FluiDyna’s technology uses Graphics Processing Units (GPUs) as massively parallel processors

Altair and German company FluiDyna, a developer of native GPU-based fluid dynamics, have announced collaboration plans to develop GPU optimised Computational Fluid Dynamics (CFD) applications.

For computational intensive disciplines like CFD, FluiDyna’s technology uses Graphics Processing Units (GPUs) as massively parallel processors, offering the benefits of being less expensive, faster and more energy efficient than Central Processing Units (CPUs).

In addition to a new virtual wind tunnel technology later this year, Altair will be the exclusive worldwide reseller of FluiDyna’s ultraFluidX and nanoFluidX CFD technologies, as well as providing via its Altair Partner Alliance program to HyperWorks clients.

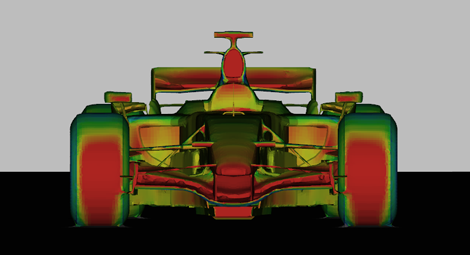

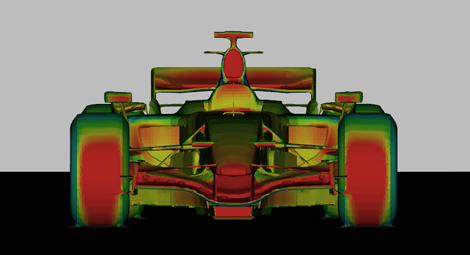

The link up aims to provide solutions tuned for external aerodynamics with fast computation

“FluiDyna’s technology and expertise complement Altair’s CFD offerings by providing yet another methodology particularly tuned for external aerodynamics, fast computation and our core strength in optimisation,” said Altair CTO Uwe Schramm.

“The collaboration between our CAE (HyperWorks) and HPC (PBS Works) development teams with FluiDyna’s experts will offer new and exciting opportunities to expand our product portfolio that is taking advantage of GPU-based clusters and supports green computing initiatives.”

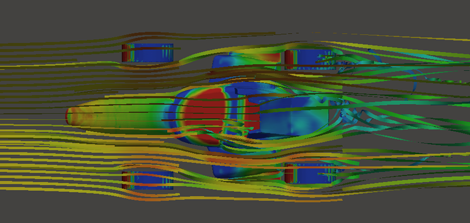

Based on the Lattice Boltzmann Method, ultraFluidX solves large scale internal and external aerodynamics problems quickly on a single workstation for a broad class of problems, including passenger and heavy-duty vehicles.

NanoFluidX is a fluid dynamics simulation tool based on the smoothed particle hydrodynamics method to predict the flow in complex geometries with complex motion. For example, it can be used to predict the oiling in powertrain systems with rotating shafts/gears and analyze forces and torques on individual components of the system.

Back in 2010 we saw FluiDyna working alongside visualisation specialists RTT (now Dassault Systèmes 3DExcite), blurring the lines between visualisation and simulation, powered by Nvidia GPU power.

We were presented with a high-quality rendered model of a car with an animated CFD analysis showing the airflow around the wing mirror. While this may sound like nothing special, the difference here was that the simulation and rendering were both being calculated and displayed in real time.

The designer could inspect the 3D model from any angle, zoom into see detail, and take a closer look at how the velocity distribution changes as the car travels at different speeds.

Naturally, the hardware making this happen was pretty substantial – a workstation with three Nvidia Tesla GPU cards.

Fluidyna at the time said said that with this setup calculations could be completed 60 times faster than when running on a single CPU.

Although Altair does not hold the same high power rendering technology, time will tell whether it sees the need for realistic visuals within its products.

With the arrival of MSC’s more visually capable Apex software, and the stunning simulation work RTT has gone on to help develop with new parent company Dassault Systèmes alongside Honda, the influence of GPU processing within simulation is clearly increasing.

The role of GPU power for simulation is increasing, as 3DExcite and Honda demonstrated with its crash test simulation software Real Impact