If 2023 was the year that Autodesk announced its ambitions for AI, 2024 was when it fleshed out some of the details. But, as Greg Corke reports, there’s still a long journey ahead

The Autodesk AI brand debuted in Las Vegas last year at Autodesk University, but the launch lacked any real substance. Despite a flashy logo there were no significant new AI capabilities to back it up. The event seemed more like a signal of Autodesk’s intent to add greater focus on AI in the future — building on its past achievements. It came at a time where ‘AI-anything’ was increasing share valuations of listed companies.

Fast forward 12 months and at Autodesk University 2024 in San Diego the company delivered more clarity on its evolving AI strategy — on stage and behind the scenes in press briefings. Autodesk also introduced a sprinkling of new AI features with many focused on modelling productivity, signalling that progress is being made. However, most of these were for manufacturing with little to excite customers in Architecture, Engineering and Construction (AEC).

In his keynote CEO Andrew Anagnost took a cautious tone, warning that it’s still early days for AI despite the growing hype from the broader tech industry.

Anagnost set the scene for the future. “We’re looking at how you work. We’re finding the bottlenecks. We’re getting the right data flowing to the right places, so that you can see past the hype to where there’s hope, so that you can see productivity rather than promises, so that you can see AI that solves the practical, the simple, and dare I even say, the boring things that get in your way and hold back you and your team’s productivity.”

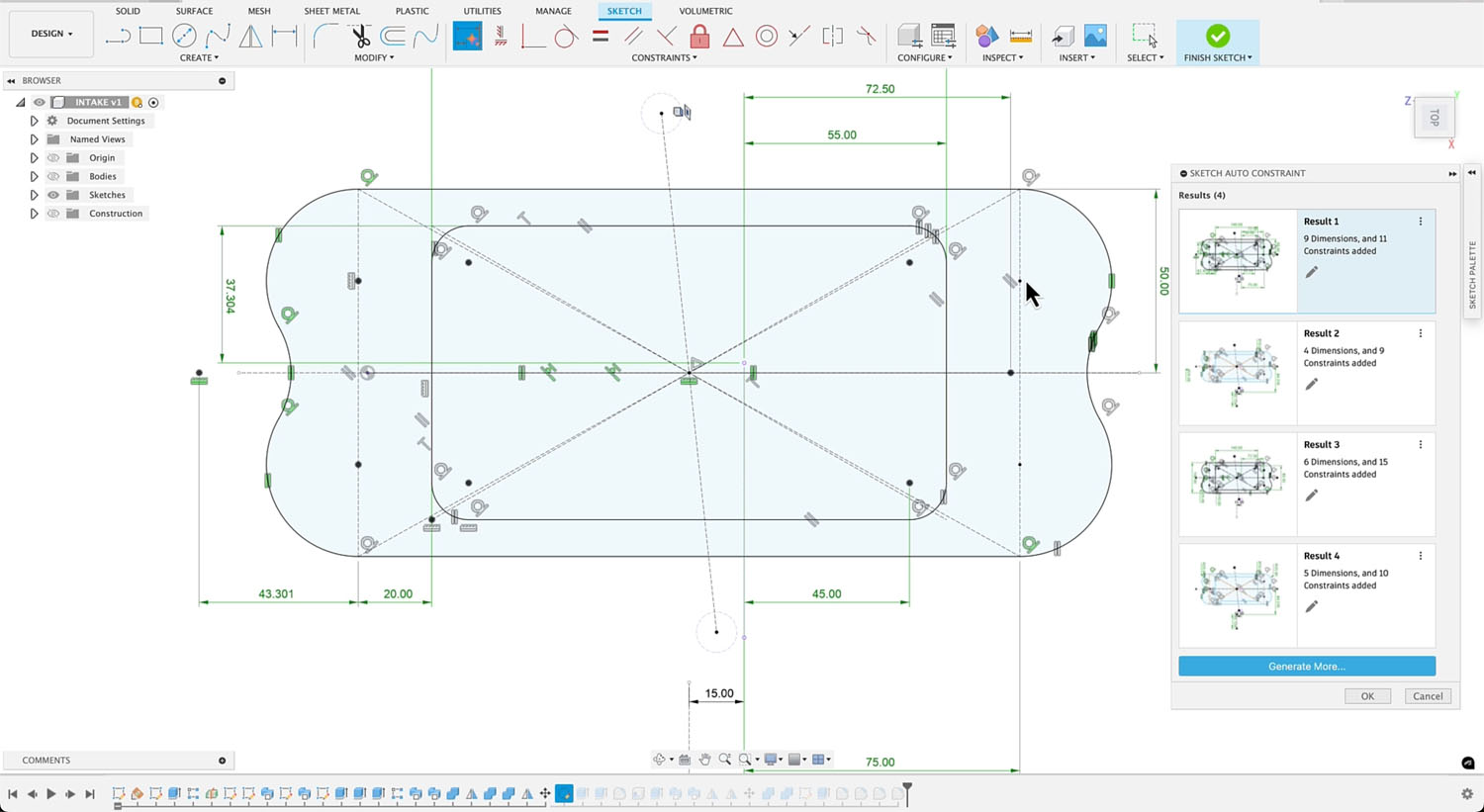

One of those ‘boring things’ is sketch constraints, which are an essential part of 3D modelling and govern a sketch’s shape and geometric properties. As Stephen Hooper, Autodesk VP D&M product development, explained they are time-intensive to create and must be maintained as the design evolves. “As a result, this step is often skipped,” he said. “That leads to manual rework if you ever change the orientation or size or position of the sketch.”

Autodesk Fusion’s new AI-powered sketch auto-constrain feature streamlines this process. It analyses sketches to detect intended spatial relationships between aspects of a design, such as symmetry, relative scale, and relationships between parts. It will then suggest dimensional constraints to maintain design intent through the entire project.

This, said Hooper, eliminates the need for your designer or engineer to spend hours adding relationships to a sketch.

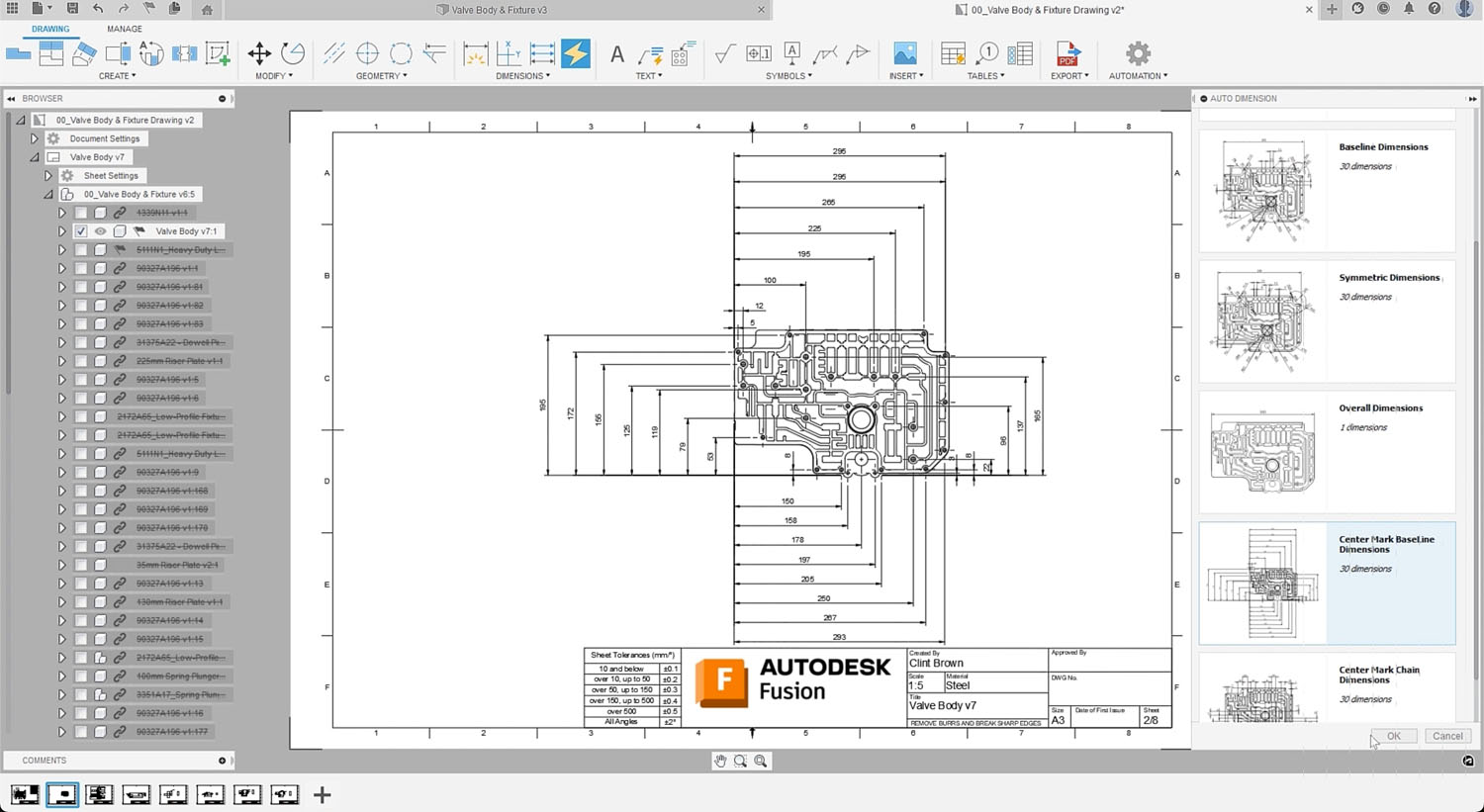

Automatically constraining sketches is just the starting point in Autodesk’s broader vision to use AI to optimise and automate 3D modelling workflows. As Anagnost indicated, the company is exploring how AI models can be taught to understand deeper elements of 3D models, including features, constraints, and joints. Another ‘boring’ task ripe for automation is the production of drawings. This labour-intensive process is currently a hot topic in CAD (read this AEC Magazine article). With Drawing Automation for Fusion, Autodesk is using AI to automate the process, down to the precise placement of annotations.

With the click of a button, the AI examines 3D models and does the time-consuming work of generating the 2D drawings and dimensions required to manufacture parts. The technology has evolved since its initial release earlier this year and now accelerates and streamlines this process even more by laying out drawing sheets for each component in a model and applying a style. Early next year, the technology will be able to recognise standard components like fasteners, remove them from drawing sets, and automatically add them to the bill of materials for purchase.

Both these new AI-powered features are designed to automate complex, repetitive, and error-prone processes, significantly reducing the time that skilled engineers spend on manual tasks.

This allows them to focus on more critical, high-value activities. But, as Anagnost explained, Autodesk is also using AI to fundamentally change the way people work.

One approach is to enhance the creative process. Form Explorer is a new generative AI tool for Autodesk Alias, designed to bridge the gap between 2D ideation and traditional 3D design. Emerging from Autodesk’s 2023 acquisition of BlankAI, it allows designers to ‘rapidly generate, modify, and explore 3D concepts in real-time’ without the need to manually edit complex 3D geometry.

As Hooper explained, the software accelerates creative development by leveraging a company’s historical designs to understand and apply its unique styling language. For each individual firm, the generative AI algorithm is trained on its past 3D models and their associated metadata.

Lessons learned from Form Explorer are also helping Autodesk augment and accelerate creativity in other areas of conceptual design.

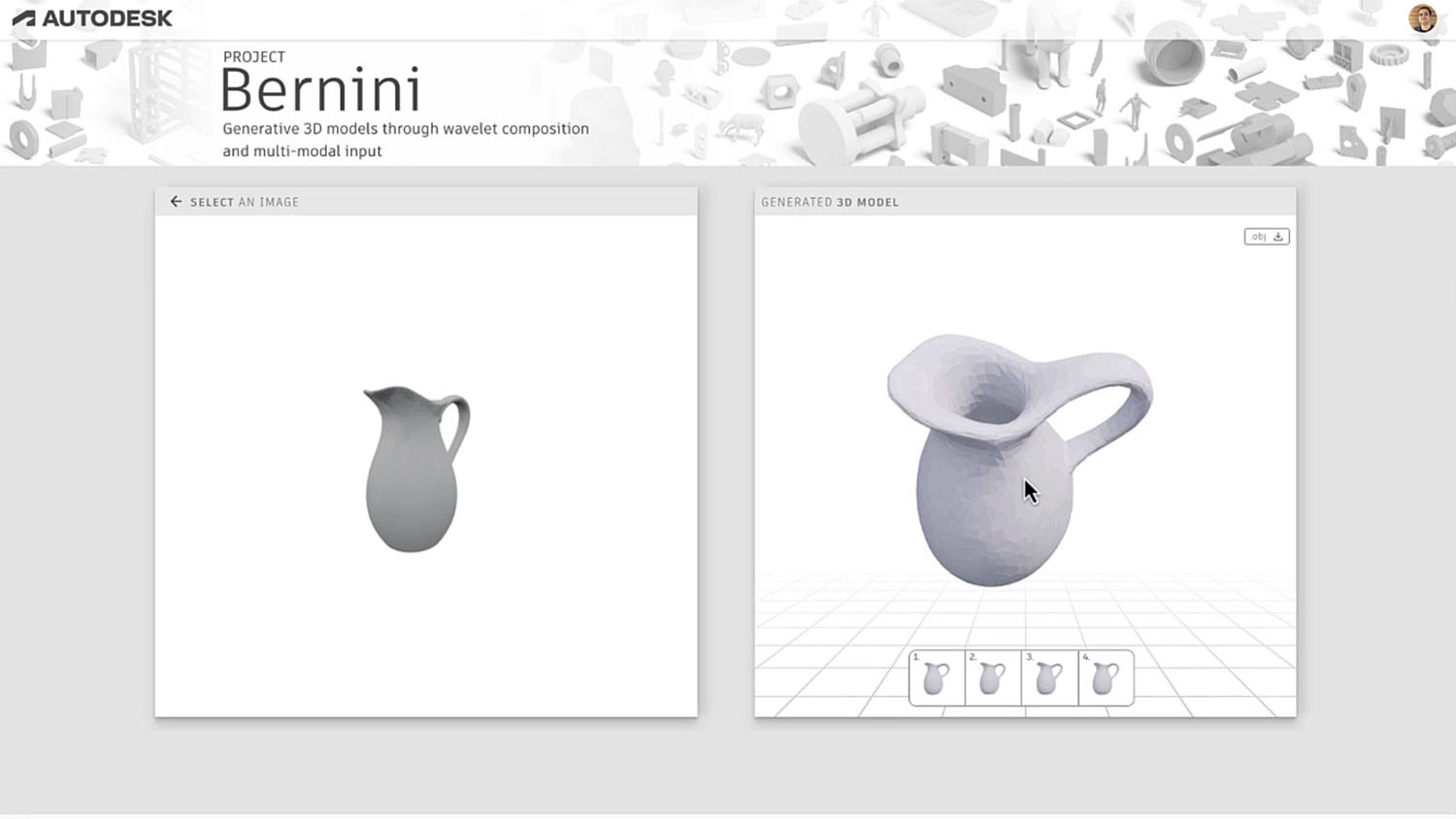

Project Bernini is an experimental proof-of-concept research project that uses generative AI to quickly generate 3D models from a variety of inputs including a single 2D image, multiple images showing different views of an object, point clouds, voxels, and text. The generated models are designed to be ‘functionally correct’, so a pitcher, for example, will be empty inside. As the emphasis is on the geometry, Bernini does not apply colours and textures to the model.

Project Bernini is not designed to replace manual 3D modelling. “Bernini is the thing that helps you get to that first stage really quickly,” said Mike Haley, senior VP of research at Autodesk. “Nobody likes the blank canvas.”

Project Bernini is industry agnostic and is being used to explore practical applications for manufacturing, AEC and media and entertainment. In manufacturing, one of the ultimate aims is to learn how to produce precise geometry that can be converted into editable geometry in Fusion. On stage at AU, Jeff Kinder, executive VP of product development and manufacturing solutions showed a prototype example of how the technology could be applied to conceptual design, taking a pair of sunglasses generated with Bernini into Fusion where the designer can continue to iterate on the concept.

However, there’s a long way to go before this is practically possible. There is currently no established workflow for this, plus Bernini has been trained on a limited set of licensed public data that cannot be used commercially.

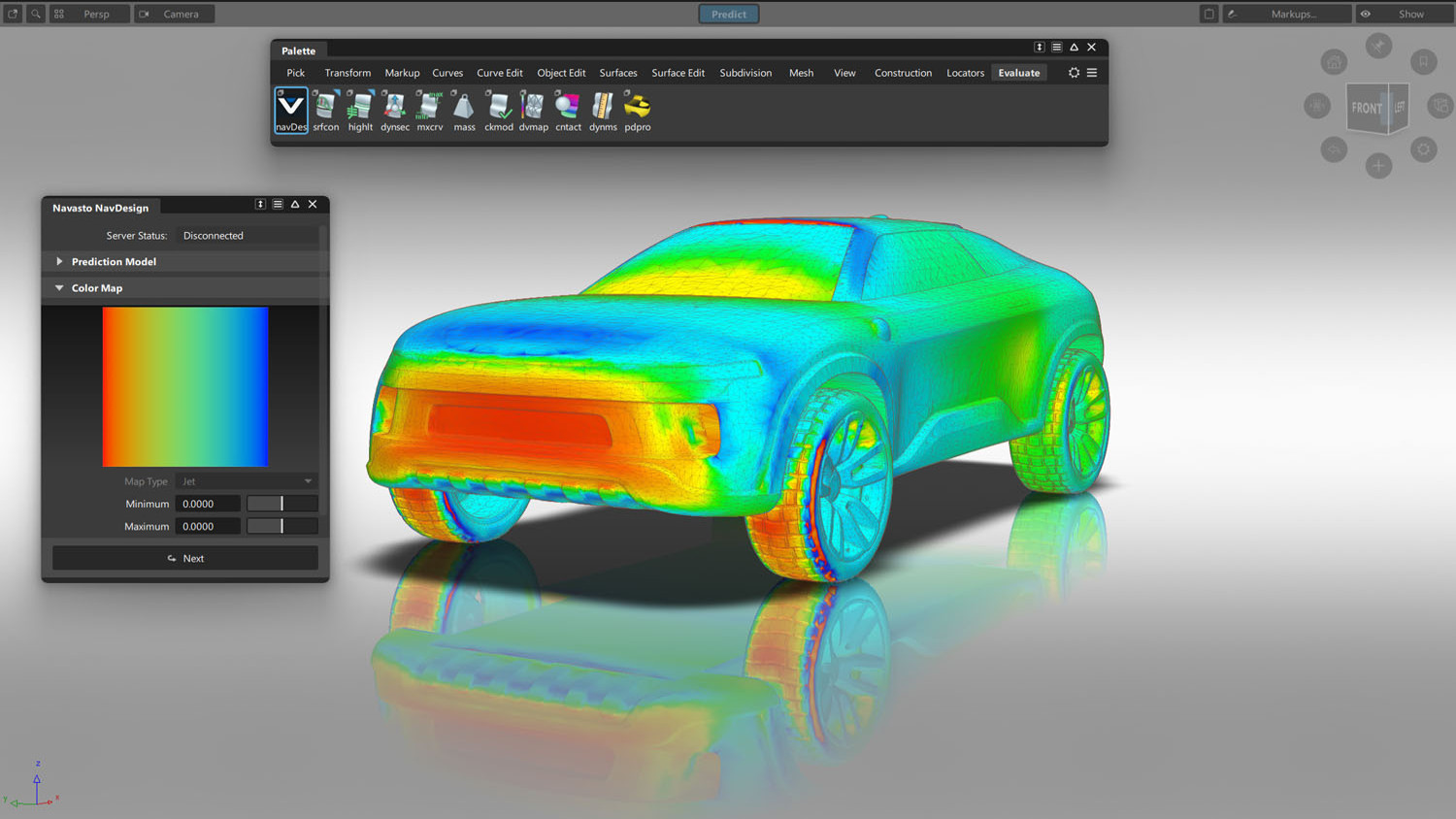

AI is also being used to rapidly accelerate engineering simulation and next year Alias will gain new AI capabilities through Navasto, an Autodesk acquisition announced at AU.

The German firm uses AI to bring Computational Fluid Dynamics (CFD) up front in the design process. Formula 1 teams use its technology to train AI models on CFD data, enabling them to ‘instantly predict’ results for geometries that haven’t been previously analysed. Other customers include Audi, General Motors and Volkswagen.

With a forthcoming Navasto plug-in for Alias, wind tunnel simulation will be brought into the early creative design process. The idea is that designers will be able to predict and optimise the drag co-efficient over an automotive exterior and its aerodynamics, while they craft high-quality, aesthetically pleasing surfaces. The ultimate aim: to reduce the likelihood of major redesigns during engineering.

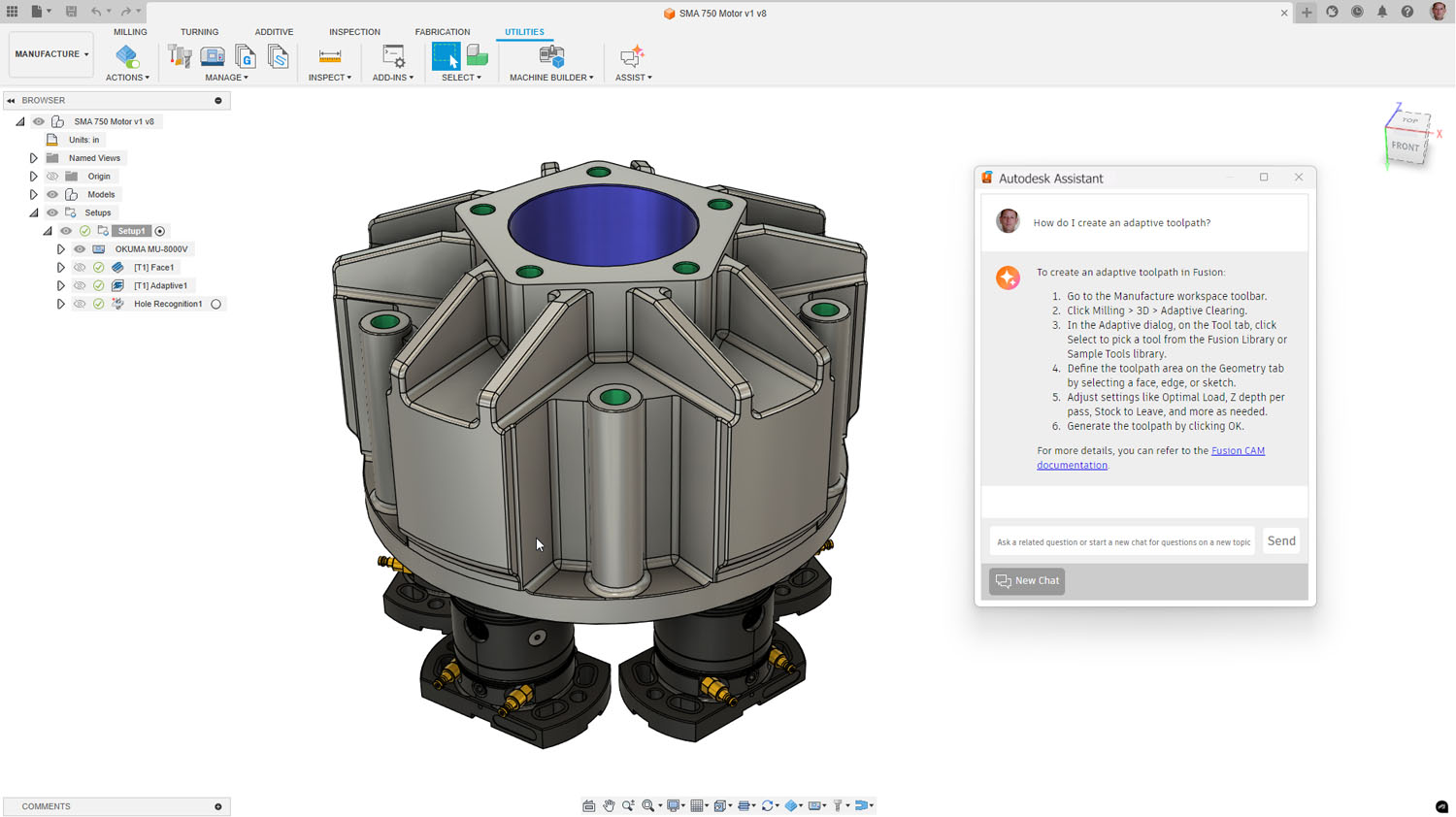

Autodesk is also working on general purpose AI through the application of Large Language Models (LLMs). With Autodesk Assistant, customers can use natural language to ask questions about products and workflows.

Autodesk Assistant has been available on Autodesk’s website for some time and is now being rolled out gradually inside Autodesk products. Autodesk Assistant in Fusion is billed as an ‘on-demand expert’ trained with both Autodesk-specific knowledge, such as Fusion’s capabilities, as well as general industry knowledge.

“The important thing about the system, is it’s going to be context-aware, so it’s understanding what you’re working on, what project you’re on, what data you’ve run, maybe what you’ve done before, where you are within your project, that kind of thing,” said Haley.

According to Autodesk, users of Autodesk Assistant in Fusion will be able to prompt it with questions like, “How can I program my toolpath to avoid slot milling?” or “What manufacturing methods should I consider for this part?”. Autodesk Assistant will then respond with Fusion-specific answers, or answers specific to manufacturing, and share hyperlinks to original sources.

Getting connected

Like most software developers Autodesk is harnessing the power of LLMs or vision models, such as ChatGPT and Gemini. “We can use them, we can adapt them, we can fine tune them to our customers’ data and workflows,” said Haley, citing the example of Autodesk Assistant.

But, as Haley explained, language and vision models don’t have any sense of the physical world, so Autodesk is focusing much of its research on developing a family of foundation models that will eventually deliver CAD geometry with ‘high accuracy and precision’.

Autodesk’s foundation models are being trained to understand geometry, shape, form, materials, as well as how things are coupled together and how things are assembled.

“Then you also get into the physical reasoning,” added Haley. “How does something behave? How does it move? What’s the mechanics of it? How does a fluid flow over the surface? What’s the electromechanical properties of something?”

According to Anagnost, the ultimate goal for Autodesk is to get all these foundation models talking together, but until this happens, you can’t change the paradigm.

“Bernini will understand the sketch to create the initial geometry, but another model might understand how to turn that geometry into a 3D model that actually can be evolved and changed in the future,” he said. “One might bring modelling intelligence to the table, one might bring shape intelligence to the table, and one might be sketch driven, the other one might be sketch aware.”

AI model training

Model training is a fundamental part of AI, and Anagnost made the point that data must be separated from methods, “You have to teach the computer to speak a certain language,” he said. “We’re creating training methods that understand 3D geometry in a deep way. Those training methods are data independent.”

With Project Bernini Autodesk is licensing public data to essentially create a prototype for the future. “We use the licence data to show people what’s possible,” said Anagnost.

For Bernini, Autodesk claims to have used the largest set of 3D training data ever assembled, comprising 10 million examples, but the generated forms that were demonstrated — a vase, a chair, a spoon, a shoe, and a pair of glasses — were still primitive. As Tonya Custis, senior director AI Research, admitted there simply isn’t enough 3D data anywhere to build the scale of model required, highlighting that the really good large language and image models are trained on the entire internet.

“It’s very hard to get data at scale that very explicitly ties inputs to outputs,” she said. “If you have a billion cat pictures on the internet that’s pretty easy to get that data.”

The billion-dollar question is where will Autodesk get its training data from? At AU last year, several customers expressed concern about how their data might be used by Autodesk for AI training.

This was a hot topic again this year and in the press conference Anagnost provided more clarity. He told journalists that for a generative AI technology like Bernini, where there’s a real possibility it could impact on intellectual property, customers will need to opt in.

But that’s not the case for so-called ‘classic productivity’ AI features like sketch auto-constrain or automated drawings, “No one has intellectual property on how to constrain a sketch,” said Anagnost. “[For] that we just train away.”

This point was echoed by Hooper in relation to automated drawings, “Leveraging information that we have in Fusion about how people actually annotate drawings is not leveraging people’s core IP,” he said.

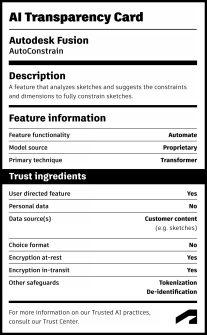

To help bring more transparency to how Autodesk is using customer data for training its AI models, Autodesk has created a series of Autodesk AI transparency cards which will be made available for each new AI feature. “These labels will provide you a clear overview of how each AI feature is built, the data that is being used, and the benefits that the feature offers,” said Autodesk CTO Raji Arasu.

Of course, some firms will not want to share their data under any circumstances. Anagnost believes that this may lead to a bifurcated business model with customers, where Autodesk builds some foundational intelligence into its models and then licenses them to individual customers so they can be fine-tuned with private data.

AI compute

AI requires substantial processing power to function efficiently, particularly when it comes to training. With Autodesk AI, everything is currently being done in the cloud. This can be expensive but, as Anagnost boasted: “We have negotiating power with AWS that no customer would have with AWS.”

Relying on the cloud means that in order to use features in Fusion like auto constraints or drawing automation, you must be connected to the Internet.

This might not be the case forever, however. Arasu told DEVELOP3D that AI inferencing [the process of using a trained AI model to make predictions or decisions based on new data] could go local. She noted some of Autodesk’s customers have powerful workstations on their desktops, implying that by using the cloud for compute would mean a waste of their own resources.

An interactive future

Autodesk is beginning to add clarity to its AI strategy. It is addressing AI from two angles: bottom up, bringing automation to repetitive and error-prone tasks, and top down with technologies like Project Bernini that in the future could fundamentally change the way designers and engineers work. The two will eventually meet in the middle.

Autodesk is keen to use AI to deliver practical solutions and the automation of drawings and constraints in Fusion should deliver real value to many firms right now, freeing up skilled engineers at a time when they are in short supply.

Meanwhile, it’s clear there’s still a long way to go before the AI foundation models being explored in Project Bernini can deliver CAD geometry with ‘high accuracy and precision’.

While Bernini is starting to understand how to create basic geometry, the 3D models need more detail, and Autodesk must also work out how they can be of practical use inside CAD. With rapid advances in text-to-image AI, one also wonders what additional value text-to-CAD will bring to concept design. One could also ask whether product designers or engineers would even want to use something like this to kickstart their design process. As the technology is still so embryonic it’s very hard to tell, and it’s important to remind us all that this is a proof-of-concept to explore what’s possible, rather than a practical application.

Meanwhile, as Autodesk continues to develop the complex training methods, there’s also the challenge of sourcing data for training. It will be interesting to see how Autodesk’s trust relationship with customers plays out.

While Autodesk’s long-term plan is to get multiple foundation models to talk together, this doesn’t mean we are heading for true design automation any time soon.

At AU Anagnost admitted that the day where AI can automatically deliver final outcomes from an initial specification is further away than one might think. “For those of you who are trying to produce an epic work of literature with ChatGPT, you know you have to do it iteratively,” he said. That same iterative process will apply to AI for design for quite some time.