Carbon has announced that all its 3D printing system subscribers have been given access to its Design Engine software, with the lattice software eventually being made available to everyone.

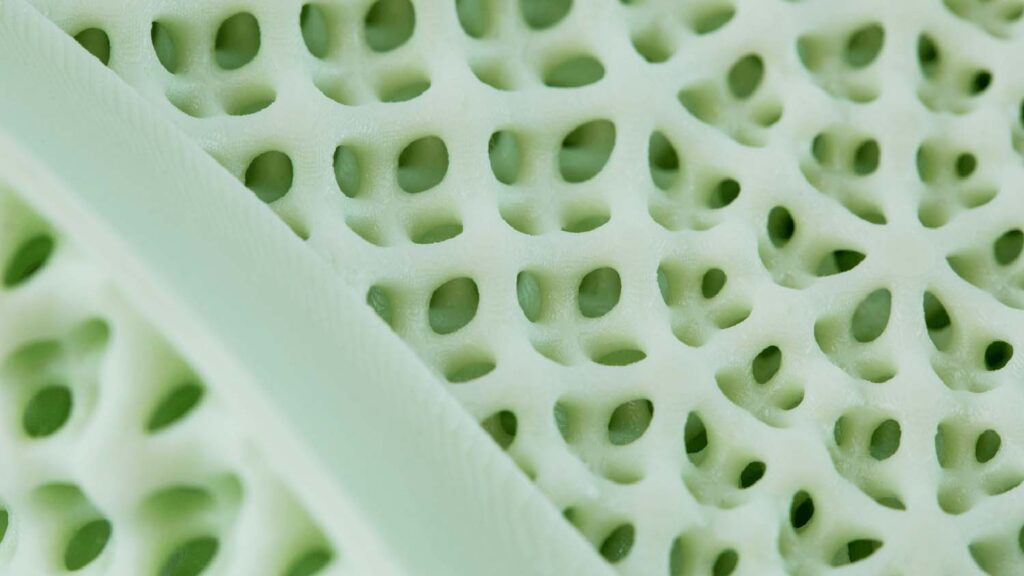

Design Engine helps to automate the process of creating performance-oriented lattices, saving design engineers significant time and effort.

“It’s a design tool used by anybody… whether it’s DLS or not,” said Carbon CPO and BDO Phil DeSimone.

“It’s ready for prime time – it’s meant to help people understand how to design for lattice… the bigger opportunity is for the industry as a whole.”

The software has been proven in production with the design of lattice products like the Specialized S-Works Power Saddle, and CCM Super Tacks X helmets.

DeSimone explained that Carbon Design Engine has already been used to create parts produced in metals and other polymers outside of the Carbon ecosystem already, and the plan is to gradually release further features on top of the initial lattice-based design software.

No timescale has been set for a wider availability, although it is expected that Carbon’s global partners will be some of the first to liaise with existing clients about trialling it.

Carbon Design Engine is a cloud-based application, which provides the computational power to generate complex shapes quickly and efficiently without requiring local resources.

Design Engine software has a fully interactive user interface and offers product teams the ability to produce five different types of conformal lattices – creating conformal lattices that can populate challenging design surfaces, eliminating tedious design revisions post-generation.

“With the release of Design Engine to all Carbon subscribers, we are helping designers iterate through their design thinking, faster,” said DeSimone.

“On average it can take 18 – 24 months to bring a consumer product to market. But when we put the best design tools, 3D printers and materials in the hands of designers and manufacturers, we enable the development of advanced components and products – going from idea to production in the same day.”