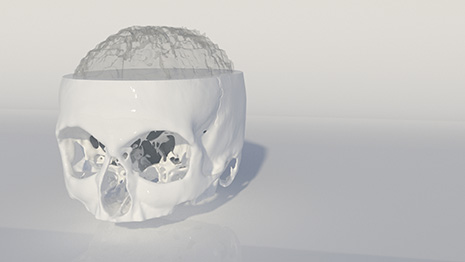

3M BIC utilises 3D printing and VR in a project that demonstrates maxillofacial reconstruction as a way of repairing broken bones

Using the data from an employees’ CT scan 3M Buckley Innovation Centre (3M BIC) 3D printed two life-sized skulls – one using SLS and the other FDM technology.

With this in-house project the Huddersfield-based design team aimed to demonstrate how 3D printing has advanced and the impact it can have in the medical and healthcare industries. In this particular instance, the reconstruction of a damaged skull.

In addition to the 3D prints the team has since converted the files for use in virtual reality applications, including the Microsoft Hololens.

The original process of converting the raw data from the MRI (DICOM data) to a 3D printable file, Paul Tallon, consultant designer at 3M BIC, and visualisation assistant, Luke Phillips, used a free software called OsiriX to assemble the layers of the scan and create a 3D model.

This particular software allowed them to choose parts of the scan determined by the tissue density i.e. bone, muscle, skin or vascular tissue. In this case, the team chose to focus on the bone density.

They then exported the CT data file as an STL and imported it into Autodesk 3DS Max.

There were a few inaccuracies with some surfaces due to lack of data, which had to be corrected. To do this, they used a combination of ZBrush and 3DS Max, designing implants in 3DS Max to cover these surfaces, which were then imported into Z Brush to smooth the implants into the model.

The team printed two life-sized 3D skulls using SLS (left) and FDM (right)

The first of the two versions that were printed was created using an SLS powder print composed of a nylon powder (pa2200 polyamide) printed on an EOS p110 housed on the 3M BIC’s Innovation Avenue.

The other version was an FDM print from the latest generation of MakerBot printers using PLA (polylactic acid).

The SLS version of the skull has the greater detail, however, the FDM print, which took over 50 hours to complete, highlights the advancement and future possibilities of FDM printers.

The team also recently converted the files so that it can be used in VR

Dr Michael Wilson, centre manager at the 3M BIC, said: “Our Skull project is not only a great showcase for 3D printing, but also underlines how 3D design can be incorporated into the healthcare industry. If doctors can view CT and MRI scan data more freely in 3D it would give them a greater understanding of a patient’s condition and refine the process of reconstructive surgery.”

“If someone fractures their skull, for example, then a scan can be used and translated into 3D. A copy of the undamaged side of the skull can be printed in titanium and then attached to repair the damage caused in the patient’s skull.”

The 3M BIC in-house design team is currently looking at MRI scan data of the shoulder and wrist of a retired rugby league player.