The combination of PowerShape and PowerMill is at the centre of Autodesk’s advanced manufacturing solutions. Al Dean takes a look at what’s new and updated in the latest releases from two systems that have mastered design and manufacturing

At DEVELOP3D we’ve always been fans of the Delcam products and as we discussed last month, times are changing for the flagship solutions now under Autodesk’s advanced manufacturing banner, PowerMill and PowerShape.

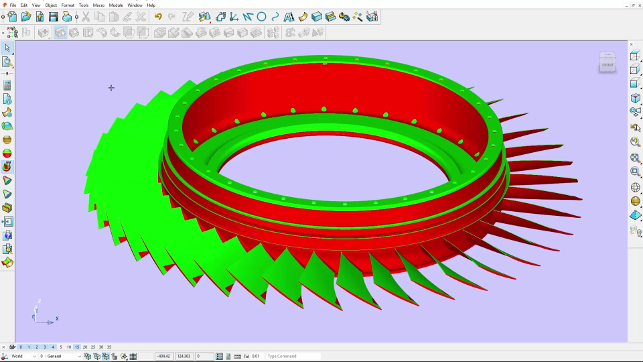

The new Accessibility Shading mode shows you areas that can’t be reached using 3-axis machining operations

If you’ve not come across these two legends, it breaks down like this.

PowerShape is the front end to the manufacturing and machining process. It combines solid and surface modelling with mesh data handling (including direct integration with scanning hardware) to provide a system that does things that many have never been able to. Why the need for such a tool?

The simple answer is that in the preparation for manufacturing process, particularly in the supply chain, you need to be able to deal with all manner of geometry from good, bad or just plain odd.

Whether that’s repairing surface models or tweaking them, incorporating intricate sculpted decorative forms into a core and cavity — PowerShape is all about getting the job done.

PowerMill on the other hand, handles the process of taking that data and preparing it for machining. Whether that’s machining from a solid billet, for trimming composite parts or machining the perfect surfaces required in the mould and die sector.

PowerMill has always focussed on the complex processes and controlling the complex machines that go with it.

With the Autodesk acquisition, things are looking interesting for this set of tools. There’s huge potential for cross pollination of both technology and business practices with Autodesk’s more traditional, mainstream products — and vice versa.

So shall we take a look at what Autodesk has in store for its first major release since the acquisition and the first under the new banner?

Powershape 2017

The PowerShape user interface remains pretty well thought out and there’s not much in the way of significant changes in the 2017 release cycle.

Perhaps the biggest change is that there’s now integration with Autodesk’s all-encompassing A360 platform.

If you’re not familiar with it, this is the core underlying service and platform that enables many of the cloud-based functions within all of Autodesk’s product offerings, whether that’s Inventor, Fusion, its PLM solutions or even into architectural applications like Revit.

A360 allows you to share data when you need to or indeed, base all of your data storage needs on it. Think of it like a service like Dropbox, but with a lot of file management tools specifically designed for a CAD centric workflow (including integrated viewing and mark-up), more user management and data sharing options. This is now available directly from within both PowerShape and PowerMill.

Whether you use it or not in the context of these systems is entirely up to you, but there’s a solid use case, particularly for sharing data between the programming or design office and the shop floor.

Other user interface updates include the introduction of the View Cube — which Inventor, Fusion (or indeed, almost every other CAD system) users will be familiar with. PowerShape’s comes directly from Inventor, as you’d expect and gives you access to quick view manipulation and standard views.

The final general update is that PowerShape is also starting to see other cross pollination from Autodesk’s other systems. For example, the existing sketching tools (which are perfectly usable) now has the constraints solver (taken from Fusion 360) and gives you all of the predictive sketching tools you’d expect.

It doesn’t replace PowerShape’s existing sketcher (it’s a toggle to switch on or off), but for those looking at the system from the perspective of using alongside another, more mainstream, design system, it’ll make you feel at home right away.

This is only currently available in the solid modelling operations — any surface modelling features will have the older PowerShape sketcher.

Other than this, things remain much the same, clean, with all of the options and operations clearly accessible once you’ve learned how to navigate it.

So let’s move onto the more productive updates for this release.

PowerShape – Diagnostic shading

This is a small update to the existing set of tools for inspecting your CAD geometry, but a significant one — and one which indicates how advanced PowerShape’s tools are at allowing you to take geometry from any source and ensure that you can manufacture it.

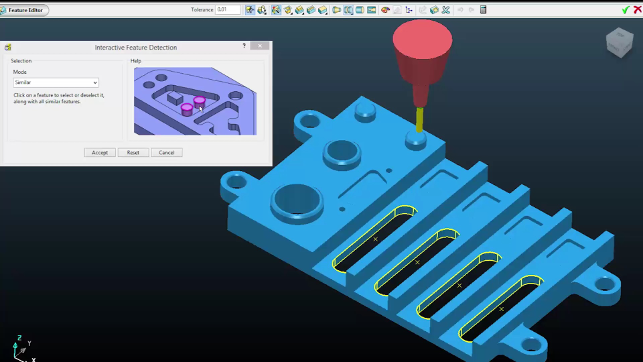

While PowerShape has always had a good set of tools for assessing undercuts in your parts (which is not particularly unique), the 2017 release brings a variant of this called accessibility shading. Whereas undercut shading shows you areas where there’s little or no draft according to a specified vector, accessibility extends this to show areas where a 3-axis machining operation wouldn’t typically be able to reach. The difference is subtle but key.

Accessibility shading will highlight areas where one part of the geometry can’t be reached because of obstructions from other geometry of the part. Figure 1 shows a blisk where the upper portions of each fan blade overhangs the next in the pattern (look at the red tips of each).

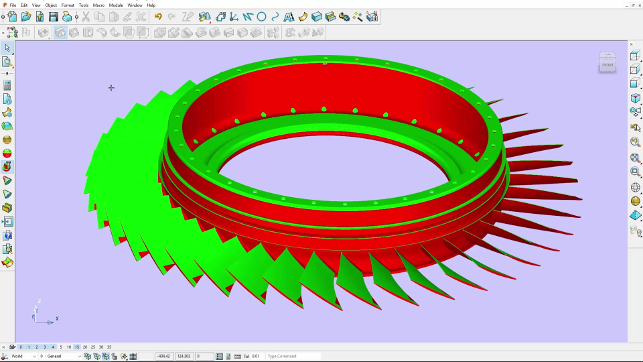

The new Rib Capping command gets you from complex core and cavity features to fully capped off features in seconds

PowerShape – Rib capping

For those working in tooling design, this is perhaps the biggest feature you’ll have seen added to a 3D design system for a good long while — and it relates to that painful process of taking a complex part design and adding the shut-off surfaces for features like ribs or within grill like components.

For those outside of the tooling industry, this is what happens when you build a core and cavity for complex parts — the interior of each of those grill features needs to have a surface built across it, so that the core and cavity create the best possible surface finish for your part.

In other systems and within previous versions of PowerShape, creating these shut-off surfaces is typically a long, drawn out process. While simple parts can be handled by semi-automated features in some systems, when you start to work with large numbers of surfaces and more complex geometry, then it gets very manual indeed — with each needing to be created individually.

To help with this, Autodesk has introduced a new feature called Rib Capping. While it’s a very specific name, don’t get too caught up on what it’s used for — the applications for those extend way beyond ribs — it has implications for electrode design as well.

To use it, you take your part geometry, whether working on the part or the core/cavity directly, you select the top faces (as shown in Figure 2), then the Rib faces (the side geometry). This itself would typically be a complex, time consuming process, but PowerShape has some nifty group flood fill selection tools to help.

Once you’ve got those two sets selected, you choose your surface generation options (there’s control over tangency and rib width) and hit OK.

The system then will generate all of the surfaces you need. It’s lightning fast, taking a matter of seconds to generate (or maybe a minute if you’re working on a ridiculous part) but compared to manually knife and forking each of those surfaces, it’s quick. I mean, really quick.

PowerShape – Spun profile

The penultimate update we’re going to look at for PowerShape is Spun Profile.

This is tied into the updates to PowerMill that bring turning capabilities alongside the systems’ milling capabilities in the 2017 release and help you create the models you need to prepare your geometry for the process.

Spun Profile allows you to take your part model and quickly create a stock model that will encompass the whole of the part geometry. To do this, you define the central axis, then the system ‘spins’ the part and gives you the stock model you need, either for casting, for preparatory stock machining or another process.

While in the turning world, this isn’t too complex, when you start to explore the world of mill/turn machines, then it’ll come in very useful indeed.

PowerShape – Cage morphing & meshes

The last update to PowerShape we’re going to look at relates to PowerShape’s ability to work with a mix of solid, surface and mesh geometry and it’s morphing functions.

For a good many years, PowerShape has been able to work effectively with these three, very different, types of geometry (long before mesh modelling became the latest thing in CAD technology).

At the same time, the system has also had a set of morphing tools that allowed you to grab geometry and push and pull it into shape using drag handles (or indeed, more scientific methods if you’re looking for precise volume values) — but these morphing tools were typically restricted to surface geometry.

What the team has done is allowed you to do the same using a model that mixes up all three geometry types and apply a single morph operation to the whole.

That saves you a lot of time carrying out separate operations for each and also gives you a lot more power and flexibility.

Powermill 2017

Let’s be frank about PowerMill, its reputation in the machining world is one of a world leading system for the machining of complex moulds and dies.

The system has been at the forefront of developments in not only high-speed machining in 3-axis, but also complex 3+2 and simultaneous 5-axis machining. This is where its reputation has been built and still represents its core focus.

That said, there are other applications in the Autodesk advanced manufacturing solutions world that cover the less complex, but just as challenging workflows.

It’s here that systems like FeatureCAM (for turning and production machining) or PartMaker (for mill/turn or Swiss lathe type machine tools) are more appropriate as that’s where they grew up and developed prior to acquisition by Delcam and subsequently, Autodesk.

What we’re starting to see with the 2017 release is that Autodesk are looking to expand PowerMill’s remit to not only cover those advanced use cases, but also to cover the less complex tasks.

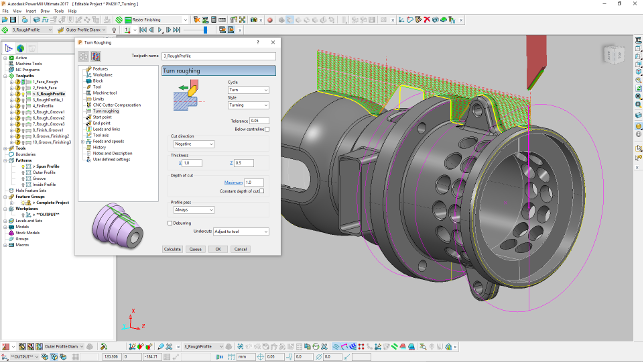

Existing PowerMill users will already know that 2.5 axis machining is starting to make its way into the application. The creation of machining operations based off of simple drawn or 2D geometry is common place and you’ll now be able to do this using tools cross pollinated from FeatureCAM directly inside PowerMill.

This is combined with a set of intelligent tools that allow you to define standard operations and features and have the system do all of the work for you.

It’s presented in a way that will be familiar to PowerMill users and makes the use of such tools quick and efficient — just as it should be.

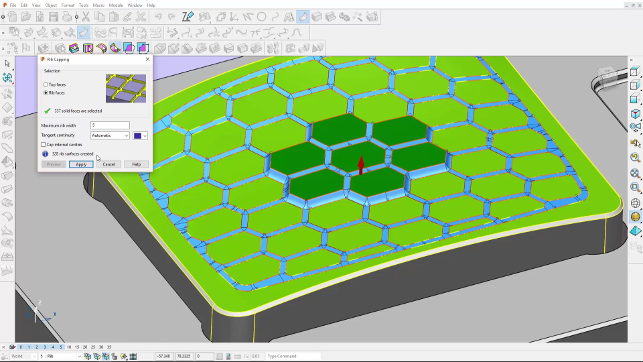

The same is true of turning, which comes to PowerMill for the first time. Again, the core technology here is from FeatureCAM and brings you a set of tools that not only handle routine turning jobs, but also allow you to integrate those operations alongside more complex machining operations (such as 3 or 5 axis operations) and these can be run on the appropriate machine tools — whether that’s individual machine tools for each type or on a single machine capable of both.

As we’ve already discussed, PowerShape now includes the ability to create a Spun Profile and this is typically the starting point.

Once you have the stock model (and profile) in place, it’s then a case of extracting the profiles you need and applying the most appropriate set of turning operations, whether that’s profiling, grooving, bores, part cut off or whatever.

The tooling library has been expanded to include a healthy set of predefine tooling for turning, but of course, you have the ability to create your own standard set of tools as you need.

Once each operation is complete, the system also now includes a simulation capability (referred to as ViewTurn — as opposed to ViewMill) so the operations can be inspected, gauged against your stock model and tweaked as required.

PowerMill 2017 sees the introduction of turning capability, for both regular as well as full integration with PowerMill’s milling technology

Rib machining

Rib machining is another area that’s seen some work done in this release and this comes on two fronts.

In the PowerMill world, the term ‘rib’ refers to a deep, narrow pocket or boss that needs special attention, particularly when the pocket is very deep or similarly, the slot is tall and prone to flexing during the machining process.

The 2017 release fixes an issue where a cutter removing material from a deep, narrow pocket could drop at points of intersection (for various reasons, mostly relating to how the system interprets the geometry). This is now fixed and complex intersections will be handled more easily.

The second rib related update is that it’s possible to add greater control over how such features are machined and the order in which it’s done. Whereas previous releases would give you a brute force approach with little control, the PowerMill 2017 release lets you define how you want such features machined.

For example, to reduce the stress on the part during machining, the system will default to first creating a central pass between the two walls of the part, then take small cuts at each wall to finalise the form.

This greatly reduces the potential for breakages on the machine, as the system removes the large portion of material first (leaving more material close to each feature), then tidies things up to give you the final form.

This approach will always give you more robust operation and hopefully a better surface finish.

PowerMill now includes 2.5 axis machining for those quick jobs, using the same system

Conclusion

This is the first major release of the PowerMill and PowerShape products under the Autodesk brand name and expectations have been high.

After all, the Delcam name was legend amongst the manufacturing community and many wondered how the Autodesk acquisition would effect the future of a set of tools that are core to many organisation’s daily working practices.

The good news is that having sat down with the team in their UK headquarters, it’s pretty clear that the future looks rosy.

The team is still there, still doing its thing and developing a set of tools that advance the cutting edge of manufacturing related technology.

What’s interesting is the approach that the company is taking to the future of its products. It’s pretty clear that rationalisation is coming and the focussing and stripping back of how the products are bundled and sold is testament to that. To my mind, that’s a good thing.

Having a disparate set of software that covered all aspects of machining was good for the company to date, but the future requires that it’s more effective in how the products are developed and how they are supported.

By consolidating on a smaller number of products, development efforts can be concentrated on those and everyone benefits. The latest release is testament to that.

The introduction of both turning and 2.5 axis machining into PowerMill makes huge sense. After all, many organisations are conducting many types of machining operations and manufacturing a wide variety of parts. Traditionally that would require the purchase and licencing of multiple CAM products, which has implications for both cash flow and learning/training.

Yes, there will be some adjustment if you’re an existing user, but the good news is that your existing products are covered and will be supported while this period of transition takes place.

As an example, if you’re a FeatureCAM user, then you’ll get PartMaker bundled into your next update. If you’re a PowerMill user, then you get access to a wider range of tools, covering the basic machining tasks up to the full blow, all singing, all dancing 5-axis, as you need.

It’s also interesting to see how Autodesk is fostering an environment of greater sharing between its different groups.

PowerShape is already benefitting from this with a more powerful sketching for solid modelling operations, access to some of Autodesk’s A360 cloud-sharing platform and a few other neat bits and pieces (such as the ViewCube). I’d predict that we’ll see more of this as things progress in the coming years and everyone will benefit.

Simplified bundles & the move to subscription

As with all of Autodesk’s products, the advanced manufacturing products are in the process of moving to a subscription-based sales model and it’s worth spending a little time exploring what this means for PowerMill and PowerShape users.

There’s no perpetual licence available, everything is sold on the basis of subscription (below we’ve quoted annual prices, but there are multiyear as well as quarterly options too).

There has also been some paring back of options and both now follow Autodesk’s bundle approach, which splits each into three different categories. Let’s explore what that means for each application.

PowerShape Standard (£2,235 annually): This is the entry level surface and solid modelling tools within PowerShape, working with non-native data and standard formats (such as STEP, etc.)

PowerShape Premium (£2,985 annually): This adds the mesh-based tools, electrode design and reverse engineering (for both offline and live scan capture) as well tools to assist with conversion into surface geometry.

PowerShape Ultimate (£3,730 annually): This includes all of the above, but also adds in more specialised tools such as standard libraries and tools for mould-base design as well as electrode design and manufacture.

PowerMill Standard (£5,585 annually): This is the base level package, but even then, includes all of the tools you need for 2.5, 3 axis and 3 + 2 machining. It reflects the state of the machine tool market, with wider spread adoption of more complex 3+2 axis machines and mixed machine tools (Mill/Turn).

PowerMill Premium (£8,385 annually): This extends the Standard offering with the addition of 5-axis milling and robot programming. It also brings you support for native file formats, machine level verification, collision checking and avoidance.

PowerMill Ultimate (£10,245 annually): This is aimed directly at specific vertical market such as aerospace, blade/blisk, port machining, electrode design and machining, rib machining solutions.

| Product | PowerShape & PowerMill |

|---|---|

| Company name | Autodesk |

| Price | See box out below |