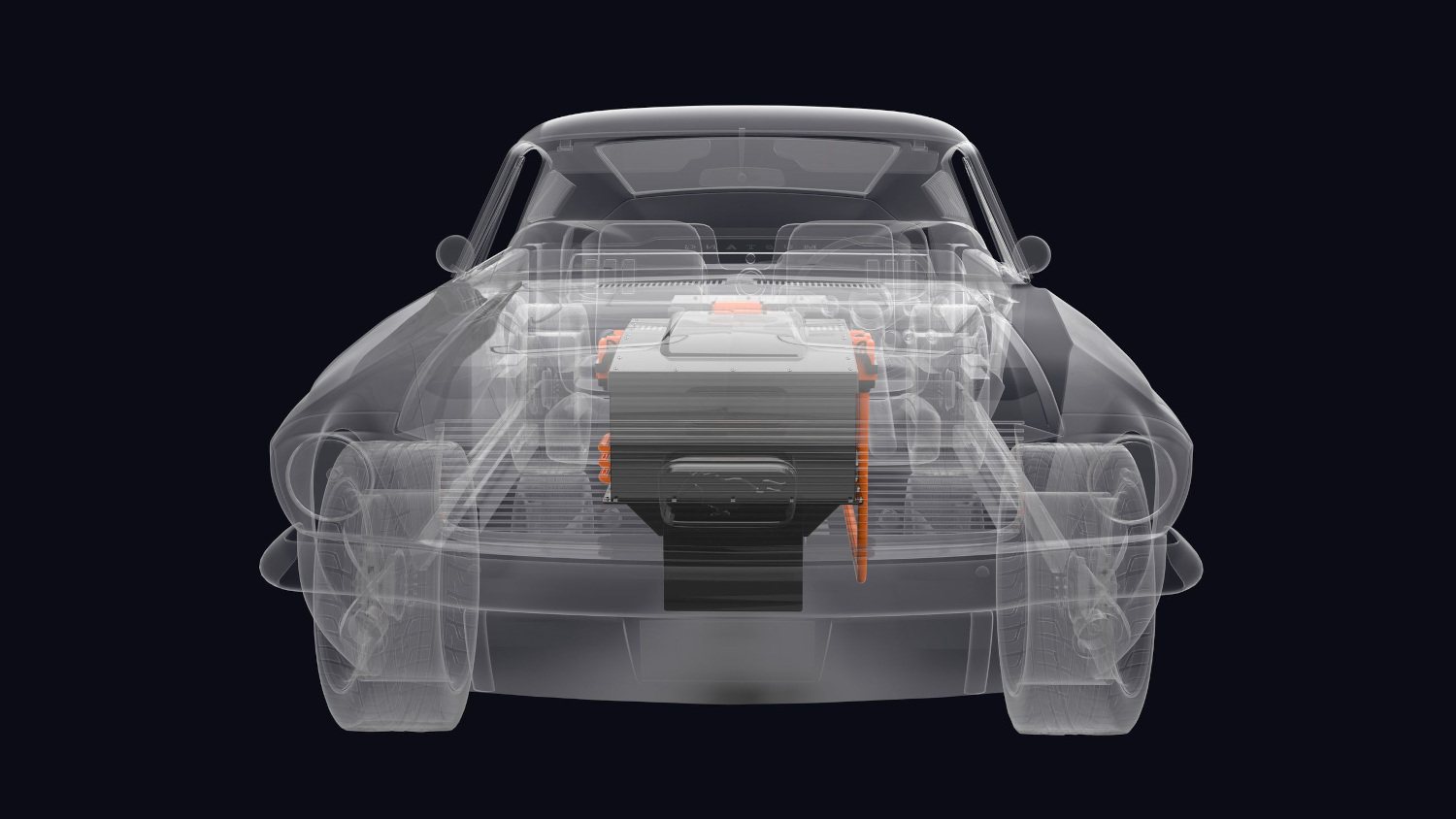

While the classic car world often looks to the past, Fellten is proving that the future of retro rides is electric. The UK-based company turns beloved automotive icons, like MINI Coopers, Porsches, and Land Rovers, into zero-emission machines without compromising the chassis or character of the vehicles.

The company’s approach isn’t just about swapping engines; it’s about reimagining what classic cars can be, blending heritage with innovation in a way that honors the past while (literally and figuratively) charging into the future.

Engineering for circularity

By swapping out combustion engines for advanced, custom-shaped battery systems, Fellten eliminates the need for new raw materials and extensive re-manufacturing.

“The goal is to basically give all of these classic cars a new life by creating a fully reversible solution that you can bolt in without changing the bones,” explains Lucy Dicken, design engineer, Fellten.

“We’re fundamentally designing a battery that’s normally underneath a car and making it engine-shaped to put under the hood,” Chris Hazell, co-founder and CEO, Fellten, elaborates. “At the same time, we’re doing this without making any modifications to the original chassis or vehicle at all.”

Digital development in Autodesk Fusion

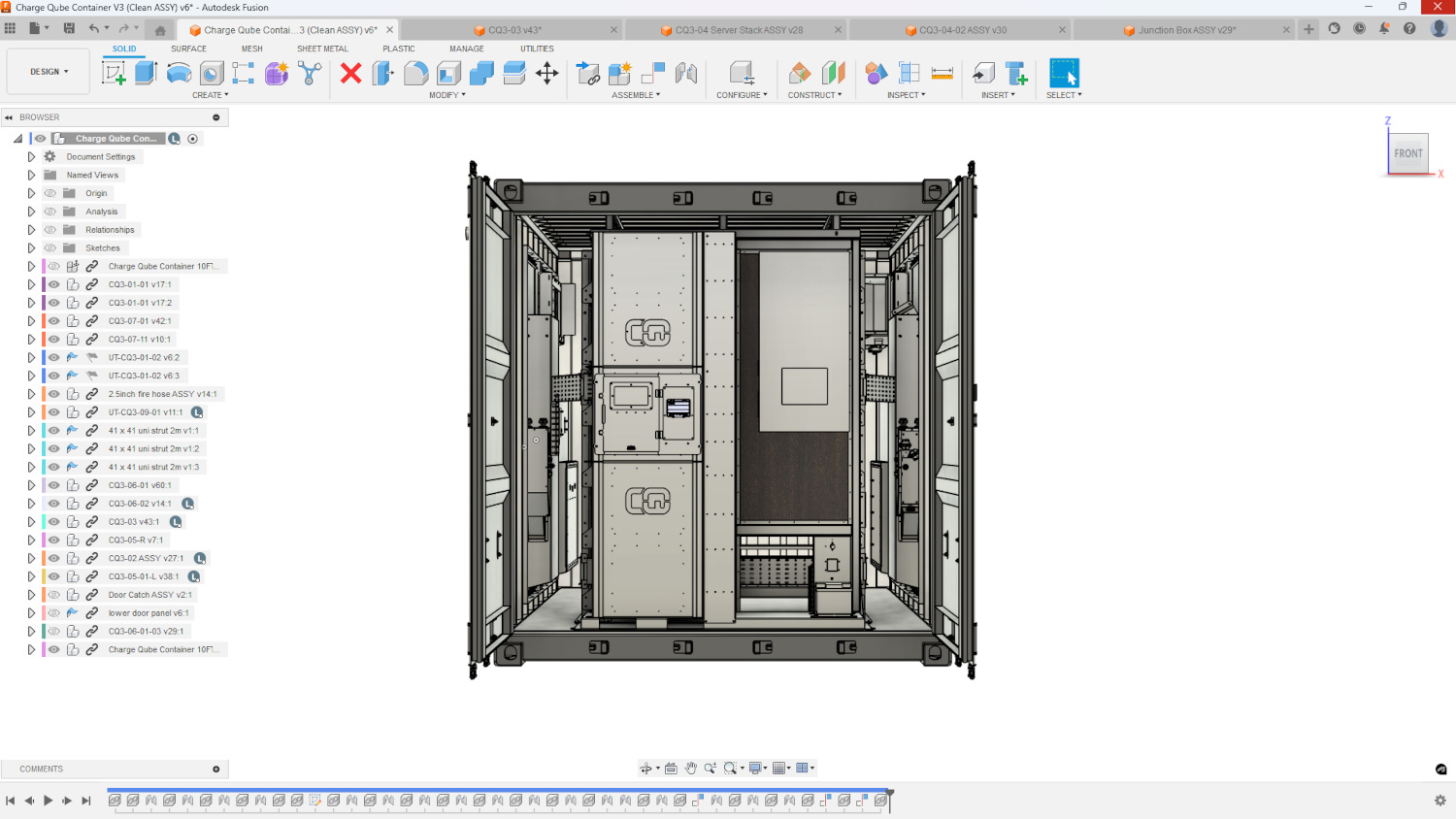

Every retrofit is a unique engineering challenge. Working in Autodesk Fusion, Fellten’s team translates high-precision scan data into functional CAD prototypes. “We get a lot of scan data that we import into Fusion just to make sure our designs will fit before we go on to prototype and then manufacture to install in real life,” Dicken notes.

Prioritizing accurate weight distribution, critical for authentic handling and safety, their collaborative cloud workflow mixes design reviews, iterative modeling, and simulation—all completed typically within a three-month cycle.

“With Fusion, we can basically take every single component, visualize it in a 3D space, and test multiple iterations quickly,” Hazell adds. “If you did this physically, it would take months and months, and you’d spend a huge amount of money on materials and trying things out.

“In the CAD world with Fusion, you can very quickly design, develop, and test. We can also do stress analysis and even look at things like flow rates with our liquid cooling plates to make sure we’re getting the right cooling systems for the batteries.”

Beyond cars: Fleets and infrastructure

Fellten is expanding beyond classic automotive retrofits by designing battery packs for new marine applications and developing scalable energy storage for fleet electrification.

Their latest product, Charge Qube, is a mobile solution that extends the life of EV batteries by enabling rapid, location-flexible charging for electric vehicle fleets. It supports both grid and renewable sources, and deploys easily in remote environments.

“The main goal for Fellten is to provide a more sustainable future, looking at up-cycled battery packs, especially with the Charge Qube,” Dicken shares. “We want to provide a circular economy for end-of-life battery packs, giving them another use and providing a charging solution that can be deployed basically anywhere in the world.”

“What excites me most about Fellten is the fact that we’re actually going to start making a massive environmental difference,” Hazell concludes. “Yes, we’ve been saving beautiful classics and retraining people into a new industry. But with our energy storage products, we’re actually going to be able to get high-emission van fleets transitioning to electric faster.

“We’re going to help that transition to a net-zero world as fast as possible, and we can use Fusion to design these products to help make it happen.”

Learn more about how Autodesk Fusion can power your design-to-manufacturing workflow here.