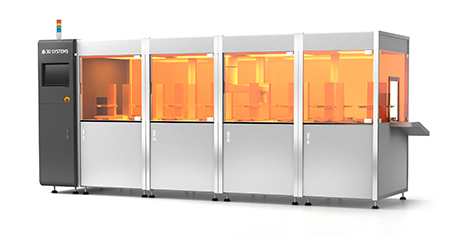

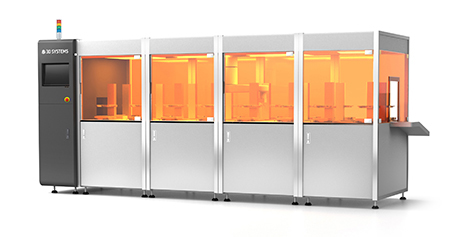

Figure 4 is a fully automated, high-volume 16-print engine production solution

3D Systems has announced Figure 4, which it claims is the industry’s first modular, scalable and fully-integrated additive manufacturing platform that is capable of producing plastic parts more than 50 times faster than current systems.

Based on its Figure 4 technology, the company’s new platform allows customers to tailor configurations and select materials to address specific applications.

Configurations can range from single-print engine machines to high-volume production systems with 16 or more print engines, automated material delivery and integrated post-processing.

“We believe our breakthrough Figure 4 platform will revolutionise manufacturing by transforming production of both mass customised and complex end use parts with a compelling total cost of operations versus conventional methods,” said Vyomesh Joshi (VJ), president and CEO, 3D Systems.

“While others are realising the need to transition from prototyping to production, we are delivering real solutions across all key vertical markets and applications that are helping customers solve problems today.”

Figure 4 platform combined with NextDent materials

As part of its vertical strategy that Joshi mentions above, 3D Systems has also unveiled one of its initial solutions for the dental industry based on the Figure 4 platform and its NextDent materials.

The company suggests that the new platform will be able to achieve improvements of up to 10 times in total cost of operations, along with significantly reduced fabrication times and far less material waste.

“Traditional milling machines only mill one crown at a time, making the process slow, ineffective and costly. Our system can print 20 – 30 crowns in fewer than 15 minutes, which is the same time it takes most milling solutions to produce just one single crown,” continues Joshi.

The system will be shipped later on this year and 3D Systems says that over time it intends to extend the Figure 4 platform application by application to meet specific customer needs across healthcare, aerospace, automotive and durable goods industries.