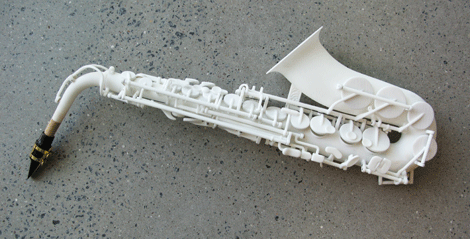

Printed using an SLS 3D printer, this saxophone weighs only 25 per cent of a standard instrument

Our favourite musically-tinged professor, Olaf Diegel, has been 3D printing yet more musical instruments – this time spending the last six months creating the world’s first 3D-printed saxophone.

The professor of product development at Lund University in Sweden has previous form, with guitars, drum housings and other instrument casings, but this time set the challenge to 3D print an instrument usually cast from brass.

Built from 41 different components using an SLS printer, it weighs less than 25 per cent of a real saxophone (and frankly, sounds horrendous*). But not to be stalled, Olaf is already planning another prototype, with both mechanical and aesthetic improvements.

//www.youtube.com/embed/6qNQ5NobrAY?rel=0

“The next version will be even better looking, as 3D printing allows me to create shapes that would be impossible to make with traditional manufacturing”, states Olaf, pointing out that a couple of the notes are slightly out of tune because of air leakages.

Ever enthusiastic, Olaf is convinced that one major advantage of the method is customising instruments to individual needs.

”One day, we could see people starting to get involved in the design of their own products so that the products suit their needs or personalities better.”

Take a look at Olaf’s electric guitar here, or how Fender are using 3D printing for its guitars.

*The author is qualified to say this. There’s not much to do in Cumbria growing up – it’s a case of learn a woodwind instrument or bother livestock…