When a glamorous restaurant wanted to add a branding spark to its desserts, it found the answer in fast and safe 3D-printed vacuum mouldings that enable it to customise guest meals

Stretching from the sunny beaches of Spain coast to northern Sweden, each of Urban Italian Group’s restaurant locations has its own strong identity and tells a distinctive story.

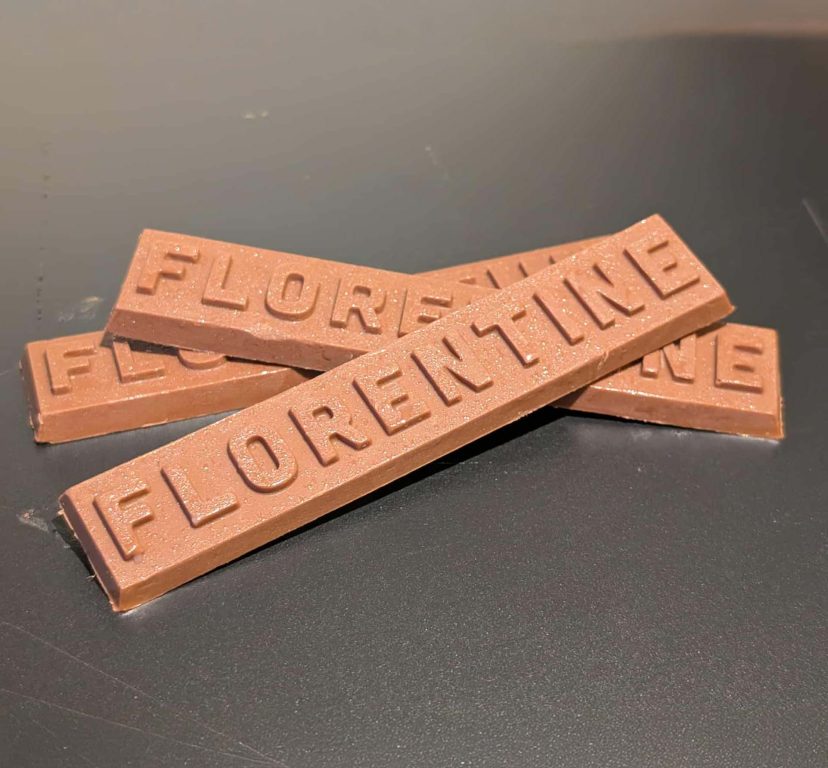

Draped in extravagance and bright colours, the group’s Florentine restaurant in Stockholm offers a reimagining of a 1970’s Italian movie scene. For its opulent desserts, the restaurant management wanted to create a custom centrepiece that could become its calling card for diners – a pink chocolate bar proudly stamped with the name of the restaurant.

Some initial research by staff revealed that a single metal mould would cost around £1,500 and would take several weeks to reach the kitchen. Determined to find a more effective way, the team at Florentine reached out to local 3D technology reseller 3DVerkstan to see if the specialists there could help identify a better and more cost-effective solution.

An appetite for feedback

An SVG file of the restaurant logo was sent to 3DVerkstan, along with information on the desired dimensions. One of 3DVerkstan’s designers then quickly built a 3D CAD model using Autodesk Fusion. A prototype was 3D printed. On presentation to the client, the main feeling was that it seemed too large.

Armed with this feedback, digital technologies helped the team refine the size and logo placement, before a final model was produced using a Formlabs Form 4 3D printer.

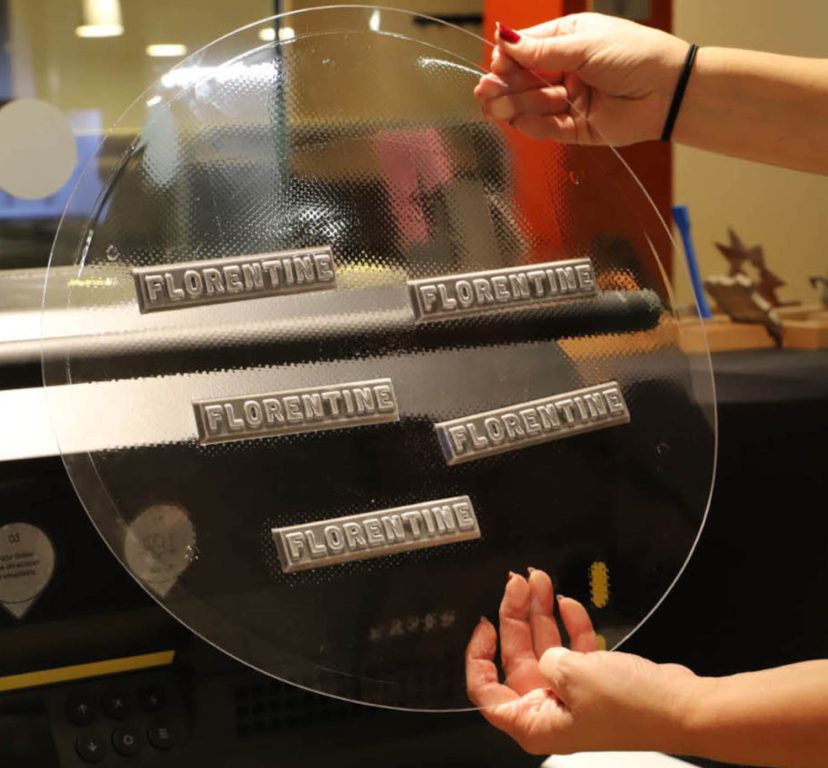

The smooth surface of the SLA model made it ideal for vacuum forming, using a Mayku Multiplier, creating multiple moulds using its PETG vacuum forming sheets. A special effort was made to prevent air pockets in the mould, which led to the integration of custom air holes that enable the vacuum-forming sheet to seal tightly around the ‘chocolate’ model and avoid air pockets.

The resulting workflow meant that each reusable mould could be produced for just £10. The overall price to develop the design cost a little over £100 and delivery happens in days, not weeks. The process also means that the design can be customised for future events, and new moulds can be produced on demand in a matter of hours should older ones break.

The resulting chocolates add a unique element to each Florentine dessert, enabling diners to cap off a delicious meal with friends and family not just with a sweet treat, but also a branded experience that gives them a real taste of the restaurant’s unique identity.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here