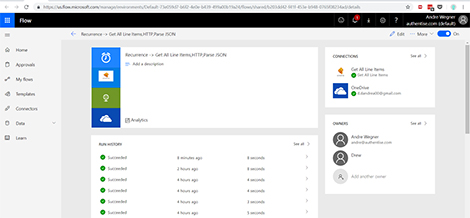

Authentise, a creator of data-driven workflow tools for additive manufacturing, has agreed to a multi-year collaboration with Microsoft to utilise Microsoft Azure and integrate its workflow management system into Microsoft Flow.

The integration should give operators directly involved in additive manufacturing quoting, production and analytics processes the opportunity to create their own automations without any coding knowledge.

Flow allows them to connect Authentise’s data with third-party applications such as Microsoft Office 365, Quickbooks, text messaging, email and more, simply by dragging and dropping the operations into place.

In doing so they can create custom alerts, dashboards, and other workflow automations to further increase transparency and efficiency in their additive manufacturing operations.

“We’re delighted to be working with Microsoft to put power into the hands of operators,” says Authentise CEO Andre Wegner. “Our work has shown us how creative those involved with additive production are, and how that ingenuity is often stifled within their operations. Yet, there are many ways in which they could improve their daily operations with zero risks. Thanks to this collaboration, we are giving the power to make those changes to anyone, no matter their background.”

“Danfoss’ additive operations have quadrupled over the last year,” reports Werner Stapela, Global Head of Additive Design & Manufacturing at Danfoss. “Working with Authentise has helped us manage that workload, but every operator has slightly different requirements and preferences.

“Giving individuals within any part of the additive workflow the opportunity to craft their own automations is the only way to ensure that the production processes is working as smoothly as possible. We’re delighted that Authentise and Microsoft have recognized this and are providing our staff with the necessary tools and integrations.”

In addition to the integration with Flow, Authentise is also switching its existing customers to Azure.

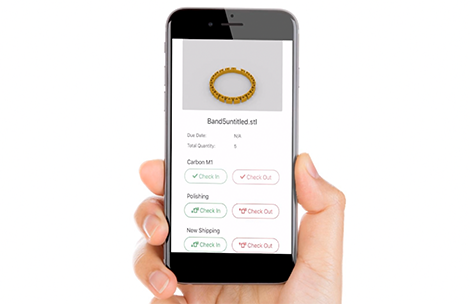

Elsewhere, Authentise is looking to extend its digital thread from the printers data to every post processing step with the launch of a new app for mobile devices.

The app uses scans of QR codes implanted on travelers to help operators move parts through manual post processing stages such as powder or support removal, inspection, testing and more.

This should make it easier for operators to track parts in progress, which in turn allows managers to see order progress and increases detail on traceability report for customers, with the actions generated also being used in Authentise’s Machine Learning algorithms to improve time estimates, quality predictions and more.

“Despite the fact that additive devices are nearly entirely digital, the entire process is far from it,” says Wegner. “Our software already retrieves data from more additive devices than anybody else, as well as some post processing tools, but that’s not enough. Manual process steps are tedious enough for operators; reporting their progress shouldn’t be.

“By releasing this app, we’re simply doing what we always do; focus on making the life of the operator easier. The fact that we’re using the data generated to add further value is just added bonus.”

The App will be available as a trial release in the Google Play store or via the web. In addition, Authentise has released a minimalist traveler that allows additive manufacturing facilities to start the process of going completely paperless.

Additional functionality will be released in the coming weeks, including the ability to add attachments such as images and notes to each production step, and the ability for operators with the right permissions to jump and undo process steps.