Nearly five years ago DEVELOP3D marauded North to visit Paragon Rapid Technologies, a Darlington model maker with ambitious plans for the 3D printing boom on the horizon.

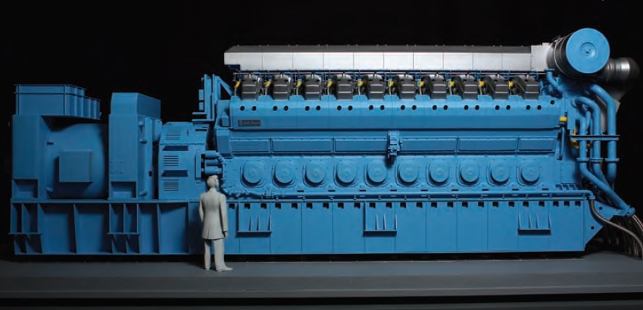

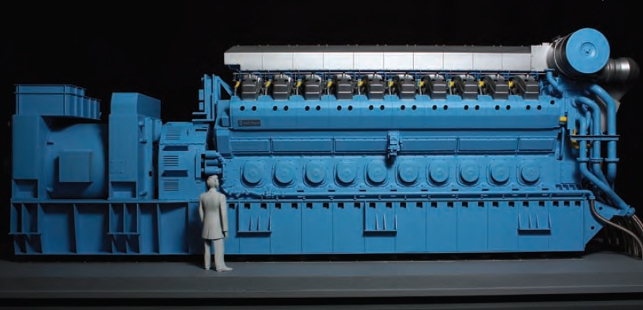

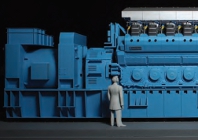

A desktop-sized scale model of a Rolls Royce Bergen diesel engine

This skilled company specialising in highlydetailed models, prototyping and short-run production already had the hands-on skills for product finishing, vacuum casting and silicone tooling; stereolithography (SLA) was next and it was seemingly set to change everything.

In short: it didn’t. The machines and their output simply slotted into Paragon’s workflow as another tool to be utilised for speed and detail, improving what it could offer to customers.

For trade shows, marketing events and boardroom presentations, it seems nothing comes close to having a detailed scale model in front of you, and Paragon has built thousands in all industries. A scale model of a giant turbine? A diorama of a proposed new oil rig and pipeline?

Paragon is now one of the ‘go-to’ companies for such displays, and it achieves it through cleverly blending all the tools at its disposal.

The company still takes in work from all sectors, including rapid prototyping, but its business model of seeking out niches has positioned itself as a master of creating models for heavy engineering firms.

Small print

A great example of this amalgamation of processes and materials is a bright blue Bergen engine built for Rolls Royce.

The base was fabricated from acrylic, the main body was CNC machined, all the little injectors and access panels were vacuum cast; the little piping and handles were SLS printed, along with the generator section at the end which crafted by hand.

“We used all the processes in-house, it’s hat we’re wanting to do: use the traditional methods and 3D printing to achieve this level of model making,” says Paragon’s business development manager Darren Webb.

“With rapid prototyping everything comes in and out the door so fast that it’s hard to have a foundation to build on. With the low volume production it’s regular work that can be used as a base for investment.

“We know that one of our strengths is the skills of the model makers – we employ timeserved model makers, and nearly everyone in the business, from manager, director to sales persons are all model makers as well.”

The business continues to grow, with a further facility extension planned, bringing more technology onsite, including a CNC machining workshop and another large build area SLS machine already on its way.

Model making at Paragon Technologies

Default