Finally launched, Carbon3D’s CLIP 3D printing technology has everyone excited

Carbon3D has finally emerged from the shadows to launch its take on polymer-based 3D printing – and it’s fast, like really fast.

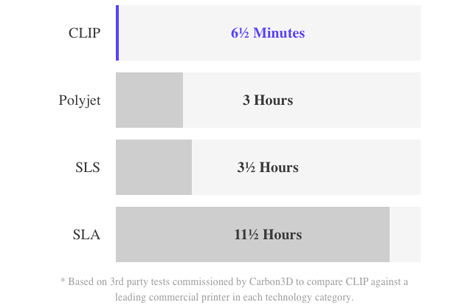

Comparative test figures announced by Carbon3D suggest that a model that takes over three hours to print on a SLA machine, can be produced using its technology in less than 7 minutes.

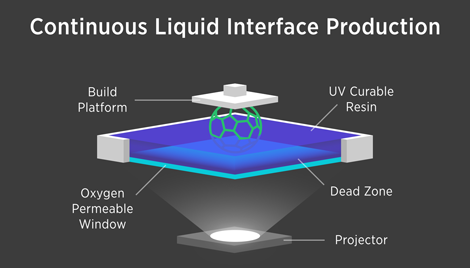

Its Continuous Liquid Interface Production technology (CLIP) harnesses light and oxygen to continuously ‘grow’ objects from a pool of resin instead of printing them layer-by-layer.

https://youtube.com/watch?v=UpH1zhUQY0c

The times for this process are blisteringly fast, especially when coupled with the finish of the parts

By carefully balancing the interaction of UV light, which triggers photo polymerisation, and oxygen, which inhibits the reaction, CLIP continuously grows objects from a pool of resin at speeds 25-100 times faster than traditional 3D printing.

Excitingly, the CLIP technology isn’t simply about speed – the finish of the printed objects we’ve seen is extremely good due to a noticeable lack of layering.

Where existing 3D printing technology is repeated layers, Carbon3D uses a tunable photochemical process instead to allow for a layer-less and continuous process that eliminates layer stepping.

Already there are some exciting material properties available, including being able to add elasticity, stretch, or dampening to a part.

At the heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens. By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photopolymerization cannot occur.

As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone.

How the CLIP technology works

Conventionally made 3D printed parts are notorious for having mechanical properties that vary depending on the direction the parts were printed because of the layer-by-layer approach.

Due to continuous forming, CLIP produced parts should therefore be more consistent and predictable, and in a way similar to injection moulded parts – smooth on the outside and solid on the inside.

The technology was originally developed by Professor Joseph DeSimone, Professor Edward Samulski, and Dr. Alex Ermoshkin at Carbon3D, based in Silicon Valley, founded in 2013 in Chapel Hill, NC.

We alluded to this technology in our 2015 3D Printing Preview having had a sneak preview of what it could do late last year, but it’s hard to imagine the kind of shake-up this will mean for the industry.

First, the major companies will take a line similar to HP’s announcement – that no machine has yet been built – however we know of Carbon3D Beta machines working in bureaus in the US that are already getting the job done.

While the finical clout of HP might have woke the industry up from a plateau of living on the hype of the mainstream media, this announcement should have the R&D departments of Stratasys and 3D Systems working overtime. All of which is great for us.

Secondly, it’s proof that the next big leap in 3D printing technology can still come from out of the blue.

Carbon3D is not a company from the initial founding fathers of the technology, but one built on fresh ideas and possibilities unlimited by 30 years of existing technology.

It’s all rather exciting, and we’re extremely optimistic about what this will bring for all industries and sectors looking to harness 3D printing.

We’ll have more from Carbon3D in the coming weeks, so stay tuned.

Want to know more about what 2015 will hold for 3D Printing? Read our top five trends to watch out for, here.