Fusion 360 – Recent updates to Fusion 360 are bang on schedule and bring users a wealth of new capabilities at a price point that represents outstanding value for money. Al Dean reports

When we last looked at Autodesk’s cloud-based design and manufacturing system Fusion 360 back in April, we discovered that a lot of work had been done across all areas of the system. These included core modelling updates; the introduction of history-based methods alongside the direct editing tools; new drawing and documentation tools; CAM tools for machining; and the expansion of rendering to provide better results and take advantage of the cloud’s processing capabilities.

So with another quarter of the year out of the way, we think it’s time to dive back into Fusion and take a look at where the system is at now. This overview covers improvements right up to the September release.

External references are now available to insert and maintain links to separate part files, making data management a lot easier

Fusion – Core modelling tools

If you’ve been keeping up to date with Fusion, you’ll be aware that in the last few years it has moved beyond its direct-modelling roots to encompass creating geometry, both with or without history tracking. It has tools for creation and editing of surface geometry (in Patch mode) as well as subdivision surface modelling tools in the form of T-Splines, giving users organic shape creation and editing.

What’s been interesting to watch over recent months is how the tools have become more integrated, with much deeper functionality.

Sketching (for the purposes of creating features) has always been there, but the last few updates have seen more intelligence added with parameterisation and automation. There’s also been an overhaul of the user interface, with greater use of colour already proving very useful.

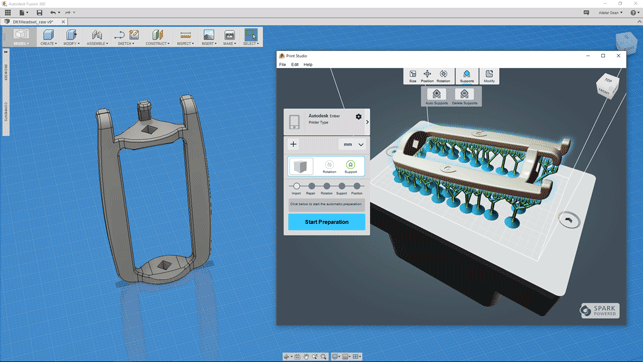

Fusion 360 now connects directly to Autodesk’s Print Studio for file pre-processing for 3D printing

Fusion – Inter documents & Xrefs

For those interested in building more complex assemblies and investigating document reuse, improvements here are perhaps the biggest news. Fusion has been built to work in a multi-body manner: both parts and assemblies are, for all intents and purposes, built in a single file.

Until recently, taking data from one file and inserting it into another was a cut and paste job, with no links between the original and the new instance. With the introduction of external referenced part capability, this changes.

You can search for parts, locate them in the data panel and then click on ‘Insert into Current Design’. This will place a linked instance of that part, which can then be manipulated and assembled, just as you’d expect.

What’s interesting is that the system, due to its inherently managed nature, gives you a couple of additional benefits. First, everything is version managed. Any changes to the source file are quickly flagged up, so you can work through resolving them. Alongside this, you also have the option to load alternative versions of that part.

Links can be broken if necessary, in order to conduct further work on the components, and new versions can be imported (again, the link breaks).

If there’s a caveat, it’s that Fusion 360 takes its lead from traditional desktop design systems, in that you need to consider upfront if a part will be reused, then consciously remember to create it as a separate entity — or save it out separately once it’s needed.

It’s also worth remembering that we’ve said “part”, but the reality is that a single part could contain multiple bodies or, indeed, full assemblies.

Fusion – Machining and fabrication

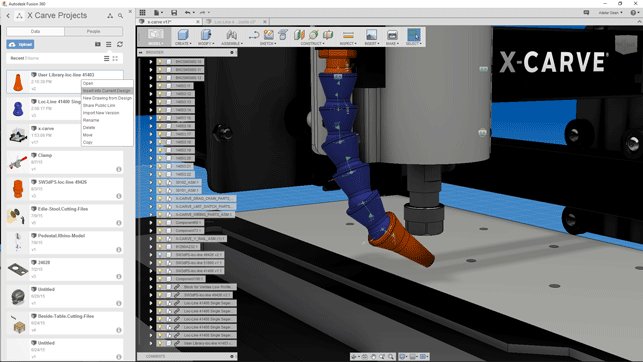

In the last Fusion update we provided, we talked briefly about the introduction of CAM tools in the Fusion environment. This began with 2.5- and 3-axis tools, based on Autodesk’s acquired HSMWorks technology, but the last three months, we have seen existing capabilities expand to include high-speed 3-axis as well as 3+2-axis and 5-axis positional.

The underlying architecture has been revisited, with common posts and tooling libraries available on both Mac and Windows. There’s also the ability to store posts in the cloud, so that they’re shared between installations of your own licence as well as between users.

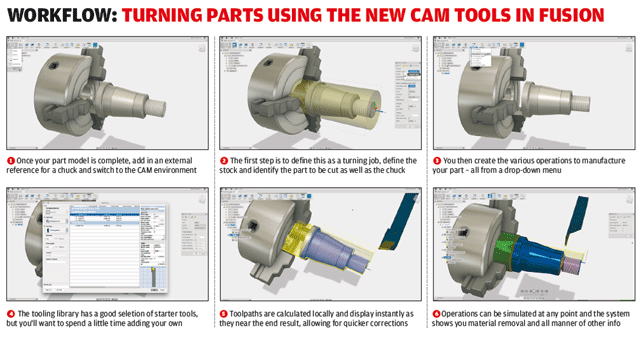

The latest update also brings online something that’s been talked about for a while — namely, the development of a set of tools for programming lathes.

Found under the ‘Turning’ operations, this toolset gives you a range of cutters and operations that support standard lathes. There’s also a bunch of specialised posts for the most common machines and all the tool-path simulation tools you’d expect.

There’s also the option to switch on a preview mode (found in Advanced Settings) for an additional range of fabrication tools, which allow you to program 2D toolpaths for waterjets, laser cutters and plasma cutters.

These cover the basic types of cutting and engraving operations, with full control over kerf width, depth, feed rate and the ability to add tabs to your workpiece. It’s also worth noting that Autodesk has built in a link to its Print Studio application.

This gives you a range of set-up tools not only for Autodesk’s own Ember 3D printer, but also for other machines. If you’re doing 3D printing in house, this is worth a look!

Partnerships and add-ins

Also worth a look are the partnerships that have sprung up between Fusion and other online service providers.

The first, formed earlier this year, involved the integration of McMaster Carr’s standard parts libraries. The last few update cycles have built on this. In addition to McMaster Carr’s library (where parts are found, then dragged/dropped into the model window), you also have direct access to CADenas’ Parts4CAD library.

The difference between the two is that CADenas’ library is more vendor-specific, so you can look up parts by vendor part number, as well as by category and search.

Alongside the parts library enhancements, there have also been a couple of new additions to assist with sourcing components.

The first sees a direct integration between Fusion and Proto Labs’ quotation system. If you’ve not used this before, it’s an automated system where the CAD data is uploaded and, in just 24 hours, you’ll not only have a quote, but also guidance on any areas of concern with regards to design for manufacture.

Proto Labs’ services cover injection-moulded components and machined components from a range of polymers as well as some non-ferrous alloys using both 3-axis and turning processes. It’s now branching out into additive manufacturing following an acquisition of Fineline Prototyping a couple of years ago, with delivery of SLA, sintered plastic and DMLS metal parts (For those in Europe, Proto Labs has just started rolling out its SLA service recently, with the rest to come in 2016).

There’s also an integration to BriteHub, a start-up that offers a range of services that focus on getting RFQs from a range of suppliers (both those from within BriteHub’s own network and those added from your own list of preferred suppliers), managing the quotation process and handling other, related process that extend right into production.

Conclusion

This is a big set of updates to cover – almost every area of Fusion 360 has been updated and enhanced in some way, from the introduction of external references in the core tools, through manufacturing and fabrication, and into new areas such as simulation.

The simulation tools are interesting. Given that CAD vendors have been talking about the proliferation of simulation for nearly a decade and a half, it’s still not what it should be.

Often, the issue is that while vendors want to keep things simple, ‘feature creep’ inevitably means that users end up with a confusing mish-mash of casual simulation tools and expert-level tools.

Autodesk has been through this once before with Inventor and it now seems determined to avoid that situation. Fusion will therefore have a range of tools that are appropriate for designers and engineers, enabling them to perform quick ‘sanity checks’ of their work, rather than full, in-depth simulations. (Interestingly, the company is planning to support more in-depth simulation, with an initiative called SimStudio, but it intends to tap into Fusion’s ease of use to make this much simpler for its target audience).

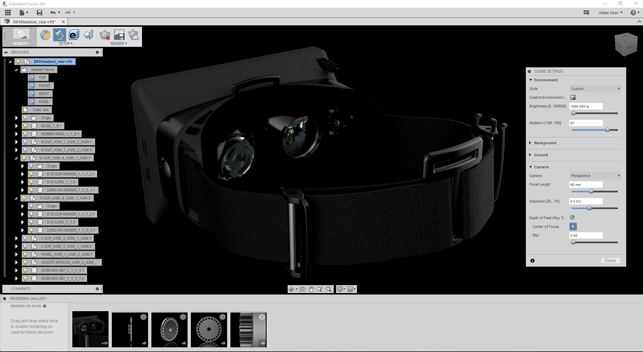

Though we’ve not discussed rendering in this review, there’s been a few additions to the tools, most notably, the ability to use your own HDR image maps as lighting environments

On the whole, Fusion is progressing well. What’s interesting, apart from the technology itself, is how open Autodesk has been about its future plans, publishing a roadmap with firm delivery dates.

And so far, it’s doing a bang-on job of delivering against them. The introduction of simulation capabilities in the latest update makes the value proposition for Fusion even more appealing.

Remember, this will cost just $25 a month — for everything. I’m sure the price won’t stay that low forever. Users will almost certainly see the reappearance of the higher price-point Fusion Ultimate offering at some point. But for now, what you get, across both Windows and Mac, for that sort of cash, is nothing short of mind-boggling.

If there’s a cause for concern, it’s that users outside of North America are getting less attention from Autodesk. It’s a small point, but something that I think the vendor needs to consider. McMaster Carr, for example, is a North American supplier, with very little presence in Europe.

Likewise, the Proto Labs connection is currently only available in the US — it won’t even be activated in installs outside of that region, and according to Proto Labs in Europe, there are no plans to change this. BriteHub, meanwhile, is available to all, but the service is US-focused, with no suppliers I could spot outside of those borders.

That point aside, it has been a good quarter for Fusion users across the board. Considering the moves Autodesk has made to shift everything that was previously included only in the Ultimate bundle into the base-level offering (and everything we’ve discussed here is in there, too), the price of $25 dollars per user, per month is an absolute steal.

When you consider the CAM tools alone, that represents outstanding value and, if you’ve got the hardware in house, that could be sufficient justification by itself for exploring Fusion 360’s potential.

http://www.autodesk.com/products/fusion-360/overview

autodesk.com/fusion360

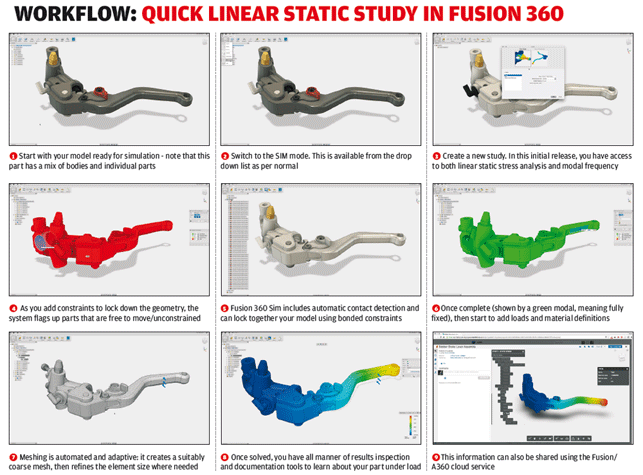

Fusion gets simulation: Linear statics and modal to start

As DEVELOP3D went to press, Autodesk was in the process of rolling out its September update, in line with its monthly update cycle. This is a big one. For some time, Autodesk has been promising to bring simulation tools to Fusion 360 – and it’s now starting to deliver.

Of course, there has been motion simulation in Fusion for around a year now, but this is the first time that anything based on finite element methods has been seen, bringing linear static and modal analysis tools into the system.

These capabilities are built on the same FEA solver that’s been included in Inventor Professional for some time (itself based on the Plassotech technology Autodesk acquired back in 2007). The idea here is to provide simulation for designers and engineers, rather than a fully fledged FEA system.

As a result, the process is packed out with intelligent use of automation where appropriate, particularly in the areas of contact detection and meshing. The user interface guides you through the process, from CAD geometry to completed solve and results.

The tools are found in their own ‘mode’ called ‘Sim’, which sits alongside the Model, Sculpt and Patch modes. They use the familiar Study method that allows users to conduct multiple studies in the same file.

To kick off a new study, you need to first define constraints. Here, Autodesk has incorporated a colour-coding method, which identifies which parts are free to move and need to be locked out. This is particularly important, considering Fusion’s multi-body nature.

As you add in constraints, the system shades the model in colours between red (indicating those parts that are entirely free to move) to green (those that are fixed and unable to move).

As mentioned, there’s some automation here: users can have the system automatically find areas of contact between freely moving bodies or parts and lock them down with a bonded contact. This can be overridden, if that’s your preference, but it offers a shortcut that can get you where you need to be, very quickly.

Once a model is all green, you add in the loads that are acting on your model, define the material (the system will pick up material definitions from the model, but this can also be overridden) and start the meshing process.

Again, automation and intelligence is useful here and the sim tools in Fusion feature the same adaptive meshing tools found in Desktop Inventor and other systems. These ensure that a model is high fidelity where needed (by lowering the element size), but keeps it at a reasonable level where it isn’t.

Once everything’s in place, you hit solve. At present, Fusion’s sim tools are local only – all of the computation is done on your local machine. There’s cloud computation coming in a couple of months’ time, but for this type of work, I’d imagine local compute is perfect.

Once the solve is complete, you then have a good range of results inspection tools, the usual fringe-plotting and animation tools, as well as automatic report output, if that’s your bag.

Of course, creating a report is one thing, but being able to share the results of your studies is also key and, considering Fusion’s inherently collaborative approach, this is worth exploring.

First, if you’re sharing access to your projects, those with read access will be able to see any of the results of the simulation, but their client won’t automatically download all of the data. That makes sense to me.

Second, and perhaps more usefully, all of the results information is available through the project management portions of Fusion, which are based on Autodesk’s A360 cloud service, so team members will be able to view, inspect and mark up the simulation results as well.

Simulation looks set to get a lot more attention in coming updates. Thermal radiation studies should come online soon and Autodesk is looking to introduce multi-physics studies, starting with thermal stress.

Further out, there’ll be more physics added as appropriate – and maybe even the Nastran solver, too.

| Product | Fusion 360 |

|---|---|

| Company name | Autodesk |

| Price | $300 per year |