When Objet Geometries launched the Connex500 earlier this year, it introduced an entirely new concept to the 3D printing sector – the ability to produce a model with different mechanical properties.

The machine worked by mixing two master materials in different ratios on the fly to create any combination of rubberlike, flexible and rigid parts with different visual appearances and shore hardnesses. Most importantly though it was possible to do this in a single build.

The combination of rubberlike, flexible material and rigid material allows users to print models for a wide variety of applications

The younger sibling

Objet has now introduced a new machine, the Connex350, which features exactly the same core technology, but in a more compact unit, with a smaller build tray size (350 x 350 x 200mm compared to 500 x 400 x 200mm). This reduction in size is also reflected in the price of the system, making it much more affordable for a wide range of users.

Having seen the Connex350 in action at Dassault Systèmes’ recent DEVCON event at its headquarters in Paris, the machine looks very office friendly. Around the size of a standard photocopier, but much more stylish in its appearance, the office friendly credentials are earned through the use of completely sealed material cartridges. These are loaded up with ease and getting the machine ready to print doesn’t take a great deal of effort.

As with the Connex500, the quality of the models created with the Connex350 are amazing. Very fine layers of 0.016mm thicknesses are combined with high-resolution printing in the X and Y directions to deliver models of impressively fine detail. And by taking advantage of the many material choices on offer it can be used to generate models with the required look and feel of actual end products. The combination of rubberlike, flexible material and rigid material allows users to print models for a wide variety of applications, from coating and shock absorbers to living hinges and gaskets – and it excels at replicating the feel and tactile response of over moulded or multi-stage injection moulded components – something which is very time consuming and labour intensive to prototype using vacuum casting.

With a smaller build tray size of 350 x 350 x 200mm the office friendly Connex350 is the younger sibling of the Connex500

Conclusion

The decision to acquire an in-house rapid prototyping technology is a choice that most design-led organisations don’t take lightly. After all, investing in a machine can be expensive, particularly when you consider the on-going costs of maintenance and materials supply. Alongside the cash costs, there’s also the constant nagging thought that by investing into a single technology, you’re excluding others – putting all your eggs in one proverbial rapid prototyped basket. This is exactly why the Connex350 is so appealing. In comparison to the many other office-friendly 3D printing devices, it offers increible flexibility in terms of the mechanical properties of builds. And as such, if you are evaluating these tools, then it should certainly be flagged up for further investigation

Integrating Rapid prototyping and CAD

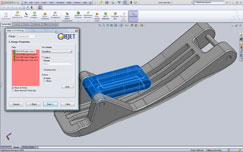

Helping bring the worlds of 3D design and rapid prototyping closer together, Objet has recently launched a number of ‘CADMatrix’ plug-ins that enable users to control builds directly from within their 3D design system.

Objet has recently launched a number of ‘CADMatrix’ plug-ins that enable users to control builds directly from within their 3D design system.

There are plug-ins for SolidWorks (pictured left), Inventor and Pro/Engineer), and having given the SolidWorks and Inventor versions a test drive, it’s clear that they can greatly assist those working with these machines in house.

The plug-ins allow users to select parts or assemblies, materials, the machine to build on, coatings (to achieve a soft touch on a rigid material), and then have the system generate the required file for set-up and printing. The system then creates STLs from the CAD geometry to the required accuracy and even provides an HTML report when it’s complete, so users know which parts are going to be built and which materials need to be loaded into the machine.

| Product | Connex350 |

|---|---|

| Company name | Objet Geometries |

| Price | on application |