The highlights of the world’s most important additive manufacturing tradeshow went way beyond the printers themselves, says Stephen Holmes, who braved the hustle and bustle of the November 2025 Frankfurt show in order to share his impressions with DEVELOP3D readers

Formnext 2025 – Let’s get niche

Users need specific functions from their additive systems, and hardware suppliers have finally cottoned on to that fact. Tailoring machines to application needs and materials is now the way to go.

At Formnext 2025, attendees were exposed to some excellent use cases focusing on specific materials and uses. Take, for example, a liquid silicone 3D printer from RLP (Rapid Liquid Print), which produces parts with overhangs and smooth surfaces from a tank of supportive gel. As 3D printing increasingly shifts into the manufacturing of end-use parts, repeatability and qualification are becoming far more important. That, in turn, makes single-focus solutions more desirable over machines offering ‘jack of all trades’ flexibility.

Rapid Fusion, meanwhile, chose Formnext as the venue to unveil its military-focused LFAM Cerberus unit for containerised manufacturing, involving both AM and CNC methods [image above]. This supports distributed production out in the field, and in the harshest and most remote environments, with all the necessary kit neatly packaged into a standard shipping container and ready to print just 25 minutes after set-down.

Similarly, additive software companies are just as keenly aware that the one-size-fits-all solutions of the past often lack finesse. At Formnext 2025, Dyndrite and Materialise both announced dialled-in, system-specific build processors that offer customers better results straight off the printer. We can expect more targeted solutions like these in 2026 and beyond.

Formnext 2025 – Small and mighty

There’s never been a better time to upgrade your workshop, with many brands now offering tidy, capable and cost-effective desktop equipment. Bambu Lab arguably demonstrated the most electric presence across all four exhibition halls at Formnext. Its technicolour, double-decker stand was a hive of activity as makers, professionals and representatives of rival brands swung by to see what all the fuss was about.

Meanwhile, Fibreseeker was also attracting attention. Its desktop reimagining of Anisoprint’s continuous fibre 3D printing combined with its sub-$3k opening price is unlike anything we’ve seen before. Professionals should probably wait until production reaches some maturity and the company irons out any kinks, but there have been no shortage of people willing to throw money at the company’s crowdfunding campaign, which had topped $2 million at the time of writing.

Another eye-catcher was HeyGears [right], with its SLA technology and wide array of engineering materials (including some particularly nice clear resins and elastomers). This already looks like a solid option for users confident in taking a punt on SLA technology without local support.

A key theme is that all three brands hail from Asia and are quickly making their mark in elsewhere in the world with their speed, quality and materials geared for product development.

There’s still hope for Western brands, though. The Formlabs and Prusa Research booths were thronged with attendees, looking to check out either Formlabs’ new Tough Materials or an eight-material, multitool upgrade to the Prusa Core One. But don’t be surprised if your next workshop 3D printer comes from a brand that doesn’t share the storied histories of these more familiar names.

Formnext 2025 – Software eases adoption

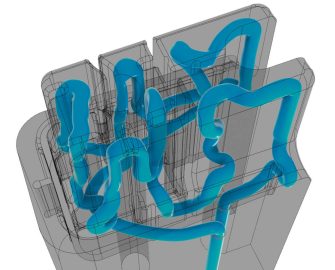

Dig past the hardware and there was plenty of software suppliers at Formnext, too, all eager to make an impact in the additive world. Design-led tools like Nureo are looking to optimise industrial elements where AM can be used, such as conformal cooling channels in tooling and factory line cages that flip over products.

Traditionally, these can be a pain to model and optimise, but Nureo can rapidly generate models that are ready to be printed and put to work on production lines.

Genic’s AI-generated conformal cooling software [right] focuses on developing the best cooling channels for 3D-printed injection moulding tooling, boasting some impressive results for both reducing cooling times and reducing shrinkage, all with a few simple clicks, freeing up time for engineers to go and be more productive elsewhere.

Renishaw’s RenAM 3D printers are a great example of how software upgrades are making tried-and-tested models more efficient, producing better quality output and improving uptime.

Renishaw’s new Libertas software improves surface finish and reduces the need for supports, while a new build processor developed with Materialise adds support for nTop implicit modelling and makes the platform attractive for new and existing customers alike.

Formnext 2025 – Old dogs have new tricks

It’s a sign of a maturing industry that product roadmaps are settling down a little, with existing technologies receiving minor tweaks in the interests of productivity and better quality end results.

This work is moving the industry away from the sci-fi wonder surrounding AM and closer to the heart of the matter: industrial equipment. Attendees got straightforward answers to questions like, “What does it cost?” That’s a big difference from previous years, where requests for even ballpark figures elicited evasive responses. On some stands, there were actual stats available, relating to machine and material CO2 footprints.

Some vendors didn’t even bring machines. Carbon’s stand, for example, was singularly focused on real-life user applications that are already hard at work today, creating products that range from NFL helmets, footwear to wheelchair covers. This highlights a growing awareness that AM is much more than just a machine and is best applied as part of a holistic solution.

Large-format additive manufacturing (LFAM) has fascinated me for years, but 2025 marked the point at which a growing number of established companies began to show off a more significant number and range of real-world applications. Full boat hulls, giant audio speakers and body panels for trains were all up for discussion, with brands like Caracol and Cead offering visitors the chance to literally climb aboard products built using their technology [above].

Seeing massive robotic arms at work is no longer the novelty it once was, yet there were still plenty of eye-catching developments to see at Formnext, such as a bungalow-sized orange LFAM cell from Moi Composites that outputs continuous fibre thermoset composites. With new developments and applications continually emerging, there’s still plenty of ceiling for LFAM to grow into.

Formnext 2025 – Precision counts

There’s a battle underway in metals 3D printing and it’s a battle in which size very definitely matters. It’s all well and good to 3D print, in a single build, a massive rocket engine that contains multiple channels, vents, pipework and nozzles – but just how clean and fine are the details and how long does it take to produce?

Added smartness could be the answer, in the form of more lasers and sensors. These feature in monster machines like the BLT S1025 and the massive, high-throughput Nikon SLM NXG platform [above], but adding more melt points to build chambers can create issues. Either way, the company that can best balance high throughput and fine details without trade-off s stands to win big.

For the present day, there were lots of exciting pre-build simulation software products on hand, both from big brands like Altair and Dassault Systèmes Simulia and from rapidly advancing independents like PanOptimization.

Vendors of build monitoring hardware and process optimisation software are also stepping up to help manufacturers get the best results from their additive manufacturing strategies. One of the most interesting of these is Additive Assurance, a company that has for some time been creating bolt-on, in-situ quality assurance sensors and process monitoring software. It’s now partnering with 3D printer OEMs to include its Amiris Inside sensor set-up in new machines. Nikon SLM, for example, will put Additive Assurance sensors inside the NXG platform.

UK-based Matta, meanwhile, showed off its AI optical monitoring technology for LFAM with Caracol, allowing it to detect defects and optimise processes along the way.