The Agrifac Milan is the only trailed sprayer on the market with self-propelled sprayers

Agrifac is in the business of precision farming and food production. With its range of agricultural machinery, it focuses on ‘growing the growers’, and, having started life selling crop sprayers to farmers in its local area around the small Dutch city of Steenwijk, it is now targeting a global market.

The company’s current line-up of crop sprayers differ in size and propulsion. The large, self-propelled Condor machine has already won design awards and the affections of farmers around the world. The other, the Milan, is a compact crop protection sprayer, pulled behind a standard tractor.

The Milan sprayer is hailed by Agrifac as one of the most innovative sprayers in the world, and the only trailed machine on the market with self-propelled sprayer technology.

Its overall design is a testament to Agrifac’s R&D department, of which Jarno Habing, product manager for the Milan range, is extremely proud.

“We’re an innovative company,” says Habing, speaking from the company’s HQ. “R&D is 20% of our company. We’re driven by technology revolution and we’re almost always first to market.”

For example, key innovations focus on 20 spray nozzles positioned at strategic points on each boom. These nozzles ensure that every drop of spray arrives at the right moment, at the right size, exactly where it is needed.

The nozzles for Agrifac’s larger crop sprayers are designed as three connecting parts, comprising two metal components and one injection-moulded plastic part.

Given the smaller footprint of the Milan model, however, there was no way this approach could be reused, even in a shrunk-down format. This challenge gave Agrifac the opportunity not only to redesign the component to add extra efficiencies, but also in a way that made it possible to use additive manufacturing, with its knock-on production benefits.

Agrifac follows a ‘4e’ design philosophy, based on efficiency, economy, ergonomics and ecology. In keeping with this, and given the initial quantities of parts required, it was decided that 3D printing the nozzles would prove the most efficient and economical means of production.

In addition, 3D printing would enable Agrifac to trial different dimensions in the early stages of production.

However, the choice to use additive manufacturing threw up new challenges. Constant exposure to chemicals, the weather and the need for regular removal and adjustment needed to be taken into account.

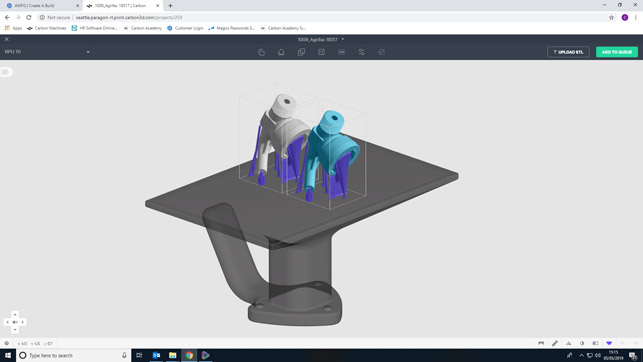

With some minor tweaks to ensure build strength and efficiency, the team at Paragon Rapid Technologies built the tough parts using Carbon’s DLS technology

In addition, these parts need fine apertures and even finer (but robust) screw threads, which means that most polymers used in laser sintering or stereolithography (SLA) printing aren’t up to the task.

Agrifac was sending out at least five replacement nozzles a week to every farmer using the Milan sprayer, primarily as screw threads were being damaged when nozzles were removed and replaced for regular cleaning.

Printed in a rigid polymer, the nozzles are able to withstand water pressure, chemical exposure and outdoor conditions

Agrifac – introducing digital light synthesis

Determined to find an additive manufacturing solution, the R&D team turned to experts Paragon Rapid Technologies in the UK, and a range of tough materials designed for use with the Digital Light Synthesis (DLS) process developed by Silicon Valley-based Carbon.

Agrifac and Paragon identified two potential Carbon resins with the suitable attributes of toughness, stiffness, temperature- and water-resistance for producing the part. These were Cyanate ester CE221, a high-performance material with excellent strength, stiffness and high temperature resistance up to 231°C ; and rigid polyurethane RPU70, a tough material comparable to ABS, but with added strength, toughness and very little water absorption.

While the first CE221 parts proved workable, they required a greater number of support structures and the material proved brittle in comparison to those built in RPU70.

Paragon’s knowledge of the Carbon DLS process helped improve both parts, simply through further edits to parameters and orientations, but it was ultimately decided that RPU70 was the appropriate material choice for the final production part.

“Designing for Carbon is a slightly different process than for traditional 3D,” explains Paragon’s DLS manager Roy Crombie. “We really wanted to comply with Agrifac’s 4e philosophy, and we knew we could deliver on efficiency and economy with just some minor tweaks to the design,” he says.

“We advised on some slight adjustments to a couple of radii and trialled the design on two or three different orientations to see which yielded the right results.”

Agrifac now has a reliable source of nozzles that can withstand all the forces that farmers, and sprayers, can throw at them.

“The DLS solution was not the cheapest option for us when we compared it with other 3D print technologies,” says Habing. “However, it was the most robust. I believe that we are close to offering a lifetime guarantee with these nozzles and, compared with the other options, that is a significant cost saving,” he says.

“We’re not being called up by frustrated farmers every five minutes demanding new nozzles. We’re not delaying their spraying processes trying to keep up with demand. We’re not impacting our ecology ethos with throwaway pieces. Our customers are very happy. That always means great savings for us.”

Agrifac found that not all 3D-printed parts are created equal

Default