Having arrived at a design for a device to reduce the possibility of suffering a Deep Vein Thrombosis (DVT), RBR Active needed to take it a step further and ready its Legflow product for manufacture.

The idea behind the device is to use it to carry out three simple foot exercises, leading to a claimed 11-fold increase in blood flow to the lower limbs – with its compact size making it effective anywhere during long periods of inactivity such as air travel, working in an office, being in hospital, or just through prolonged sitting.

This tough product would need to be injection moulded form polypropylene, so RBR contacted Fenton Precision Engineering in Northamptonshire to help design its idea for manufacture, bringing the concept to reality in under 11 months.

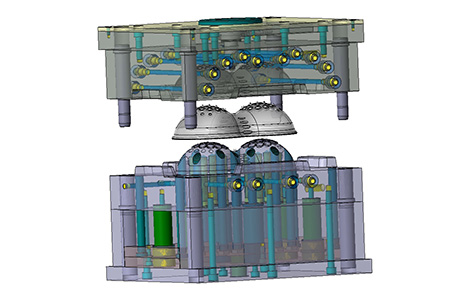

The mould tool for it was designed in VISI, and cut from P20 tool steel on a Dugard CNC machine programmed with WorkNC – both software solutions from Hexagon Manufacturing Intelligence’s Production Software stable of products.

“We suggested it would be better to mould it as a one-piece product,” says Fenton technical director Richard Brown. “VISI’s reverse engineering capability was essential, to take the point data from our CMM and combine surfaces and solids, and seamlessly work between the two.”

The wall section at the top of two dome structures on the product, which contains 38 nodules, had to be particularly thin to allow flexibility. “But there’s obviously a limit as to how thin we could make the wall. We got the optimum thickness through VISI Flow Lite, which simulates the filling phase of the injection moulding process.

After all the initial moulding criteria and gating positions were added, the software was used to achieve a well-balanced filling of the cavities under optimum manufacturing conditions.

3D prints of the product were made as prototypes before any metal was cut, allowing for a few last minute design changes, before the tooling around the product was created using VISI Mould, and its built-in Meusburger catalogue for the native parts.

Due to the radius shape of the Legflow product, the team at Fenton decided that holes for the eight ejector pins should be produced using their wire eroder after the main surface had been machined on the Dugard.

Comprising of around 30 different components, the complete tool manufacture took around six weeks; the cores and cavities were machined through WORKNC, with each plate taking around 25 hours, and a further 20 hours for the build.

“It was quite a complex format, with a lot of small solid carbide cutters from a variety of suppliers,” said Brown.

“We also used shrink fit tooling to ensure grater accuracy, balanced chip loads, better finishes, and increased speed and feed rates.” And he says WorkNC’s ability to produce high quality surface finishing kept any additional polishing to a minimum.”

On Fenton’s recommendation, SteriTouch antimicrobial master-batches were added, to protect the product against bacteria, biofilm, fungi and mould, particularly important for a product that will come into contact with skin.