The world of 3D product development technology appears to be in a state of flux. Over the past two years the movements of many vendors, new and old, have seen a rebirth of interest in a field that many pundits considered to be mature, tired and almost squeezed dry of innovation. If the twenty-year ‘overnight’ success of direct modelling/direct editing has done one thing, it’s made 3D CAD interesting again.

While there are many reasons that this has happened (advances in solid modelling algorithms and CPUs), it got kick started by the new kid on the block, SpaceClaim. Two years ago the company appeared out of nowhere and showed off its eponymous entitled SpaceClaim application. Much has been said about the product, which rather than relying on a construction history, adds intelligence to the model, regardless of the source.

Rather than focussing on what’s new with the 2009 release, I’m going to look at the system as a whole and where it fits into the crowded product development sector.

After a tumultuous two years, things have finally started to settle down in terms of how SpaceClaim is being positioned. It’s not being touted as a competitor to the mainstream product development systems, but rather something a little more leftfield, a product that does things that other typical history/ feature systems can not.

In terms of how this translates into a product, because SpaceClaim doesn’t rely on sketch-driven, feature-based history, it allows users to think much more clearly in 3D dimensions. You sketch a simple shape, pull it into 3D, then edit that geometry, directly, rather formalising your 2D sketch first.

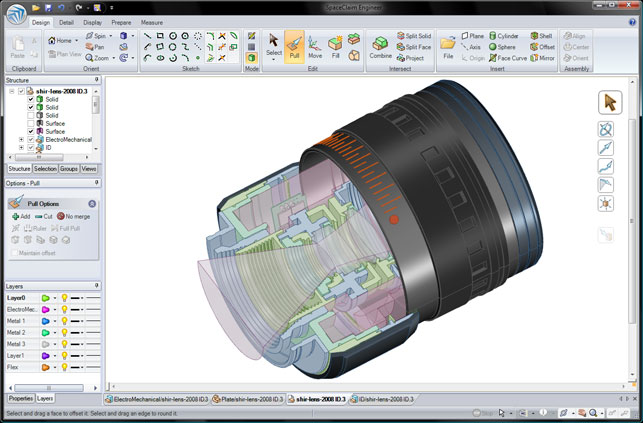

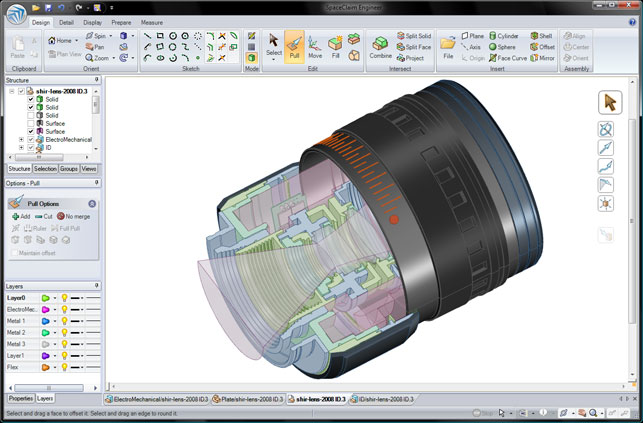

There are a number of tools that allow users to make quite dramatic changes to the form of the 3D model, either by editing it directly in 3D, or by using a temporary section through the model. Instead of all manner of 3D operations, the user has a couple of basics that are used eight times out of ten – Pull and Move. Pull will directly move geometry, points, edges, lines, and features, and maintain tangency and another other ‘inferred’ relationships where required. Move essentially shifts entities. While this is interesting and, compared to some systems, incredibly easy, where SpaceClaim excels is when it comes to editing geometry created in another system.

This shows one of the most interesting ways of working with 3D geometry in SpaceClaim. By working at a sketch or section level, and directly manipulating the geometry, users can maintain clarity of sight on what’s going on and the effects of edits, while maintaining the 3D geometry at the same time. This makes working with certain products, such as this lens, much easier

Data translation

The system has a range of translators that cover pretty much every system on the market today. At the base level it supports ACIS, STEP, IGES, Rhinoceros, CGR (from Catia), DWG, DXF, STL, OBJ, XAML, VRML, and 3D PDF (assuming you have Acrobat 9 Pro Extended). There are several additional data translation modules, one of which adds Pro/Engineer, Inventor, Catia V4, and VDA, another for SolidWorks, NX, and Parasolid, another for JT and, finally one more for Catia V5. The system can also read in the main ECAD file formats and use that data to construct a 3D model of a PCB board from both PDF and EMN files (N.B. this is not included in SpaceClaim Style – more on this later).

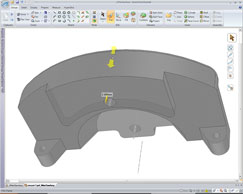

Here, a cast component is taken and the features removed for downstream processes, such as CAM or FEA. Machining stock can be very quickly added to the part, which is particularly useful when the machine shop might not have access to the native geometry

Fixing Geometry

These days, while most systems are able to output pretty solid geometry, there are still some that’ll throw out a few clunkers. With the 2009 release, SpaceClaim has a new set of tools collected under the ‘Prepare’ tab, specifically for working with geometry. The first fixes common problems in solid geometry: gaps, missing faces, split edges and inexact edges. The system highlights problem areas and helps step the user through them to create a valid model. Progress is highlighted by a colour and display style change, as well as an icon appearing in the structure panel. Most minor problems can be fixed with this tool, but if there are bigger gaps, which require complex, manual work, then more advanced tools for merging faces, closing tangency, filling gaps are also available.

Preparing downstream data

The other purpose of the ‘Prepare’ tab is to provide tools with which to prepare models for downstream purposes and this is something that SpaceClaim is highly suited to in general. The two examples that spring to mind are CAM and FEA (Finite Element Analysis). FEA, for example, requires a process called abstraction, which strips out all of the extraneous detail to give a much more efficient model to mesh. This means stripping out fillets/chamfers, small features and holes. SpaceClaim has specific tools to remove chamfers and fillets/rounds, faces and to find interference. There are also more manual tools to dive in and work on more problematic areas. The good thing is that the tools are easy to use and don’t particularly rely on the sometimes arcane language of 3D CAD. Want to fill a hole? Click fill. The user doesn’t need to decide how; the system makes all the decisions. Also, on the simulation side of things, the new volume extract tool will make mincemeat of creating fluid flow volumes for CFD runs.

SpaceClaim provides a toolset that can get users out of some of the sticky situations they may find themselves in

Core design

But what about core design work? What can the system do? When looking to tweak geometry, move the odd feature slightly, or to add or remove fillets, simple pull or move operations are sufficient in many cases. However, when things get complex there are also a variety of tools to handle more manual jobs, such as reconstructing geometry from scratch or adding new features. There are also a range of sketching tools that enable users to make pretty dramatic changes to a 3D model and work it into different shapes. This is perhaps one of the best things about SpaceClaim.

With current economic pressures, most smart organisations are looking to change how things are done, and how they can squeeze more from their products. One way to do that is to redesign existing products, using new material selections. For example, whereas once an aluminium casting was used, it’s now been replaced by plastic. This is something that crops up in the medical sector in particular, or indeed any other field that relies on high-cost, low availability products. SpaceClaim is ideal for this type of redesign work. Most products iterate, rather than being built from scratch and using the direct edit tools a product designed for one manufacturing process can easily be adapted to suit another, while ensuring that the form and function requirements are met. The reason this is so easy is by removing the need to edit the history tree, the user can immediately dive in, and push, pull and edit geometry into shape.

SpaceClaim products

There are two versions of the software: SpaceClaim Engineer, which is the all-singing, all dancing version, then SpaceClaim Style, which provides all the 3D modelling tools, but without the ECAD, mechanical detailing, sheetmetal, and model cleanup tools. While the Style version costs £895, the higher-end version costs just £1,995, which is still not a great deal in anyone’s books. There are also a number of product bundles available, such as the link with Rhino or HyperShot, which mean that users can mix and match some best in class tools and create a workable process to take a product from conceptualisation, through the engineering (which SpaceClaim handles) and pop it out the other side.

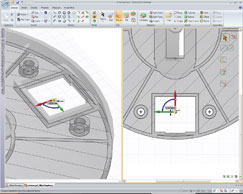

In a history-based system to dive in and move the two mounting features in this cast component would require editing a sketch and rebuilding that geometry. In SpaceClaim you simply select the geometry and move it. The end result (pictured right) merges nicely with the thin wall of the component

Conclusion

I haven’t got a huge amount of column inches to cover all of what SpaceClaim does and how, but you should get a feeling for the flexibility that’s on offer here.

There’s a huge debate raging in many quarters about how the new breed of direct editing tools stack up against the traditional parametric- and history-based systems. However, to my mind, this seems almost redundant. The fact is that the different approaches suit different workflows and projects and for some organisations it might even mean a mix of the two. The good news is that SpaceClaim is pretty affordable so it can easily be used in parallel with other systems.

I’ve been talking to some users that have acquired SpaceClaim in the last few years and if there’s something that connects them all, it’s the simple fact that the application is very easy to use, and allows them to get their ideas into a digital format in a very short space of time. The system isn’t likely to go head to head with the likes of SolidWorks, Solid Edge and Inventor, even if they are starting to feature similar modelling concepts (Solid Edge is perhaps the closest, but Synchronous Technology is a different kettle of fish entirely). What SpaceClaim can do though is sit alongside these tools and provide a toolset that can get users out of some of the sticky situations they may find themselves in.

It’s an impressive system and, now in its fourth major release, is maturing having solved some of the early teething problems. With this in mind it has all the ingredients to find itself a niche in the 3D design tool market.

SpaceClaim’s user Interface

As you’d expect from a system as new as this, the SpaceClaim user interface is all about Microsoft’s Ribbon. Commands are presented in logical groups and those groups are defined by task, rather than functionality. There’s Design (for geometry creation and editing), Details (for drawing), Display (for display control, layer management etc), Prepare (a new tab for preparing and processing imported geometry), Measure (for review and mark-up) and HyperShot, which contains a single icon that links to Bunkspeed rendering system if you have it installed.

Down the left hand side, you have a number of panels. There’s the usual part browser, which as you’ll probably be aware, is one of the selling points of SpaceClaim in that it does not rely on a construction history. Instead the system adds the intelligence to the model, no matter what the source. You also have layer and selection control and standard display views. The majority of the interface is given over to the model window and considering the very direct and interactive nature of SpaceClaim, this is a huge benefit.

| Product | SpaceClaim 2009 |

|---|---|

| Company name | Spaceclaim |

| Price | from £895 |