Autodesk has teamed up with materials science master, Granta Design, to create a materials selection system that is built directly into Inventor 2012. By Al Dean

If there is one technology that is the cornerstone of developing more sustainable products, it’s Life Cycle Assessment (LCA). For all the talk about whole systems design, carbon footprint, embodied water and energy, the simple fact is that when distilled down, everything points to materials selection. This is something that Autodesk has picked up on with its sustainability efforts over the last couple of years.

Those familiar with Autodesk’s Labs (labs.autodesk.com) may know Project Krypton, a tool that gave users feedback about the environmental impact of his or her current design, amongst other things.

Autodesk has now continued its focus on CAD-integrated sustainability tools and developed a brand new product called Eco Materials Adviser, which is part of the Inventor 2012 product offering. This has been made possible because Autodesk formed a partnership with one of the leading organisations dealing with materials data and selection, Granta Design.

Granta is legend amongst materials geeks (a club of which I’m unabashedly a member). Its roots lie with Mike Ashby and David Cebon, authors of the Ashby/Cebon method of computer-aided materials selection, which is taught in almost every design or engineering course across the globe.

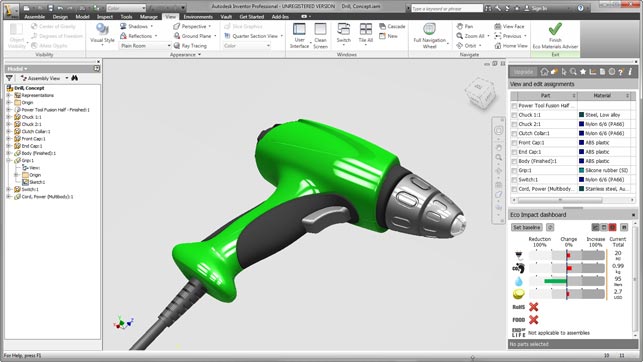

Final design of hand drill in Autodesk Inventor featuring a silicone rubber grip instead of natural rubber, which uses a large amount of water in its manufacture

Over the last 30 years, Granta has built on its academic foundations and has grown into a global leader in materials intelligence. It provides both raw data and a set of tools that assist the intelligent selection and management of materials and manufacturing information.

Prior to the launch of the product, I spoke with Autodesk’s sustainable products manager for manufacturing, Sarah Krasley, to get the background of the project’s genesis. I asked how Autodesk came to be working with Granta, a company that Krasley had also been familiar with since studying industrial design in New York.

“When we started looking at how we develop sustainable design functionality I heard over and over again, the frustration from designers and engineers that they need data. They were saying ‘I either have to go to several stakeholders inside my company to find good data or I use Google searches to try and find data and all manner of different data sources.’

“I just heard over and over again quite a bit of frustration around the whole subject. So, it seemed logical to go to the world’s largest and most reputable materials database company and see if there was some possibility of a partnership. It turns out that yes, there was and this was how we got involved together.”

Metrics

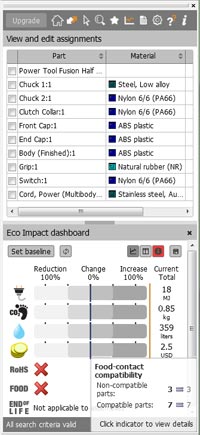

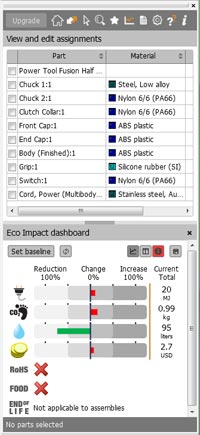

The software is distributed with every seat of Inventor (except LT). It can be found under the environments tab, and opens a panel to the right of the user interface.

The tool looks at either the part or assembly you’re working on and the materials you’ve chosen (Inventor is already supplied with a pretty extensive range of materials). It then connects to the Granta MI Materials Gateway over the web to look up additional information. In short, the system gives you feedback on three major areas of material information.

The first, as you’d expect, is eco-material properties. These include carbon footprint, embodied energy (the energy required to mine, process & create the material), and the embodied water (the equivalent for water).

Alongside the eco-values, it also gives you feedback about a couple of areas that typically aren’t factored into the process. The first is cost, and here it gives you a ballpark figure for the raw material costs of your product.

While not directly connected to material prices on the stock indexes, the tool does link up to the Granta Materials database and cost is kept up-to-date on a regular basis. The system also has two flags for RoHS and Food Grade materials.

Pronounced ‘rose’, the Restriction of the Use of Certain Hazardous Substances is an EU-led directive that bans the use of six specific substances in products and is led by the electronics industry. While not as comprehensive or as consistently updated as the list of substances in another EU-led directive, REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), it is still key and gives you quick feedback when you need it most.

The last is the Food metric. Essentially, this a check to find a material’s suitability for food contact. The primary sources are categorised by material and the sources for the checks differ. As ever, these ratings are guidelines, at a generic level. The ‘small print’ always states that it is the responsibility of the user to determine the status (re food-contact compatibility, in this case) of the specific material grades they plan to specify.

Finally, the last metric is End of Life. This gives you feedback about the material in terms of disposal, recyclability and such. Unfortunately, the current product doesn’t give you this information for assemblies and only works on a part by part level. This is because the system has no knowledge of how the parts are assembled or manufactured. For the latter, think about injection-moulded parts with metallic inserts, over-moulded or multi-shot components. That said, Autodesk has stated that in future, an upgrade will be available that addresses this need.

In use

Once you have your initial design concept (or even an older generation product for which you’re conducting a design refresh), you load it up and have a quick look at the results. Good practice at this stage is to set the baseline. This gives you a basis for comparison against subsequent rework, whether that’s down to a geometric design change or using the built-in search, selection and filtering tools to find alternative materials.

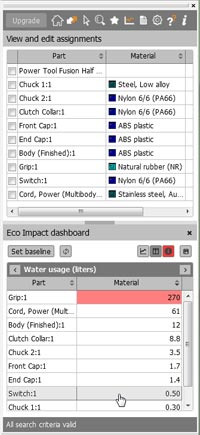

The system presents you with graphical feedback on the major metrics in chart form, so you can see exactly where your choices affect your product – its environmental and performance impact and of course, cost.

Alongside these graphically-led tools, there are also fuller reporting capabilities. You can dig into each metric to discover more. If your organisation has specific sustainability initiatives (such as reducing corporate carbon footprint), then you can also dive in and discover your product’s performance by impact criteria.

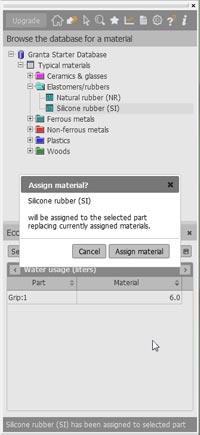

Also, for those new to the subject, or those without wider materials experience, as the system links directly into the Granta database, you have a huge resource of material data-sheets, processing information and the like at your fingertips, directly from within Inventor.

Limitations

Now, they’re not going to give you everything for free, are they? As you’d expect, there are plans for a multi-level product, but the base-level product is still pretty usable in its current state. The major limitations are two fold. Firstly, you get a ‘starter’ set of 80 materials in the free version. Upgrading to the full version gets you broader access to the Granta materials database (though there is no price information or a delivery date as yet).

Secondly, the assembly tools will only roll up values from 20 parts within your assembly. It’ll choose the first 20 parts in your assembly (instances don’t count as a single part) and at present, there’s no mechanism to choose which parts are assessed. There is a nice work around in that you can open up sub-assemblies and run the assessment on those, but it’s a bit of a fudge and I’d like to see Autodesk address this quickly.

Downstream use

While this tool is developed for the front end of the development process, it can also feed valuable data downstream. Firstly, the values you create for the various metrics can be pushed into each part’s metadata (or iProperties). That means anyone opening those parts can have access to the information and it can be transferred and managed in data management. Also, recycling information can also be used downstream, particularly if you’re looking to use Autodesk’s Inventor Publisher system for creating service manuals or end of life treatment instructions, either in paper form or digitally.

Conclusion

Autodesk and Granta Design have done an excellent job with the first release of Eco Materials Adviser. It’s not a mainstream type of tool as yet, the rise of this type of design-system integrated tool has yet to happen. That said, economic, business and legislative pressures relating to sustainability and compliance are only going to increase, all across the globe.

As a result, being able to load up a digital product model, even in its nascent form, and gaining insight into the environmental impacts of that product is going to become more and more critical for the design and engineering community. Yes, there are limitations in this freely distributed version, but it’s certainly a start.

The fact that you can work with assemblies, rather than single parts, is a bonus compared to competitive solutions and the fact that there’s an upgrade coming that gets you access to the might of Granta’s materials data, is very exciting indeed.

Design and engineering is about exploration followed by a narrowing down of ideas to reach an ideal solution. As we move towards an era in which design and engineering is not only about function, form and cost, but also environmental impact, having this type of capability built into your workhorse design tool will soon turn from a ‘nice to have’ to an ‘absolutely essential.’

Workflow: assessing which materials to use in the design of a hand drill

Stage 1. Begin using the Eco Materials Adviser by choosing “analyse” from the start screen. Eco Materials Adviser installs and starts searching the model on-screen to begin analyzing the materials used in its assembly.

Stage 2. It shows how much electricity is used to create the assembly; the carbon footprint for manufacture; the amount of water used and total cost. This helps the user weigh up the ‘green’ requirements against design/engineering factors.

Stage 3. Zooming in on the water usage of this assembly, we find that a grip made of natural rubber required a large amount of water in its manufacture.

Stage 4. The user has decided that the use of that much water is a concern, and is looking for alternatives. On this screen, the user searches for a material which has better water usage properties, but is similar to natural rubber.

Stage 5. Eco Materials Adviser suggests an alternative, silicone rubber. Choosing this material will reduce water usage dramatically, so the user assigns silicone rubber to the grip.

Stage 6. Now the Eco Material Adviser has analysed the assembly using the new material, and is showing huge water savings, with slightly changed eco impacts in other areas.

www.autodesk.com / www.grantadesign.com

A materials selection system from Autodesk and Granta Design built directly into Inventor 2012

No