Here’s something you don’t hear me saying very often: “let’s talk about Data Management”. Sounds a little sarcastic, doesn’t it? Well, this time, I’m deadly serious.

Data Management has become a key focus for many organisations. Ensuring that all those involved in the product development process have access to the latest revision of data will not only save time but will also result in increased productivity.

Surely if all data is controlled and centralised then everyone will be able to find and reuse information more easily and readily? But there’s one big problem: Data Management, in the vast majority of cases, is a royal pain in the backside.

It’s a pain in the backside for those authoring and editing the data (the designers and engineers) as well as for those consuming the data, whether that’s those in management, on the shop-floor, in the purchasing department or, God forbid, human resources.

Does it have to be this way? Do we have to spend hours filling out forms, uploading data or navigating overly complex search dialogs to either create or find the data that’s central to the task at hand? No, I don’t believe we do, and what’s interesting is that the folks at CSI agree with me.

For those unaware of the CSI company, it’s a data management specialist that’s been around in one guise or another for more than a decade. Its flagship product, DesignDataManager, started out life as an ultra efficient workgroup data management system for the Pro/Engineer community, offering a less complex and, frankly, less expensive alternative to the likes of Pro/Intralink.

It’s been through some major updates over the last ten years that have seen it evolve from a basic version management of Pro/E data, to become a well developed heterogeneous data management workingsystem.

Now it features not only data versioning and revision management, but also true lifecycle management in terms of formalised workflows for ECO (Engineering Change Orders) and ECNs (Engineering Change Notices), BOM (Bill of Materials) management, business system integration (to things like ERP) and web-based collaboration with the extended enterprise.

What’s interesting to me is that the CSI team has managed to do this without dramatically increasing the cost of the system or its complexity. So, let’s start with perhaps the most complex part; implementation.

Implementation

DDM is designed to be implemented in a very short space of time and doesn’t have complex server requirements.

Essentially, the base level is a workstation that runs Windows 7, XP or Vista, and then moving into Windows Server territory once 10 users are exceeded.

Once the server machine is ready, you can set it up, connect to clients (it integrates with AutoCAD, SolidWorks, Inventor, Pro/Engineer, Solid Edge and IronCAD) and you’re ready to go.

In terms of implementation, the user access is defined using a groups and roles-based approach that not only makes initial implementation easier, but also on-going maintenance as, for example, users are added and removed or access requirements are changed.

This ease of use and maintenance is continued into one of the typically most critical areas of any PDM or PLM implementation project, workflow creation.

Whether you’re looking to replicate existing ECO and ECN processes or to rationalise these with the advent of digital practices, the definition process is pretty simple and conducted using a graphical flow-chart style scheme.

This not only means that it’s much clearer when initially setting it up (defining those stage gates, decisions, roles, responsibilities and the flow of data through a process) but it also means that its immediately clear when changes need to be made or new processes created.

Also worth noting is that DDM has pretty extensive support for classification, which many organisations are now getting interested in, not only a means of both categorising data and parts, but also as a means to do very quick search results. In the world of DDM this is referred to as Categories.

User experience

While implementation is key to ensuring that any PDM/PLM system works in terms of process and workflow, the real adoption is driven by one thing: user experience.

This not only includes the user interface and how the system works, but also the experience the user has when operating the system.

Generally, user experience isn’t as a high-priority in most PDM/PLM vendors mindsets but the fact is that unless you make such mission critical systems easy to use and engage with (for all levels of user), they’ll perceive it as that pervasive ‘pain in the arse’ and do their damndest to work around it.

This is something we hear from engineers and designers every time they get involved in data management projects and is a commonly quoted reason as to why data management implementation projects fail.

Simply, the users don’t actually want to use it because it either takes too much time, is too restrictive, or is seen an enforced decision against which they react.

Again, CSI has realised this and made the user experience within DDM much more accessible. Take the client application as an example. It provides a clear user interface layout, one with which many will be familiar.

To the left are a number of panels that give access to the current Workbench of files, which shows tasks at hand, data that has been checked out and such.

There’s also a Saved Searches (ala Outlook), Favourite Categories and Folders as well as a very useful My Recent Items list (something I’m surprised more PDM/PLM systems don’t have).

Search flexibility

The key part of the DDM interface is the small strip across the top, which contains two search fields for Name and Description then a filter for Status.

Below this is the results viewing panel, so when you click on a search result a thumbnail comes up with a summary of the metadata that object holds.

When looking for something, you punch in the search string and the system will stream those results into the window.

Data entity types are clearly flagged up as to their type and status giving you a good idea of what is being looked at before you even think about loading it.

Of course, more advanced searches are always going to be required, so there’s a more detailed, advanced search page available too. Both simple searches and more advanced ones can be stored in your Favourite Searches folder.

It’s also possible to store company-wide standard searches that everyone has access to, which could be useful for search strings to standard parts, inventory, etc.

In use

The manner in which you work with DDM varies depending on your workflow and role.

For a CAD user, there are integration plug-ins available for SolidWorks, Inventor, Pro/Engineer, Solid Edge, IronCAD and AutoCAD at present. There are also plug-ins for the Microsoft Office suite of products.

Then, as well as the client application, there’s also a rather nifty widget that sits either in the task bar or on the desktop into which files can be dragged and dropped.

This kicks off the data import process; you fill out the details, assign any classification/categorisation and from then on, its managed and shared data.

Workflow management

Alongside the search functions, there’s a whole host of workflow management tools.

DDM has a pretty slick workflow creation tool that lets the user define the routing and decision/approval process to match their company’s requirement.

So simple in fact, the system can be administered by either the IT support on site or, as is common in many smaller organisations, by a knowledgable user.

This saves a fair bit in implementation costs as well as on-going costs, as workflows can either be adapted when required or new ones created (perhaps to enhance an existing workflow or to gain control of another process).

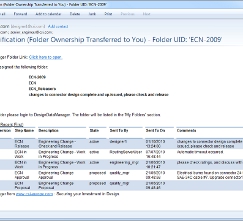

A key part of this, and something I found interesting, are the notification tools available. As with most PDM/PLM systems, DDM integrates with the user’s email system to control the flow, assignment and approval of work tasks.

The email notifications are key to this and within DDM, they’re rather elegant. The email format has been optimised to not only present the task and decision at hand, it also provides a visible COMreport on the status and previous stages in that task’s development.

One thing worth noting is that it can also be used on portable communication devices, whether that’s a Blackberry, iPhone or Windows phone. Considering the prevalence of these devices, that’s key.

A final aspect on the workflow front brings a level of realism to the whole system. Despite having tight security and workflow controls, the fact of the matter is that occasionally data can become stuck, assigned to a single user, checked out of the ‘vault’, or else a team member goes on holiday, leaves the company, falls ill or even worse.

As a result, the ability to dive in and override data control is key. This can be done manually or on a time limit to ensure that data or indeed, critical decisions, don’t get stuck.

BOM editor

The current thinking is that the ability to manage the multiple types of BOMs in the PDM system is the next stage in data management’s evolution at its core level.

While many existing solutions allow the user to extract the BOM based on the 3D assembly, these often don’t exactly match the requirements. Items, often referred to as non-drawn items (lubrication, adhesives, packaging etc), aren’t easily stored in the CAD tool and so require manual addition.

DDM allows the user access into a product structure in order to add them this guarantees they are always maintained and the BOM represents the whole state of the product more clearly.

The user is even allowed to pull those items in from the library, ensuring company standards are maintained.

Business integration

The last topic I’d like to cover is integrating data management into the enterprise.

Although for some, the CAD integration and client application will be the most commonly used method of interacting with data, what about those without the need for a heavy client – whether that’s other departments, clients, customers or suppliers?

The answer is the DDM Web Client. This is, as you’d imagine, a browser-based client that gives a stripped back version of the DDM client, but one which is enabled for a much lighter weight experience.

The user simply loads up the web-address, logs-in and it’s ready to go, whether that’s on a workstation or, as we’ve already discussed, using a mobile device.

Finally, while data management is key to product development, the fact is that many organisations have other business systems that can benefit from the data locked into the data management system, specifically, ERP systems.

To assist with synchronising the two, there’s the DDM Enterprise Update utility.

This publishes XML-based BOM information (as well as more detailed information such as drawing PDFs and such) to a specified ‘watched’ folder that can be read by the ERP system at preconfigured times.

Of course, manual updates can also be done, if the ERP users need to be working on longer lead-time objects.

Conclusion

It may sound obvious but usability is critical in any application, but never more so than when it comes to data management.

However, some vendors miss the point entirely by making their systems so overly complex and unintuitive that users actively avoid using them unless absolutely mandatory.

By simply adding some enjoyment and ease of use to data management tools the CSI team have removed that hefty barrier and built a system that’s not only engaging from the user’s perspective, but one that can be maintained without the need for consultants or dedicated IT personnel.

To my mind, that means the system does not only add to an organisation’s effectiveness by providing centralised, managed data and process, but also by engaging with the those that make the system live and breathe.

The good news is that DDM is available for the majority of CAD users and it’s affordable. With that in mind, I can’t fault it at all.

www.csi-europe.com

| Product | DesignDataManager 2010.2 |

|---|---|

| Company name | CSI |

| Price | From £600 |