Ready for some browser-based 3D modelling and collaboration fun? Onshape is… Are you?

Today, perhaps one of the most talked about (usually in hushed tones) software companies in the design and engineering space, is finally going public with it’s offering to the market.

Founded by many of the original SolidWorks team, Onshape, is finally putting its eponymously named design tool into a public beta.

If you’ve missed the rumblings in the last two years, here’s a quick catch up.

Originally founded as Belmont Technology, Onshape is headed up by Jon Hirschtick and staffed by a mix of the original SolidWorks development and business strategy folks that eventually sold out to Dassault Systemes back in 1997.

Since news started to emerge that “the band was getting back together”, the 3D CAD world has been talking about what the company might or might not do.

One thing has been certain, with $64 million in investment capital in its coffers and a killer team, something interesting was brewing.

Early last year, much of that plan started to emerge, under a strict NDA which lifts today. While we’ll be getting into a much deeper look into what the tool can and can’t do later on this week, it’s worth a quick overview.

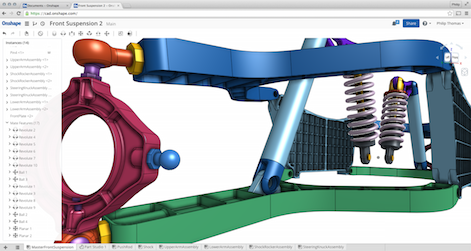

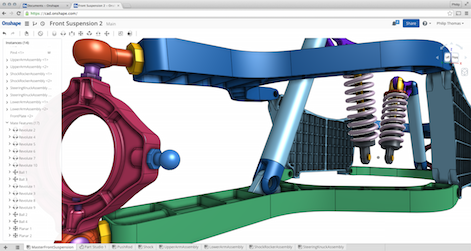

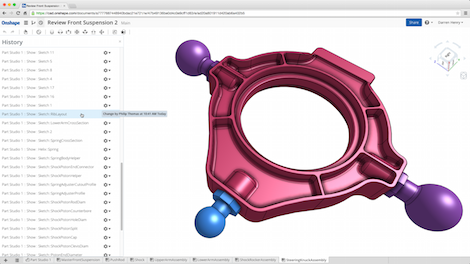

Onshape (the product, not the company) is a cloud-based affair – after all, this is the new hot-shit in software circles and represents where things are heading. Technically, Onshape is comprised of two key areas, 3D design/engineering and the data management and collaboration backbone it works within. The two are tightly interrelated.

The front end, in terms of design creation and editing, is a cloud-based, browser only 3D CAD system. Once you’ve signed up for the beta, you log-in and it’s there, ready to use. You’ll need a WebGL compatible browser, namely, Chrome, Safari or whatever you fancy.

No heavy weight graphics cards, not massively powerful workstation. As long as it meets the browser specs, it should work. No download, no client stream, no install. Log-in. Go.

In terms of modelling tools, Onshape, in its present guise, is light. This is a system that’s been in development for a couple of years, but much of that work has concentrated on the development of the platform, rather than the individual feature set.

You’ve got the basic solid and surface modelling tools you’d expect – extrudes, revolves, sweeps, shells (and thickening), rounds/chamfers, mirroring (of bodies, rather than features), patterns and of course, Boolean operations. There’s also a selection of direct editing, but nowhere near what you might expect these days.

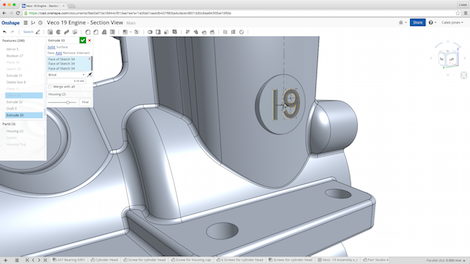

Onshape’s modelling tools are split into two ‘studios’ Parts and Assemblies. The idea is that you do all of your part modelling using a multi-body approach.

The feature history is tracked (in a panel down the left hand side) in a linear manner. It’s not split out per part or body – it’s a single monolith.

Parts are defined on the fly, can be combined with each other whenever you need and all of your current parts are in the panel below the feature history listing.

In terms of interaction, things to take note of are: right-hand mouse button is context sensitive and holds a lot of the common features and functions (hide, show, etc.), as well as short cuts to edits. The middle mouse button is pan, the right rotate. At the top right of the modelling window you have the view cube and display settings.

When it comes to assemblies, while you can build in interaction or mating references into parts, you can do the real work in the Assembly Studio (these are accessed in the strip of tabs at the bottom of the screen).

Graphical glyphs are placed (to give position) and then given functions for how they interact.

What’s interesting is how all of this works inside the browser. Onshape doesn’t do any work locally. Everything is connected and calculated by the cloud-servers.

When you interacti with the geometry, be it sketch or solid, surface or fillet, what you’re doing is communicating that intent to the server, it calculates the result and feeds it back – in real time.

You’re driving Onshape ‘remotely’. We’ll get onto what that means shortly.

Data centralisation, management and collaboration

The other key component is the platform onto which these tools are built. Because of its cloud-based nature, Onshape has data management and collaboration built in.

All of the data you create and upload is stored centrally. It will track versions (you have to create those version manually) it supports branching and merging.

This allows you to split a design path to explore options, then bring together those results into a single track again.

Of course, collaboration is easy. After all, one of the key benefits of having all your data stored centrally is that it’s easier to share. Hit the Share button and you’re away.

With Onshape’s browser based technology, the other party also has access to those tools as well (remember that bit, it’s key we’ll explore why shortly).

Cloud means connection

By now, you should have picked up on the cloud-based nature of this thing. This is fundamental to the whole effort. But it does have its pitfalls.

At present, Onshape works with a live connection. Whereas Autodesk’s Fusion technology uses, for the most part, a synchronised approach, where you download, edit locally, re-upload your data using a local client, Onshape differs. If you don’t have a web connection (and it’ll run on a 4G connection), you don’t have access to any of the tools.

That means on a train, in an airplane, in some of the more remote locations, on-site where it’s not permitted, you don’t have access to your design data or the tools you need to work with it. Personally speaking, I spend a lot of time out and about and we know that designers and engineers are exactly the same.

Do you always have a reliable web connection? Probably not. If there’s an achilles heal to Onshape, at present, then this is it, in my opinion.

How different is it this time around?

Let’s consider the environment that SolidWorks launched into. SolidWorks was launch in 1995. Let’s give them two years to get set-up and running and put a stake in the sand in 1997. The dominant and hot ticket software in 1997/1998 was Pro/Engineer from PTC.

When it was launched in 1987, it brought a different approach, parametric modelling, that changed how things could be accomplished, how intelligence could be built into a 3D product model’s geometry. It also broke up the recipe that described the construction of that model into a series of features.

Now. Consider what SolidWorks offered. SolidWorks, at a technical level, did very little that was new or novel when it hit the market. Its approach to features + history + parametric was, essentially, a clone of Pro/Engineer. The old 80/20 rule applied. 80% of the functionality at 20% of the price.

What SolidWorks did, however, that was new and innovative, was to dramatically lower the cost. Pro/Engineer at this time required some serious hardware and the software was similarly costly. You wouldn’t have got much change out of 25,000 to 30,000 per seat.

SolidWorks was delivered on the Windows platform, with lower cost hardware and cut that by two-thirds (as a rough estimate).

It also had a sales channel that was like no other. In many cases, built up by veterans of imploding other vendors or resellers of their systems, SolidWorks attracted a different bunch.

Yes, eager, yes, hungry for success, but without some of the peculiarities (read: aggressive and confrontational) that characterised PTC’s sales approach at the time).

What SolidWorks was, if you boil it down, was a cheaper alternative (both in terms of hardware and software and on-going maintenance) to Pro/Engineer sold by nice people that had some serious boots on the streets and selling to all those customers that they missed the first time around.

So, does that sound familiar?

Onshape looks to be attempting something very similar, using the cloud (the equivalent of the move from UNIX boxes to Windows) as the platform shift.

By doing that, it’s removing the need for expensive computation (it’ll work as well on your iPad as well as it does on a standard-ish laptop or workstation) and cost.

What I also realised is this: The environment in which they’re trying to do this is dramatically different.

In 1997, when SolidWorks started to ramp up, PTC was shipping around 7,500 seats per quarter with a total user base of around 100,000 by the end of the year. Consider that fact. After 10 years, the company had sold, on average, 10,000 seats a year.

Now consider the environment today. SolidWorks has, at the best estimates, half a million+ commercial customers. Autodesk Inventor has similar. Then there’s Solid Edge and all the other 3D design and engineering systems out there. This is fundamental to my point.

When SolidWorks took off it did so in an environment where the vast majority of users had never seen, never mind used, a parametric 3D modelling system. If they had seen one (remember, the internet was by no means widespread), they probably couldn’t afford it: AutoCAD, ME10 and the drawing board reigned supreme.

If they had enquired, they ended up with PTC’s sales guys on their doorstep, probably going over their heads, when they said they couldn’t afford it or didn’t need it. So they were stuck. They realised that AutoCAD or their drawing boards’ weren’t going to cut it in the future. But they couldn’t afford it.

Then along comes SolidWorks and its friendly channel. It does much the same thing as Pro/Engineer, is on an aggressive development curve and sold by the ‘good guys’.

No wonder that it took off and grew massively. PTC got distracted with the Computervision acquisition and missed the PC revolution and SolidWorks’ channel sneaking up behind them.

Yet today there are literally millions of seats of highly advanced, highly capable, 3D CAD softwares out there being used daily where they have been for nearly 20 years.

When SolidWorks launched it could get away with not matching Pro/Engineer in terms of functionality because of a) the lower cost and b) the simple fact that very few of their potential customers had even seen such technology before, never mind actually used it.

New Game – New Rules

Today’s designers and engineers have decades of collective experience with these tools. They’re also highly connected.

In 1997, the only way to see a system like this was to go to a trade show, send off for a CD or book a demo. That clearly isn’t the case any more. At the tap of a few keys, you can sit and learn everything you need to about a system in a matter of minutes.

Now bear in mind how ‘shareable’ Onshape is. Now that the beta is in place, anyone that signs up for it (and you get five free projects to work on before you need to start paying – it’s $100 a month or $1,200 per annum) can immediately share it with someone else.

Someone on their team, someone that works for a customer, a supplier, a client, a friend. that’s incredibly powerful. As soon as they accept that share, they’re in the tool. They’re not scrabblingg around for a viewer or to import the data into their own 3D design tools (if they have them). All of Onshape’s tools are right there, to play with. That is incredibly powerful.

At the moment, Onshape’s capability is limited, but still there are products on the market now that have been designed, tested, iterated and put into production using OnShape (I’ve visited a few of these customers already).

The richness of the tools will improve and, I suspect, improve rapidly. Drawings will come, greater modelling capability (I’m surprised there’s no Sub-D implementation at launch) will come. But most importantly, the infrastructure on which to build those tools is in place.

Now it’s a case of pushing adoption, gaining customer feedback (and they’ve been doing this for a year already) and building it out into a fully fledged product.

Yes, I do think they’re ignoring the off-line working too adamantly at the moment. high-speed internet is available, but it’s not ubiquitous. Our own research shows that designers and engineers are spending more time out of the office, away from their desks, than ever before. And that having a reliable internet connection isn’t always possible.

The 3D CAD world is still an important one and other than Autodesk and its Fusion initiative, there’s been very little new or exciting for a while (Dassault has its next generation products, but we’ve not come across these in the wild yet and some are doubting whether they’re actually even on the market yet).

And we all like something new and exciting.

Ultimately, however, there’s work to be done and the success of a company and its products in this space comes down to folks adopting those tools, cracking on and bringing new products to market.

We’ll be exploring Onshape in more depth in the coming months, seeing where it lies in the market and what can be achieved – as well as talking to the team about its plans.

You can also see it live with the Onshape team at DEVELOP3D Live later this month.

And of course, as of just about now, you can sign up for the beta and try it for yourself. If you do, drop us a line and let us know what your first impressions are.

We’re curious to find out.

Further reading:

Adam O’Hern at SolidSmack – “I can’t stress enough what a big deal this is. Forget about features, workflow, and the normal bla bla bla about cloud, collaboration, multi-CAD compatibility, etc. It’s all about The Benjamins. Even if Onshape itself turns out to be a dud (it won’t), mark my words: the game has changed.”

Carl Bass, CEO at Autodesk – Setting the record straight – “In light of their upcoming launch, several people have asked me about Onshape. Given how hyperbolic and misleading their statements have been, it is time to set the record straight. After all, Onshape is entitled to their own opinions – but not their own facts.”