Node Audio’s eye-catching Atom speaker system contains a hidden secret – a 3D-printed gyroid infill that gives it a distinct sound. Gabrielle Brown hears about a technology that sets Atom apart from its competitors

The Atom speaker is characterised by understated yet unmistakable luxury. Sleek and sculptural, it looks as good as it sounds, thanks to some special components hidden away from the admiring glances it commands.

Designed and manufactured in the heartland of British hi-fi equipment, Atom is the second product range launched by Cambridge-based Node Audio. It’s crafted to turn heads and packed with the latest tech for the best possible sound.

Designers Ashley May and David Evans clearly love sound as much as they love designing outside the box. As directors of design consultancy Studio 17, they have already developed products for a number of homeware giants, including Joseph Joseph and Fiskars.

In 2018, they founded Node Audio, launching their debut product, the Hylixa loudspeaker the following year What began life as a side project was soon a hit in the audio segment, garnering international recognition for its patented internal helix structure, which is designed to eliminate cabinet coloration of sound and to generate a deeper bass.

The goal with Atom, explains Ashley May, was to take the best acoustic principles from the Hylixa speakers and bring award-winning sound quality to an even broader audience.

With this follow-up to the Hylixa, May and Evans were looking to cater to a different market. “What I think we’ve learned in the intervening period is that our market is typically a bit more conservative and so our follow-up product tries to move a little bit more in that direction,” he says. “So we’re packaging our Helix technology within these speakers, but instead of it being in a sort of jet-engine shape firing forward, it’s now vertical in a more expected form factor.”

The hi-fi market typically offers standalone bookshelf speakers and taller floor-standing speakers boasting greater bass. With the Atom range, May and Evans wanted to address both of these needs by offering two models, with an optional floor stand for the smaller of the two.

Physical 3D-printed prototypes in combination with quick digital renders produced in Keyshot allowed the design team to both adapt original designs and test out brand-new ideas.

“We have the ability to produce bigger speakers if we want an even bigger floor standard with a bigger bass driver in the future. That’s the beauty of additive. You can quite easily test these things and prove the market before you produce too many of them.”

Sound space

The results are impressive. Sturdy but minimal, the Atom’s metallic accents reflect light. The speaker has four precise feet that give it the appearance of hovering rather than sitting. Visually speaking, it will make a statement in any room – but it’s the sound of these speakers that will really dominate the space, the result of its patented internal Helical Transmission Line or HTL.

Traditionally, internal considerations in speaker design have had to grapple with whatever space is available inside the speaker cabinet. With 3D printing, however, a speaker can take whatever form gives the clearest sound.

With Atom, the resulting helix creates a very low impedance path, because of its continuous round form that enables air and sound to both flow efficiently around it.

The HTL (a coiled acoustic waveguide) forms a continuous bass tube far greater than the cabinet size. The complex internal geometries can only be achieved with additive manufacturing. The long-throw woofer channels energy into a central chamber that feeds a precisely engineered helical pathway, reinforcing and projecting low-frequency output.

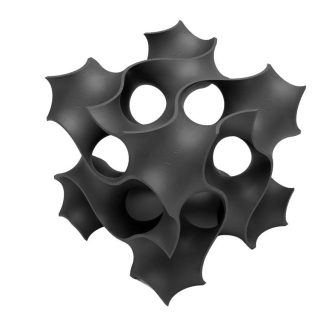

The elimination of sharp edges and parallel surfaces, now synonymous with the brand, improves acoustics and reduces degradation of stereo images. Launching with two configurations and a range of refined finishes, the Atom packs in not only the revolutionary HTL but also a new 3D-printed and patented MonoCell damping technology.

We wanted to create something that is both completely different and, frankly, better. It’s all done in the name of acoustic performance Ashley May, Studio 17

Damping debut

MonoCell is 3D printed from gyroids, giving its internal structures wave-like walls and hollow chambers that, by adding internal bracing to the design, adds stiffness to the overall speaker body, while adding less weight than traditional fibrous damping materials stuff ed into cavities. The result is a significantly reduced cabinet coloration and a clearer listening experience.

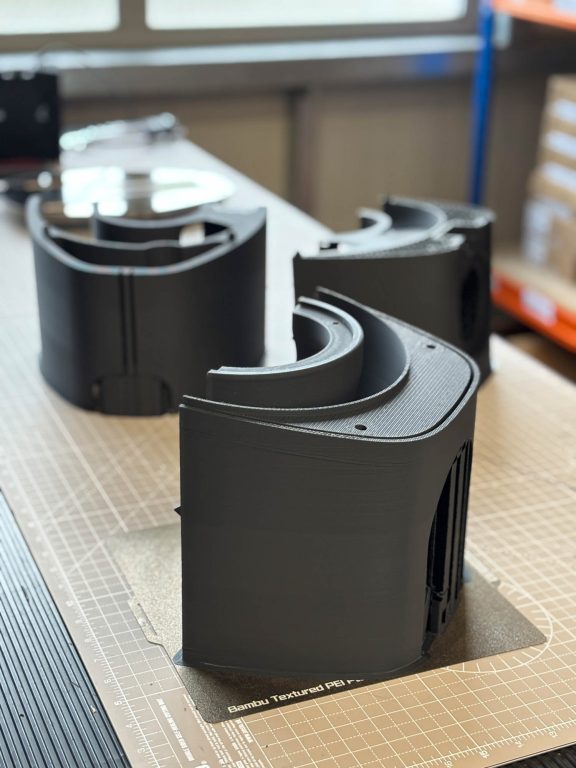

While the cabinet, electronics and hardware are designed and positioned in Solidworks, the new MonoCell damping technology required an entirely new workflow. To produce the new infill, gyroid modifiers in Bambu Lab Studio software allowed the designers to selectively apply the infill pattern to specific parts of the CAD model, ready for printing.

May explains how its goal is to replace traditional big heavy walled wooden boxes with the latest in materials science.

“Using additive, you can bring those two elements together, get rid of the wall stuffing, and have this really fine join with a lattice structure to damp the sound, but also provide a mechanical stiffness to the part, because it’s throughout the whole internal volume,” he explains, adding: “We wanted to create something that’s completely different from anything else in the hi-fi industry and better, frankly. It’s all done in the name of acoustic performance.”

Functionality is at the forefront of all Node designs. May and Evans’ experience in designing products for a wide range of industries means that they are not shackled by traditional acoustic designs and manufacturing techniques when it comes to creating innovative and unique products.

Additive at its heart

Node employs a combination of FDM, SLA and SLS 3D printing processes across the Atom range to create internal structures impossible to manufacture using conventional methods. While the Hylixa is built from dense, glass-filled nylon SLS, the Atom is manufactured using the more affordable FDM.

“We spent four years exploring different manufacturing methods and materials to give us the rigidity of SLS at a much lower cost. FDM has improved greatly over the past couple of years,” May explains. “What was once reserved for prototyping is now a viable production solution for us.”

After testing multiple size and speed machines, the team decided on using Bambu Lab printers, bringing in-house Bambu’s H2D printer and a fleet of its PS1 3D printers. The team speaks highly of their dependability, as well as their widespread use in printing bureaus.

May reveals that, after much testing, the designers settled on PLA filament: “We’ve experimented with all kinds of filled filaments and acoustically – and this is quite surprising – PLA does perform the same as the more exotic materials. So certainly for repeatability and ease of manufacture, PLA performs just as well, and there’s no reason to use additive infills.”

All of Node’s products are produced and assembled in-house, giving the team there full control over the design and manufacturing process. The creation of each and every component is carefully overseen and quality checked, and any changes immediately updated.

Node also downsizes any risk of 3D-printing production by producing its speakers in multiple parts. The design cleverly factors in connectors, clips and screw inserts, and once each component is printed and quality checked, the speaker is assembled using mechanical joints and strong silicon adhesives.

Unlike its more exclusive sibling the Hylixa, the Atom range will see Node expand the team to support the UK manufacturing of the range.

Fabric finish

Once assembled, the cabinets are then wrapped in a multi-layer acoustic fabric to support vibration control and offer the opportunity to expand the range of colourways and fabrics available.

“Initially, we were looking at an aluminium extrusion to cloak the 3D prints, but it quickly became clear that to produce something, it would be far too difficult to extrude such a large piece of aluminium, with lots of tolerance issues and quite expensive for the tooling,” explains May.

From further tests, fabrics were shown to perform well, especially thicker fabrics like felt, leather and those with a foam core. Node’s experiments in this area continue.

In an age when a good chunk of shopping is conducted online, communicating the message of sound quality to customers is a challenge the team is looking to overcome. “They need to see and hear it, and they need to understand what is so special about the way we’re manufacturing,” says Evans. To cope with the demands of an ever-growing online market, Node uses Blender to create smoke simulations that visually communicate the sound performance benefits that HTL delivers.

The Atom range is not just manufactured, but carefully crafted, speaking to May and Evans’ love not just for top-quality sound but also for innovative design and production methods that throw away the rule book.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here