing was that although you might expect all processes to start in the same way, quite often our people were only involved in part of a process, so they needed a way of entering the workflow in the middle of a process. If the system won’t let you do that because you haven’t entered critical data earlier, then it fails.” SimManager addresses this concern by enabling flexible access to content, methods, and procedures from anywhere within the overall simulation processes.

Even the way simulation information is entered into the management system was substantially refined during the testing and implementation phase. “We started off using thin clients where our users could enter information and make requests for data access, but that proved too labour intensive and unpopular,” recalls Sottocasa. “Instead we adopted a rich client approach where the interface to the SimManager system was built directly into the user’s application environment. If they were using CATIA, they can check out and check in data without ever leaving their CATIA desktop.”

Today, Sogeti’s fully functional system controls more than 20TeraBytes of simulation content for numerous client projects worldwide. When the team began SimManager implementation, they designed in only 2TB of storage, but the dramatic growth in the power and popularity of numerical simulation, and the gains already realised in productivity, have increased storage requirements by an order of magnitude in only two years.

The Benefits

The rewards of implementation are being reaped across the entire Sogeti organisation. “First of all, we have seen big productivity gains. We now know that all simulation work is being done with the right data at the right time, so the need for any re-work has largely been eliminated,” says Sottocasa.

Project managers have benefited as the SimManager system gives them a clear view of the progress of a project. “Our project managers now spend less time chasing up their teams to find out what is going on, and more time driving their projects forward.”

Sogeti’s customers are also extremely pleased with the improvements in quality assurance that come with a documented audit trail that guarantees that correct data and best practice methods have been used. The SimManager system has even delivered savings in IT infrastructure costs. “The storage of simulation results can use up huge quantities of disc space,” explains Philippe Sottocasa. “But because we now record the precise way every simulation was conducted, we don’t need to store those results files over the long term. If we need them, we can simply re-run the simulation using the automatically retrieved data and the associated process.”

Sogeti is now making use of its own experience to help several of its customers to implement similar simulation management systems. “Thanks to our own experiences with SimManager, we are now extremely well positioned to offer this kind of help to our customers,” says Sottocasa. “Our background in simulation means that we understand the technology challenges very well and can ask the right questions, and we also now have a robust methodology for the integration of SimManager into the engineering environment.”

For Sottocasa, Sogeti’s successful implementation of the MSC.Software SimEnterprise approach is only a starting point for ambitious ongoing plans. “The time is right for a new wave of optimisation in simulation practice. The next generation of simulation processes will see 30 per cent savings in time and cost compared to even today’s best practices,” he says. “Simulation content management will be the backbone of those improvements, but what we see today it is only an essential first step.”

Now Sogeti is building what it considers to be the next stages – a comprehensive framework to manage workflow, control the use of IT resources, and ultimately to optimise the efficiency of the simulation process from end to end. “In the world of simulation and virtual product development we are moving into virgin territory once again,” he concludes. “There is a lot of work to do, and our collaboration with MSC.Software is an important component in the future success of that process.”

www.sogeti.com

Sogeti achieves new performance highs through MSC Software

Default