MachineWorks, developers of a range of software for CNC simulation, verification and polygon meshing, has announced details of an interesting project it has recently completed resulting in a new product called MachineWorks Parasolid Software bridge.

Reading the press release (found here), the details are a little obscured, but once you work out what they’ve done, the result is really interesting for those engaged in complex, multi-step machining – whether moving work pieces between orientations, different machines and between different processes.

When CNC software calculated toolpaths, an in-process stock model can be created at the end of each toolpath upon which the next operation will be based. If you’re not familiar with what this means, imagine taking a solid billet of metal, carrying out your initial machining operation to remove a large bulk of material.

The state of that billet at the end of that operation is the in-process stock model, then when you carry out the next operation, you can use this stock model to guide it.

This is typically used to ensure that your cutter is removing material, rather than cutting fresh air.

While this is a simplicistic explanation, the use of a stock model is invaluable for generation of efficient CNC toolpaths and is often a part of the CAM process.

Define the operation, the system simulates it (often using MachineWorks’ VisiCut libraries) then generates the resultant stock model which can be referenced by the next operation.

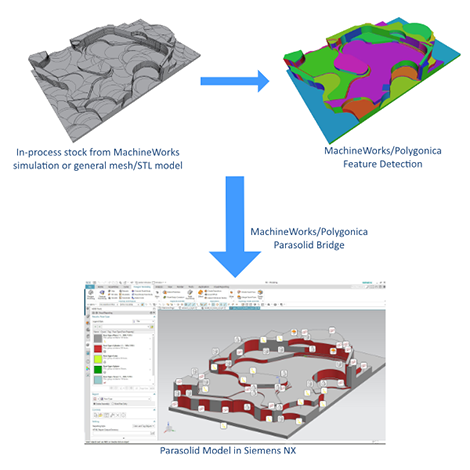

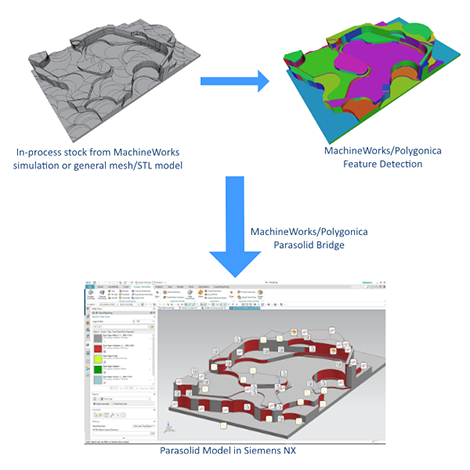

What MachineWorks has done is combine this technique with the ability to allow the use of its feature recognition software to take that in-process stock model and generate a proper Parasolid dataset from it – firstly as proper analytic surfaces (planes, cylinders, etc) or failing that, as a polygon mesh.

So what use is that? The answer is that the stock model is often trapped within the CAM workflow, only feeding subsequent operations.

What this allows you to do is to extract that stock model and use it for meaning activities around the CAM process. That might be using the data for in process fixturing. It might prove useful when machining parts that have more complex stock models (something that is useful in casting/forging applications as well as the new world of additive with metals).

It could also be used as the basis for in-process inspection.

Imagine taking a rough casting, carrying out roughing operations, then needing to fixture it up so you can add in threading operations or other operations in a different orientation – it would be difficult to gain a definitive state of the geometry of that part mid-way through that process.

As an example, a Siemens NX consultancy has just launched a new add-on for NX that does exactly this called SOLID IPW for Siemens NX.

Janus Engineering SARL are experts in Siemens NX CAM, and its managing director, Franck Paris, describes the background to the project:

“Driven by our goal of continuous improvement and innovation for our customers, we’ve been looking for a long time for solutions to improve the use of machining simulation results within NX software, a leading integrated solution for CAD/CAM/CAE from Siemens Digital Industries Software.

“We are especially interested in the case where part manufacturing requires multiple setups; our goal was to find a way of using the intermediate in-process stock from the material removal simulation to help fixture design, CMM inspection and documentation of the intermediate process steps.

“After extensive testing and exchange with the MachineWorks team, we were able to realize the full potential of their new feature detection module. This technology was exactly what we needed to obtain the required accuracy from the in-process stock to make it useful in our customers’ workflows.

After extensive testing we integrated MachineWorks and its new Parasolid Bridge into Siemens NX and we are now happy to be able to offer it to our customers.”

MachineWorks managing director Dr Fenqiang Lin, added: “This was a challenging project for us and a real test for the feature recognition in MachineWorks and Polygonica.

“We are happy to report that the mesh quality from the polygonal-BREP of MachineWorks’ Visicut engine combined with the power of MachineWorks’ and Polygonica’s feature detection algorithms delivers game-changing results. Janus Engineering are our first partner to benefit and it’s great to see how quickly they have been able to productise this technology for their customers.”