At Siemens Realize Live in Amsterdam, attendees got to hear how the company is focusing on integration and innovation to deliver a single digital thread for manufacturing and product development, as Martyn Day reports

You know you’re at a Siemens event when the speaker roster includes some of the global manufacturing sector’s biggest names. At the company’s recent Realize Live event, which ran for three days in Amsterdam between 30 June and 2 July, over 1,800 attendees had the opportunity to watch presentations by representatives of Airbus, Unilever, GE Aerospace, Rolls-Royce and Scania, among others.

These are challenging times for such companies. Global trade turbulence triggered by the Trump administration’s sweeping programme of tariffs is focusing manufacturing-sector minds on where raw materials are sourced, how products are made, and where they are sold. Software from Siemens, in areas such as CAD, PLM and smart factory automation, plays an increasingly important role in how companies make such decisions – but the times are challenging for Siemens, too, as the volatile trading environment leads to extended sales cycles and delayed technology investment decisions among customers.

Still, Siemens Digital Industries Software has a strategy for weathering the storm, based on three pillars, and these were outlined at the event by chief revenue officer Robert Jones.

The first pillar, said Jones, focuses on providing “the world’s most comprehensive digital twin”, which delivers a complete virtual representation of products and processes.

The second pillar is one that Jones referred to as ‘Adaptive Operations’, and which aims to integrate the physical and digital in manufacturing, using software-defined automation and, in Jones’s words, “bringing the industrial edge into the software world.”

Finally, the third pillar is ‘Lifecycle Intelligence’, which involves leveraging data and AI within Teamcenter to create an “adaptable AI backbone” that delivers deeper insights throughout a product’s lifecycle. According to Jones, this vision is driving the company’s investment strategy, and ultimately, Siemens’ portfolio must deliver this breadth of functionality, with best-in-class applications delivered as an integrated solution on a ‘digital thread’ backbone. The company’s commitment here is evidenced by its acquisitions of Altair (simulation), Dotmatics (life sciences), Downstream Technologies (PCB verification) and Wevolver (supply chain resilience).

Payoff Time

At Siemens Realize LIVE in Amsterdam, I got the distinct impression that the company’s decades-long programme of internal development, acquisitions and planning is starting to pay off for the company, giving it several advantages over competitors. In terms of digital thread technology, for example, Siemens now has a product suite in which constituent parts all speak the same design language. NX, which is managed through Teamcenter PLM from initial concept to analysis and fabrication, not only covers mechanical components but also software, electrical and even chip design. In other words, it spans the desktop and the cloud, individual work and team collaboration, and all areas up and down the supply chain.

That stands in contrast to Dassault Systèmes, which still has a disconnect between Solidworks Parasolid and Catia CGM. At Autodesk, it’s between Fusion and Inventor. At PTC, it’s between Onshape and Creo.

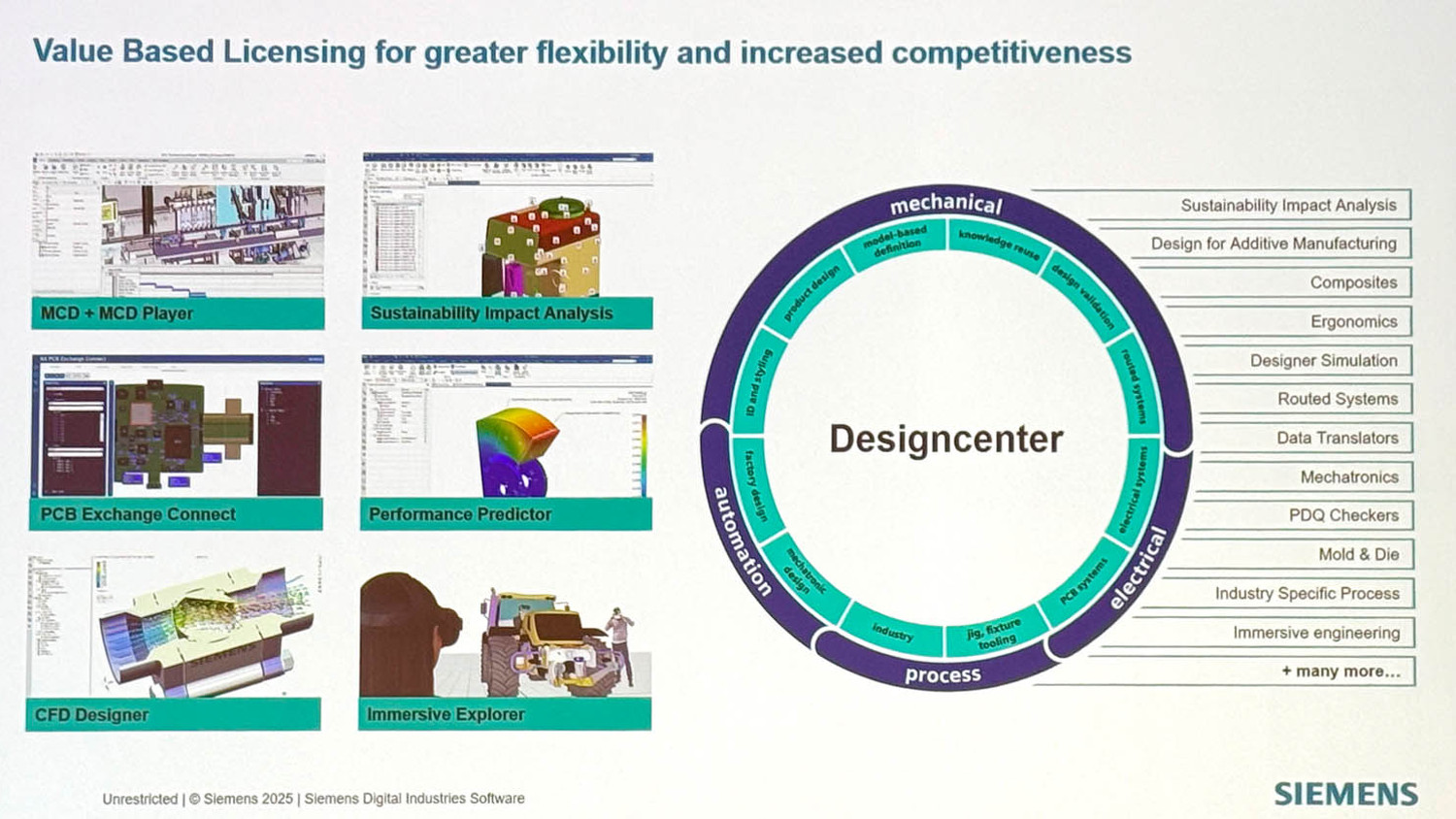

By contrast, Siemens executives were heavily selling the company’s new product engineering suite – Designcenter – which was launched earlier this year (www.tinyurl.com/designcenter-D3D). This acts as a strategic umbrella for all the company’s product engineering solutions. NX, It has already consolidated NX and NX X under Designcenter, and will continue to add solutions under that brand, including a new cloud-based tool called NX X Essentials.

Siemens executives explained that Solid Edge is a key product within Designcenter, a lot of work has been dedicated to enabling the combination of NX and Solid Edge in design teams to work together as one.

The Solid Edge and NX product names will continue to be used, and the products won’t be rebranded or replaced. Instead, they will be integrated under the new Designcenter umbrella. As part of this there will be 4 NX X tiers: Essentials, Standard, Advanced, and Premium versions.

Solid Edge and NX previously functioned as technically different product stacks, but they both use the same Siemens tool components, including Parasolid, DQ and JT. It looks like Solid Edge in Designcenter will see changes over time to increase the interoperability and alignment with NX, in terms of data, user personas and the digital thread flow across the entire product stack.

Minor changes have already been made to the Solid Edge UI, to align colours, look and feel. Parts and assemblies can be exchanged between NX and Solid Edge with no issues and, for Solid Edge customers, drawings can be moved from Solid Edge to NX using an interoperability manager.

The AI-enabled co-pilot technology, available in NX, is released as the same co-pilot in Solid Edge, sharing code and leveraging capabilities between the historical teams.

In many ways, this is the same amazing engineering feat that Siemens pulled off developing both SDRC Ideas and Unigraphics to eventually become NX over many years. Unifying NX and Solid Edge is an easier prospect, as the products already share so many core software components.

Siemens’ Zel X product, a cloud-based 3D model viewing tool that supports 2D drawings, sketching, history-part based modelling and project sharing, has been rebranded NX X Essentials.

Desktop and Cloud

When it comes to the interplay between desktop and cloud environments, product updates are now applied to both NX and NX X. Siemens positions NX and NX X, which features cloud-based integrated product lifecycle management, as part of its broader Siemens Xcelerator portfolio. This indicates that while the core functionalities reside within the NX software, the strategic direction embraces and supports integrated cloud workflows through NX X. The 2025 release of Solid Edge last year also included the launch of Solid Edge X, which also provides cloud-workflows for that product.

Recent updates to NX and NX X, which encompass advancements such as the AI-driven Design Copilot NX, immersive engineering capabilities including NX Immersive Designer and NX Immersive Collaborator, and enhanced Design for Manufacturing (DFM) tools like NX Inspector and DFM Advisor, are all delivered as part of this broader Designcenter suite.

Additionally, integrated designer-focused simulation tools, such as NX CFD Designer software, are also aligned with this consolidation. This framework signifies Siemens’ ongoing commitment to integrating and evolving its product engineering toolset.

For design for manufacturing (DFM), Siemens has introduced several enhancements such as NX Inspector, which is a new capability that extends model-based design (MBD) by adding model-based characteristics to a digital twin. This aims to streamline downstream quality and manufacturing processes based on industry standards.

The DFM Advisor automates early manufacturability assessments by analysing part geometry and identifying potential challenges across various manufacturing processes like drilling and milling, and providing actionable feedback. Furthermore, the NX Mold wizard has been enhanced with intelligent standard parts and improved cooling channel simulation tools.

Integrated designer-focused simulation tools are now available directly within the CAD workspace. NX CFD Designer software, powered by Simcenter FLOEFD technology, provides fluid flow and thermal simulation capabilities. It is designed for ease of use, automating complex tasks like fluid volume detection.

The capabilities of Performance Predictor have also been extended to enable mechanical stress analyses across entire assemblies.

Uncertain Times

In uncertain times, investments in flexible engineering management tools have the potential to pay for themselves many times over. At Siemens Realize Live, there was lots of great tech on display.

NX goes from strength to strength. Siemens is succeeding in both acquiring and integrating a vast portfolio of products, getting them to work together and introducing to the mix advanced technologies such as AI, XR and simulation. So far, we are only just scratching the surface when it comes to understanding where all this is going.

Another product that caught my eye at Realize Live was Mendix, a low-code environment for developing new applications, acquired by Siemens in 2018. This enables users to quickly develop and deploy enterprise-scale solutions via drag-and-drop components and the guidance of an AI co-pilot, meaning users don’t need extensive software development skills and experience to build apps that solve internal workflow issues.

The digital thread strategy, meanwhile, is resulting in Siemens winning some big deals, according to company executives, as well as enabling it to become more deeply entrenched within existing customers. Bob Jones highlighted as examples recent successes at BYD, Volvo and Bombardier. For a company that has never really focused on marketing, Siemens is exceptionally confident of its products and its vision.

If I have one complaint, it’s that branding and naming conventions are too complicated. It’s just hard to keep up. But my overall impression is of a company that is evolving and reorganising itself – and doing so publicly and in front of a global audience. Clarity is still a little lacking. I’ve been told that there is significant consolidation still to come when it comes to groups and branding. We shall see.

View on-demand content from Siemens Realize Live here.

Next year’s European event will run from 29 June to 1 July 2026. The US event will run earlier, between 1 and 4 June 2026.

BAC jumps to Siemens

Wandering around the Siemens Realize Live exhibition, I bumped into Ian Briggs of BAC (Briggs Automotive Company). He told me that a significant shift at BAC has seen the company move from Autodesk Fusion/ Inventor digital design tools set to software from Siemens Digital Industries Software, which it will use to develop its nextgeneration, single-seater, roadlegal supercar. More specifically, it has selected NX X CAD from Siemens’ Designcenter suite.

“The reason we chose Siemens’ Designcenter software to develop the next generation of Mono is because it’s the best – and it gives us the tools we need to take our vision to the next level,” Briggs told me.

Adopting Designcenter, he continued, will ensure compliance with global regulatory and safety standards:

“Understanding the specific positional requirements for everything from headlights to driver sight lines is a complex minefield. Designcenter’s advantage lies in its ability to build that entire regulatory framework directly into our 3D CAD model, giving us new levels of confidence and a greater speed of development.”

Briggs added that BAC is also exploring how Siemens’ immersive XR engineering technology might be used to enhance the customer buying and customisation experience.

This technology enables them to visualise and interact with bespoke vehicles, utilising real-world 3D CAD data in high-fidelity realism. In this way, customers can sit in a seat fitting jig and see all of the customisations they want around them, as if they were already implemented in their custom car.