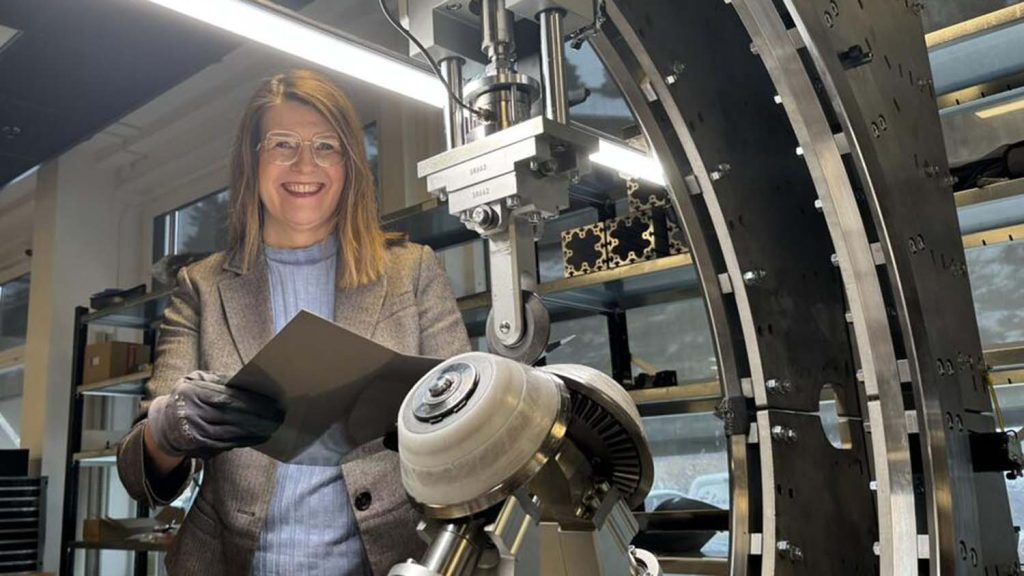

Mobility giant Alstom is deepening its collaboration with Swedish sheet metal forming start-up Stilfold following a successful pilot, evaluating how to use its technology for more train components and structural elements.

Stilfold’s system is based on bending and folding steel sheets in a controlled, origami-like process using robots. The technology opens up new ways of designing steel components, with the potential to both reduce climate impact and lower costs.

The steel requires less processing, such as welding, which reduces both energy consumption and environmental impact. At the same time, material strength can be improved despite the reduced material usage, and structures can be made significantly lighter than with traditional methods.

“Through the pilot project, we have been able to confirm that Stilfold is a highly promising technology with potential across several types of train components. The results allow us to take the next step and deepen our collaboration with a view to identifying solutions that are both more environmentally friendly and cost-effective,” said Ganesh Chandramouli, head of innovation, strategy and product portfolio at Alstom Sweden.

In the next phase of the collaboration, Stilfold and Alstom will analyse additional existing solutions and identify components where the Stilfold technology can have the greatest impact – for example through weight reduction, simplified manufacturing or reduced climate impact.

“This is exactly the type of industrial validation for which we have built Stilfold. Taking this step together with Alstom from pilot to broader application confirms that our technology has the potential to redefine how steel components are constructed and produced,” Stilfold CEO Jonas Nyvang.

Through Alstom’s Innovation Station in Sweden, and in collaboration with universities, research centres, start-ups and other industry partners, Alstom says it is building a strong innovation ecosystem in Sweden as well as across Europe.