Myself and Martyn have been pondering many things of late, but one thing that’s stuck has been the seemingly increased interest in design and manufacturing. While Mart appears to be enamoured with the Maker movement, I have a feeling in my gut (no comments please) that this isn’t anything new. Designers, engineers and manufacturers have always been tinkerers by trade and by passion. That’s why we become the professionals that we do. While I don’t think this has changed, what has changed in the wider community is that everyone else has seen the light, seen that doing things with your hands, diving in and getting a little grubby and creating something is both a distinct pleasure and a true joy. And the web is connecting everyone like never before. Oh and there’s all that 3D printing jive too.

Then you get to motorcycles, something I’ve been fascinated with for years. If I’m not working or looking to kill a few minutes while fishing that inevitable digestive biscuit out the bottom a cup of tea, I’ll be flicking through many of the blogs and other websites out there that are devoted to the subject. So it was with some delight that I discovered our interviewee, David Mucci and his first custom bike project on the rather fantastic www.bikeexif.com. I was also fascinated to discover that David is an Industrial Designer by trade – so I shot him over some questions to find out more about how he got into the project, if there was any relation between his professional work and skill set and the project for his free time and to get some insight into his workflow/process.

What’s your background David?

I’m originally from the Boston area. I studied Industrial Design at the College for Creative Studies in Detroit, and have been working at a design consultancy in Chicago for the past 3 years.

What made you become a designer?

I got lucky and was born artistically inclined. My grandfather was a craftsman and my mother’s an art teacher. I grew up immersed in art and was constantly drawing. I remember seeing a poster on the wall of one of my high school art classrooms that really inspired me. The poster was of a student sculpting a car out of clay, with the title “Transportation Design,” and some info about the school. Before that point, I had always known I wanted to pursue a career in an artistic field, but didn’t know which one. That poster opened my eyes to the world of transportation and product design. I set out searching and touring schools with ID programs, and was very impressed with CCS, so that’s where I ended up.

How did you get into motorcycle design?

Since I was old enough to drive, I had a passion for working on cars. My main interests were Volkswagen’s and BMW’s from the 80’s. I’ve always had a project car in the garage with some sort of goal in mind. In a way, they were my early design projects. I loved sketching them in different body styles and color options, then setting out to the garage to put my designs into reality. Fast forward to my senior year at CCS, and I had enrolled in a motorcycle design course. The instructor was very influential. He had a warehouse in his backyard, filled with 60+ vintage motorcycles. He would load us up with inspiration, screening old films about the Isle of Man and taking us to tour custom shops, like Detroit Bros Motorcycles. I spent the semester designing a modern interpretation of the Norton Manx. The bug had bitten hard at this point, and I found a new passion for 2-wheeled transportation.

AdvertisementAdvertisementWhat made you interested in building a custom bike?

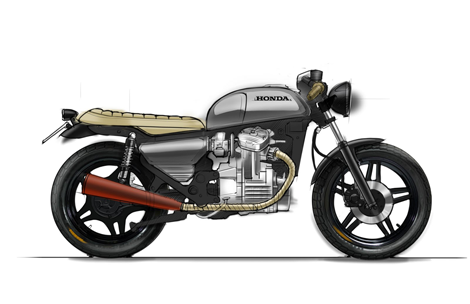

Since that motorcycle design course, I had it in my head that I wanted to have a bike project in the garage someday. I never had the money for an extra vehicle until I got my first design job in Chicago. It took a few years for me to finally pull the trigger, but in March of 2010 I picked up my first bike – a 1978 CX500 Standard. It was a great deal. The bike was fully functioning, and came with bins and bins full of spare parts, all for $700. I started out tinkering with general maintenance, but it was soon stripped down to the frame and I was sketching up all sorts of concepts.

The ’78 CX500 David picked up to start his first project

What was the process? I saw some of the concept sketches you did. What was the workflow for those?

As with anything I’m designing, I started roughing out ideas – sketching, cutting and pasting. I like to find an attractive silhouette and part break up first. These are the visual cues our eyes pick up first. If you can’t win there, then it’s already over. Where my process differed was in the restrictions a motorcycle presented. In the product design world, you’re usually designing something from scratch instead of modifying an existing object. All the changes you design in will be implemented at the hands of an external manufacturer, using lots of large scale, and very expensive tooling machinery. With the bike, I was the manufacturer, and my tool supply was much more limited. I found it easier to do a lot of my rough sketching with the bike skeleton in front of me. This allowed me to stay more “real.”

What’s your favoured conceptualisation tool? Pens/Paper/Pencils or something more digital?

When I want to get as many rough ideas down as quickly as possible, I use pen and paper. In the case of vintage motorcycles, where you’re often repurposing existing parts, sometimes it’s easier to go into Photoshop, cut up images, and arrange them in new ways. I could then use these as sketch underlays. During the refining process, I’ll usually jump into digital sketching. It’s nice to have layers you can toggle, and colors you can manipulate.

How was the process of taking your ideas into reality?

I don’t believe the design is ever done in 2D form. It’s more of a guideline; a commandeers intent instead of a direct order. Sketching over images of the bike, and while sitting in front of it, helped me stay real. This way I always had a rough plan of execution in mind. Online forums and a thorough repair manual are always a huge help on the technical side as well.

What were the biggest challenges?

Being my first motorcycle build, I don’t yet possess all the skills needed to have done this on my own. Designing the long, flat, tracker-style seat around the kinked frame of the CX proved to be the most difficult. I tried my best to illustrate what I was looking for, and with the fabrication help of Tony Prust at Analog Motorcycles, we achieved a solution I’m very happy with. I’m now enrolled in fabrication courses at a local college, and plan to implement these skills in the next upcoming build.

The Motorcycle blog world seems to have gone nuts (and rightly so) for the CX project. How does it feel to have not only your work, but your own personal project, pawed over in a comment stream?

It’s an incredible feeling of relief. When you’re a new guy in any customization scene, you never really know how your work will be received. You always run the risk of stumbling into some huge faux pas that overshadows the entire project. The positive side to having minimal knowledge of existing trends and commodities is you’re less likely to fall into a rut. Project managers in the design world will use this tactic when briefing designers on a new project. Make the guidelines as brief as possible and you’ll get the broadest range of concepts. Implement too many restrictions and you’ll end up restricting the designer’s innovation. I still see my build as being pretty basic, I just tried to make the most out of what I had and aimed to get it done in 3 months so I could ride it. I’m really overwhelmed with the amount of positive feedback I’ve received. I think I’ll stick around for a while. I like it here.

Do you think that you’ve learned lessons with this personal project that you can carry over into your day job?

I would say my design background is what assisted the build, instead of the other way around. I went about it using the same design process we use in the field. It’s hard to carry over what I learned about metal manipulation, carb flow passages, and fluid viscosities and apply them to designing a new set of chef knives. The new skills and knowledge I acquired were much more mechanical than process driven.

So what’s next? have you got the bug and have another project planned or are you just going to ride it and enjoy all the hard work?

As with all my previous car projects, the money pit never stops. After a season of riding on the back of the CX, my girlfriend was influenced into picking up her own bike. There’s now an ’81 Yamaha SR250 sitting in my garage, ready to be dismantled. I’m planning to have it done by next spring so she can learn on it. As for the bug, yes, I’ve definitely got it. In my off time, I’m working on building a future that involves motorcycles, but for now, I’m concentrating on the next build and will go from there.

Any tips for someone that’s thinking about a similar project?

This is a pretty specific tip, but I’ve been telling everyone who asks me that question: If it’s vintage, and if it’s your first bike, Less Carbs = Less Headaches. As for design tips, always take a step back to view the full picture. Aim for an overall aesthetic and make decisions based on your initial vision. It’s easier to start with a plan, and the outcome will be more cohesive.

David is detailing the design and build process of his girl’s bike on his rather inspiring blog www.moto-mucci.com. But do you have a project that you’re working on in your spare time that you think other designers and engineers would be interested in reading about, that you’re proud of? Get in touch and we’ll have a yap.