Cognitive Design Systems (CDS) has released Cognitive Design 2.0, the latest version of its AI-powered engineering platform, featuring Design Explorer capability for where performance and efficiency define product success.

CDS says that advancements in the new release will enable engineers to unlock, test, and validate manufacturable high-performance designs at record speed – together, in one collaborative environment.

Cognitive Design 2.0 combines generative design and simulation for rapid exploration of structural part concepts with manufacturing process constraints for 3D printing, casting, machining, moulding and forging.

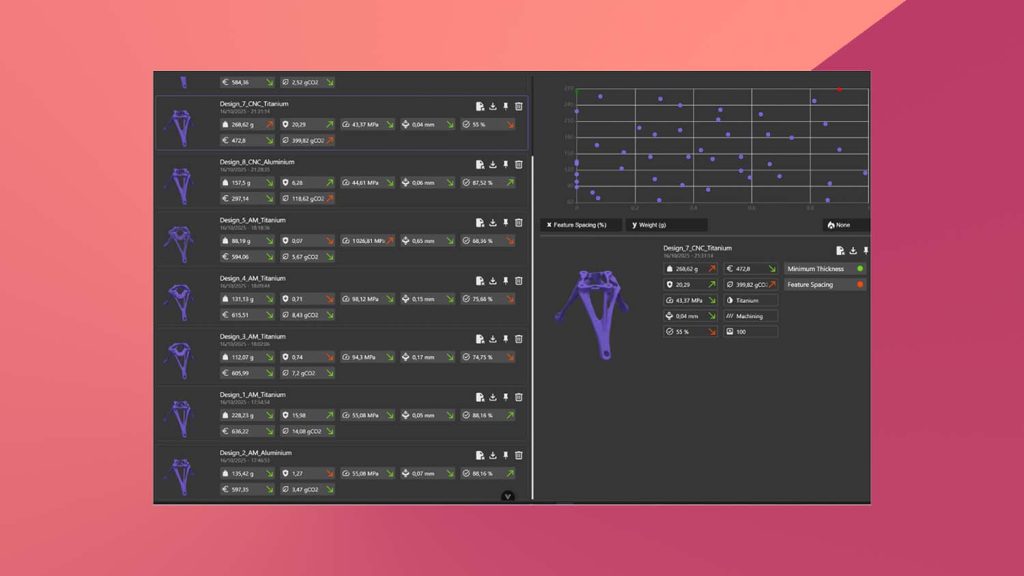

Data-driven decision-making, guided by a unified dashboard that compares design iterations across performance, cost, weight, CO₂ emissions and manufacturability KPIs also help guide designs.

The clearest example of this is in the new Design Explorer capability that provides a multi-criteria comparative view that then centralises all design iterations, simulations and cost analyses in a single workspace. Users can now generate and explore high-performance design concepts faster, integrating performance and process constraints from the start.

“Cognitive Design 2.0 empowers organizations to turn Design Exploration into actionable insights, transforming every engineering workflow into a reusable asset” said CDS CEO Rhushik Matroja.

CDS has announced Thales Alenia Space as one of its beta testers for Cognitive Design 2.0 – explaining how it used it to translate engineering innovation into measurable program impact. Thales Alenia Space leveraged Design Explorer and reusable, simulation-driven workflows to automate the design of an entire family of antenna reflector tripod supports.

By embedding manufacturing constraints from the start across AM, Casting, Machining, Molding, and Forging, the teams claim to have achieved up to 50 per cent shorter engineering lead times and 30 per cent mass reduction per bracket, while maintaining full compliance with mechanical requirements.