We’re seeing a boom in desktop, home or workshop friendly 3D printers – the rise of the MakerBot is unstoppable or so some would have it. Additive Manufacturing, 3D printing, whatever you want to call it, is here to stay, but alongside the process and material issues involved in these small form factor wonders there’s an issue. A big one.

Both literally and metaphorically, however you cut it, how you dice it up: 3D printers are small and they build small things. What if you’re a startup looking to manufacture larger components on a budget? What if you’re looking to use more traditional sheet materials? What if an eggcup isn’t your sole business interest?

While the 3D printing world moves on, there’s many forgetting the age old CNC mill or router.

There’s been a move to bring more affordable laser cutters to market and there’s a number of projects in the works to do the same to the CNC mill as MakerBot et al have done to the RP machine, but again, size is the limiting factor. Into this comes a London based designer, Michael Warren of Michael Warren Design. He’s currently working on Grow. And I’ll let him explain.

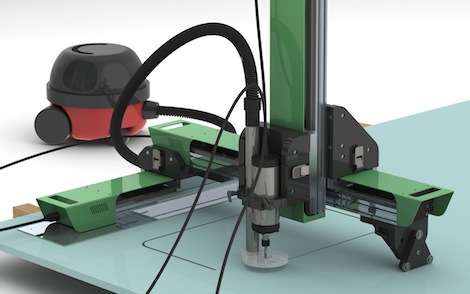

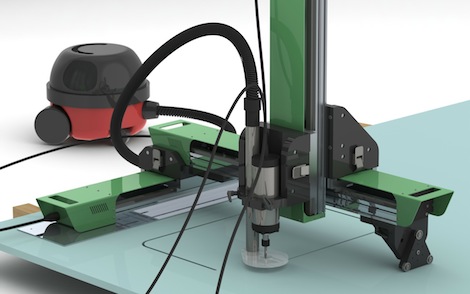

The project is called Grow CNC. Grow is the worlds first portable full size CNC router. Designed to cater to a new emerging professional user.

The project is still in its infancy but it is moving forward quickly.

If you fancy seeing how this bad boy works, then Michael has a demonstrable prototype ready and he’s made a rather nifty little video to show how it works.

Grow: A portable, professional, expandable CNC router system from MichaelWarrenDesign on Vimeo.

The specs and workings look a little like this

Portable

The whole system folds down into two flight cases.

Grow is the worlds only portable full size CNC router. Grow fits compactly into its own wheeled travel case. It can be setup by one person and be ready for use in under 2 minuets.

Professional

Designed with the professional user in mind with an emphasis on new user groups. Grow is easy and fast to learn. Simplified software, including an iPhone App allows progressive levels of use. Experienced CNC operators will understand it and new users will pick it up rapidly.

The design incorporates a number of features that make it work efficiently, and a joy to use.

- The floating slave wheel allow the machine to work around obstacles and move smoothly over rough materials

- Magnetic self-locating quick release assembly brackets that accurately align the machine during setup. whilst allowing you to keep your hands free during assembly

- Always within reach onboard tool storage

- Probing plate and iPhone companion App provide a quick accurate setup away from the keyboard

Expandable

The machine ‘Grows’ to suit user requirements as they expand. Affordable extended linear guides can be quickly switched and used. Different tool heads and be fitted.

Other details

According to Michael: “The standard machine working area is 500mm x 500mm, but yes the machine can Grow to almost limitless length in the X axis and 1600mm> in the Y axis (able to work standard 5′ x 10′ boards). At the moment the machine can’t cut metals because of coolant issues. But it is very happy cutting plastics, woods and solid surface materials like Corian etc.” In terms of pricing, nothing is set, but Michael’s aiming for around the £6-8K. It’s not a cheap machine, but compared to other tools that can work with these types of volumes, then it’s much more cost effective and can be expanded (presumably with large sections in the axes.