The potential to capture physical objects in a digital workflow has been through something of a renaissance of late. Whether it’s the introduction of dramatically lower cost devices at the entry level (see the use of the Microsoft Kinect 3D capture device as an inflection point) or being able to laser scan as part of a metrology and inspection workflow at the other end of the price spectrum.

The EinScan Pro gives you pure geometry capture as standard, but with the addition of the camera unit

The result is that much more of us are now aware of the potential benefits and there’s a greater level of support for the mesh or point cloud output creeping into all our workhorse systems.

Devices are typically split into two camps. For the scope of this review, we’re going to be looking at a product that’s firmly in the ‘capture to support design’ camp and here we typically find two types of device available.

The first is a stationary device, often linked to a turntable, that affords you form capture in an automated manner.

You place the item on the turntable, hit go and the hardware rotates the part incrementally, capturing a scan at each step.

Given knowledge of the rotation steps, the software can usually stitch together each of these scans to provide a good overall form.

If there are inaccessible parts or the part needs to be readjusted to reach them, then that’s also usually accommodated in the software.

Then you have a more portable, typically handheld, device. This uses either the object’s texture or a series of registration marks, to allow you to ‘wave’ the scanner over the surface of a part and capture its form.

One is more manual, but provides ultimate flexibility and portability, while the other gives a more automated, but restricted working volume. If you typically work on a common ‘type’ of product, you can usually pick the best approach, but many of us work across different product types, sizes and in varying environments, so the case isn’t as clear cut.

The sweet spot between the two is precisely where the EinScan Pro comes into play. It has been developed and manufactured by laser engraving specialist, Shining3D, a company also having a background in both scanning and 3D printing, in China and is sold in the UK by Concurrent Design Group in Alton. So let’s find out what it can do.

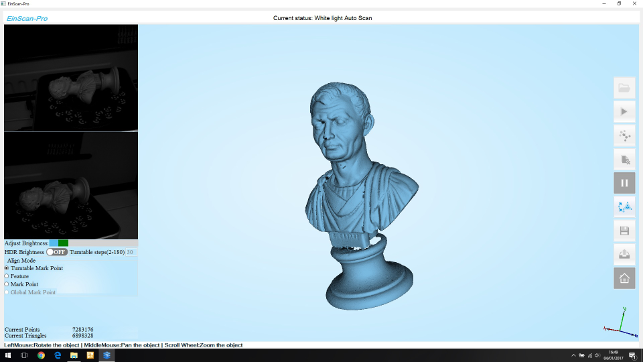

Shining3D’s software works well with its hardware, giving you control and real time feedback on scan jobs

Use as a hand-held scanner

The EinScan Pro’s main unit is comprised of two cameras and a projection unit that emits a white light pattern.

This pattern is tracked and captured by the two cameras, point triangulated and fed into your workstation. This is, as you might know, the basis for any structure light (or white light) scanning device.

On it’s own, the device works like any hand held scanning unit. Once it’s connected (via USB) to the software, you begin your scan job by moving around the object slowly.

You’ll see the object start to appear on your screen and as long as you’re slow and careful, passing the device over the object’s form, you’ll grab everything that the cameras can see.

The device works best from a distance between 300mm and 500mm. If you’re used to using these types of devices, you’ll know how it works, if not, you quickly get used to the process.

The software supplied with the system is pretty decent. Tracking is maintained nicely if you’re methodical, and you’ll find that it’ll recapture the tracking process quite easily.

Once you’ve captured the geometry, you start the system processing it and much of this is automated, with the addition of some manual clean up tools. Once complete, you can then move it onto the task in your workflow – whether that’s further work in a 3D scan data processing application, in your CAD system or something else.

Interestingly, the base unit just captures geometry, but if you’re also looking to grab textures from your physical object, there is an add-on. The colour camera/texture mapping add-on (costing £695) is a small additional device that attaches to the side of the scanner unit and will capture textures as you work through the process.

This is pretty much how you use it as a hand-held scanner. Now, what about a more automated process and less waving your arm around like a trainee wizard?

In its portable form, the EinScan Pro is a solid hand held scanner

Automating the process

In addition to the base unit and camera attachment, there’s also another add-on called the “Industrial kit”, which is also priced at £695.

This is comprised of a tripod that’s set-up for the device and an automated turntable.

You connect the turntable to your workstation, fire up the software and choose the Automatic Scan option in the software.

This allows you to define the number of scans you want to capture, the rotation angle and a few other options. You then set the system running. The software rotates your part to the required angle, captures what it can see, then rotates again, doing another capture with each increment.

When combined with the industrial kit add-on (a tripod and turntable), the EinScan Pro becomes an automated scanner

Technical specifcations

Now that we’ve got a good handle on how it works, let’s look at the specifications of the kit.

The scanner unit has two modes – rapid scan and HD. Rapid Scan gives you a scan accuracy of around 0.3mm and captures 15 frames per second, and is ideal for parts around the 150mm to 4,000mm size.

HD mode boosts the scan resolution to 0.1mm, but you’ll sacrifice scan speed as this drops to 10 frames per second. But it does enable you to capture smaller objects, starting at around the 20mm mark. You also don’t get texture capture on these settings either.

When you’re using the turntable and tripod, things are a little more focussed in terms of resolution (dropping again to 0.05mm resolution) but here the trade off is distance between the turntable and unit, working between 30mm and 150mm and the weight limitations of the turntable (2kg).

In conclusion

The EinScan Pro is a tidy unit that delivers some nice results whichever way you use it. What’s interesting is that the system gives you the best of both worlds, automation and portability when you need it. Yes, the software looks a little odd, but once you’ve got a handle on how things work, operating it as a handheld or an automated system, is easy, quick, and gives you a lot of options.

Today, budgets are tight and having a system like this on hand is going to solve a lot of issues or remove some outsourcing work.

After all, rather than paying for services, you can now afford to purchase one unit that does most of the things you’ll need to do – as it’s available at a pretty stunning price for a unit of this quality that can deliver this resolution of results.

The texture camera might not be the most useful in a design or engineering context, so you need to look at your workflow and investigate future requirements to see if there’s a fit.