Humanoid robots can also impact the design of prosthetics and exoskeletons for humans

A project between robotics experts Devanthro and the Technical University of Munich is aiming to advance the design of humanoid robots in order for them to gain the abilities of human bodies.

The vision is to iteratively improve Roboy robotic models until their performance is comparable to humans in terms of dexterity, robustness and flexibility, utilising muscles and tendons rather than motors in the joints.

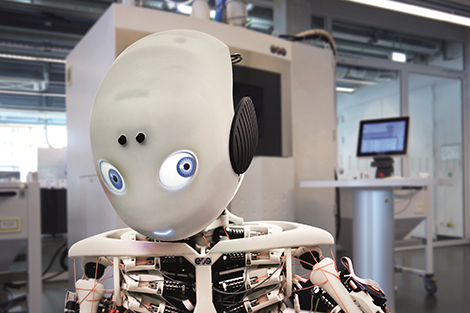

The first prototypes have lent heavily on the abilities of 3D printing, with EOS providing the complete skeletal body structure of Roboy using its SLS technology, which encases the bones and muscles.

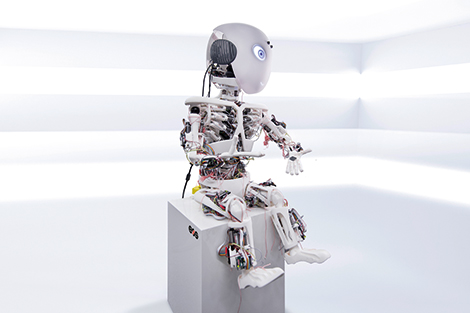

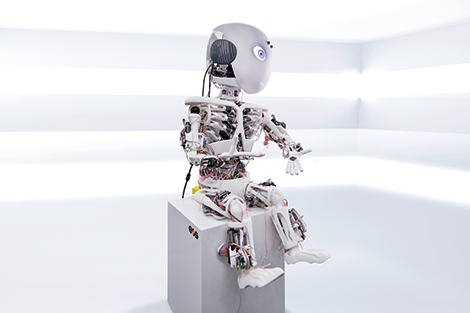

Roboy – a bit creepy

Additive Manufacturing allows for highly complex structures that are also extremely light and stable, giving the team a high degree of design freedom, optimisation and integration of functional features, and the manufacture of small batch sizes at economical unit costs.

The Roboy development benefits from all these advantages: Building complex functional geometries without classical fabrication constraints allows the Roboy team to implement functionality directly into the geometrical parts.

Consequently, build complexity is reduced, and many of the otherwise necessary assembly steps can be dispensed of.

For example, Roboy’s hands and forearms are manufactured in one piece, including several joints and individual phalanxes for each finger.

Over centuries humans have adapted the environment to fit their needs, humanoid robots can therefore fit into this environment more easily – thus avoiding expensive adaptions, and by being compatible with human anatomy, can help to augment and repair human mobility with the use of exoskeletons and prosthetics.

Want to see a little bit more? Here’s a video from Cebit a few years ago (it looks cute sat on a box in a trade show. Now imagine waking up and that thing is standing over your bed)

https://youtube.com/watch?v=avgreH_e0XI%3Frel%3D0%26showinfo%3D0

EOS CMO Dr. Adrian Keppler, said: “While a larger number of companies focusses on AI development, only a very small number of projects worldwide develop humanoid robotics.

“Therefore, we are all the prouder to support the renowned Roboy project and see its meaning. As the strengths of Additive Manufacturing lie in those areas where conventional manufacturing reaches its limitations, EOS’ technology is the ideal solution for a research project as ambitious as Roboy.”