Stratasys has announced the launch of SAF ReLife, a solution that transforms waste PA12 powder from 3D printers into surface finished parts.

The software-based solution can repurpose waste powder from bowder bed fusion printers including high-speed sintering, selection laser sintering (SLS) and material and binder getting.

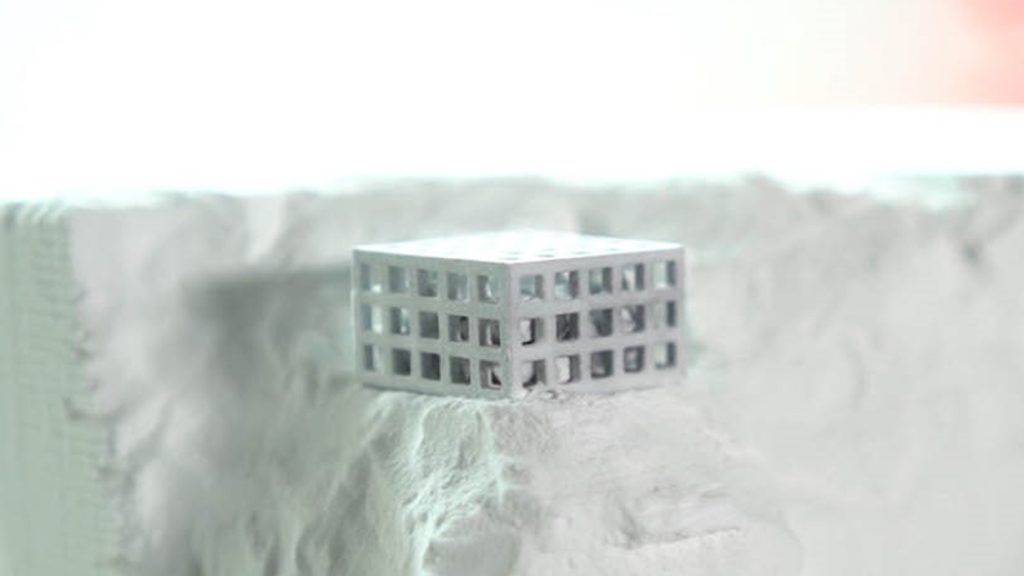

The powder can be used in the Stratasys H350 3D printer to print parts with a high-quality surface finish.

Using powder that would otherwise be discarded lowers the cost-per-part for manufacturers and reduces their carbon footprint.

To research the environmental impact of the SAF ReLife software, Stratasys partnered with Fraunhofer IPA to conduct a third-party Life Cycle Assessment (LCA).

The assessment revealed that reusing waste from powder bed printing can reduce the manufacturer’s carbon footprint by up to 43%, compared to standard production using polyamide 12 material.

“Our life cycle assessment demonstrates that Stratasys’ SAF ReLife PA12 solution can reduce the carbon footprint of the reference print job by 43% with the German electricity mix and as by as much as 89% when powered by renewable energy sources, compared to standard PA12,” said Fraunhofer research associate Chantal Rietdorf.

Service bureau Wehl Green beta tested the software with their SLS waste, and reported 20% savings in cost per part and a ‘substantial’ reduction in waste.

It was able to produce new parts using its waste within a 48 hour turnaround.

“This circular approach has reduced our environmental impact while maintaining top-tier product standards,” said Wehl Green manager and co-founder Javier García.

“We’ve cut production costs while producing parts that meet strict industrial specifications.”

The solution currently is available for Stratasys customers.