Chain Reaction

With a bicycle stolen almost once every minute in the UK alone, and thieves becoming more ingenious, a lock for your two-wheeler needs to be Schwarzenegger-tough.

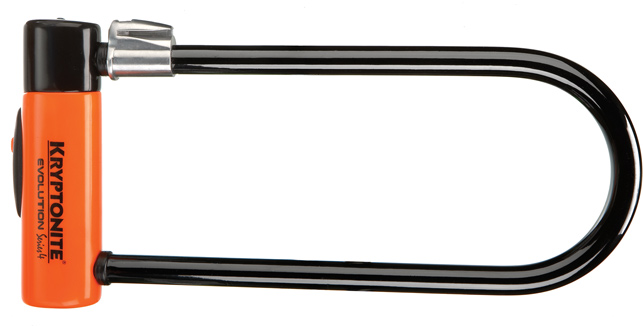

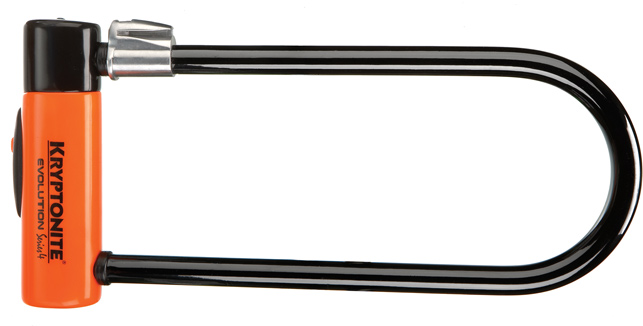

Step up the Kryptonite Evolution U-lock: designed to thwart the latest theft methods (generally brute force, cutting tools and leverage), and to fit the strict standards of the European certification criteria.

The Evolution 4 is designed to fit the strict European certification criteria

“The European market is different from the US in that third-party testing and certification is essential to the commercialisation of a bicycle security product,” says category product manager Don Warren.

“We used the performance criteria from multiple EU countries’ testing organisations to create the design standard for this particular lock.

“Designing a lock from this perspective yielded a number of engineering challenges resolved through the specific form-factor of this lock.”

The familiar U-lock shape is now more oval, giving the product more security than in previous designs when testing ‘pull strength’, a measure of how much pressure is required to pull the D-shackle out of the crossbar

Having discussed balancing the security features needed with the issue of product price point targets, concept sketches are drawn up and the modelling begins in SolidWorks.

“It was fairly simple for us to use Solidworks to create a hybrid of several existing designs and accelerate the design timing associated with this new generation product,” says Rob Zuraski, Kryptonite’s director of engineering and product development.

“At various points during the design process we used the feature which enabled a dynamic sweep of cross sections of the design through the assembly. This allowed our designers and manufacturing engineers to quickly identify potential vulnerabilities in the design and resolve them before going to tooling.”

Kryptonite’s internal physical prototyping proves out the design, as well as establishing a benchmark for initial tooling samples, where CAMWorks is used to help prepare the model for manufacture.

The lock even has an element of sustainable design to it, with it intended to be a fully serviceable lock and not a throw-away commodity.

The finished product is a robust lock, tough enough to give your bike a glimmer of hope against the roving hoards of bike thieves that roam the streets of our cities.

Enemy at the gates

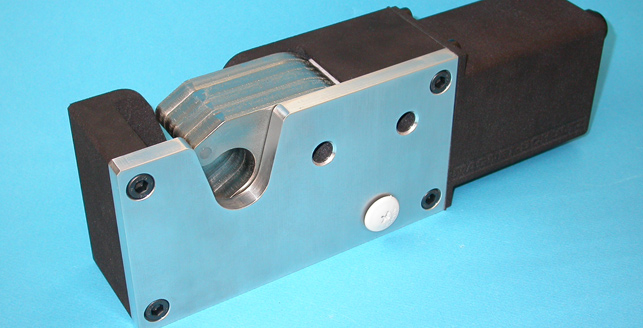

Magnet Schultz is an expert when it comes to all things electromagnetic, putting the company in an ideal position when it comes to automated lockdowns on an industrial scale.

Its latest design for a large, flexible, gate locking mechanism is just what you need if you have an industrial unit or government building you want to keep secure.

Magnet Schultz turned to rapid prototyping in order to have a working prototype available to show prospective customers

In typical automated gate assemblies, if one gate drops in height through hinge wear the resulting misalignment means that the security gate is no longer secure. With this new design a misalignment of up to 15mm can be accommodated, meaning there’s less chance of a problem occurring and a reduction in the need for service and support

Product specialist Tim Lloyd explains that the new product was designed to cope with wear and tear, have lasting security, and be able to withstand attack – important if you’ve just invested around £20,000 on a new security gate.

“We came up with three variations on a theme and gave the outline information to our design engineer Robert Sam and got him to do some initial feasibility studies in the CAD system,” explains Tim.

Producing working models in Autodesk Inventor, they narrowed it down to a single design, which was assessed then put through a series of stress and force calculations using the 3D model in Inventor.

“When we’re putting together an initial idea of how much it’s going to hold and whatever the locking devices need to be, any type of stresses or safety factors we can work out through Inventor is a starting point,” says Robert Sam.

This was the first time that Magnet Schultz turned to rapid prototyping in order to have a working prototype available to show prospective customers. Using the nearby bureau 3TRP the parts were built in a Duraform material within the week and actually made up part of the fully working lock.

The 3D model was also transferred into Maxwell Render to provide realistic renders that could be used in the marketing material helping to ‘lock-up’ customers before the parts had even been sent to manufacture.

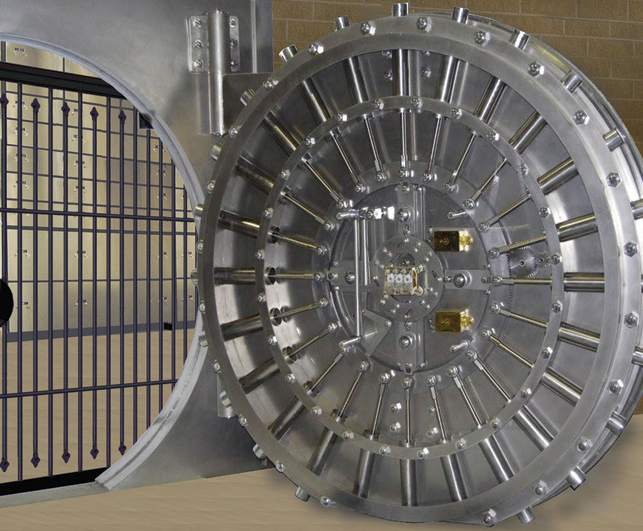

It’s in the bank

In the movies very few things beat the tension of a bank heist, whether it’s the delicate, fingertip, cracking of the safe’s code, or simply piling up the explosives and letting rip. Keeping out the villains nothing quite screams ‘secure’ as a big, shiny, round bank vault door that weighs over 4,000kg.

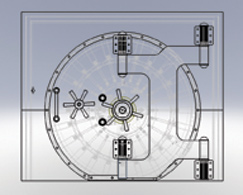

Big, shiny, round and weighing in at over 4,000kg

Aside from overall security, the two most important considerations in designing a massive vault door are a tight fit and the ability to get out in case of an accidental lock in.

Vault Structures is one of the few manufacturers building security facilities on this scale and the company’s latest design is the 14-inch thick, 4,082kg, VSI 360 vault door. The styling is a nostalgic nod to the early twentieth century safes; a period when bank robbers clung to the sides of automobiles, and bankers sat behind counters wearing little green visors.

Thankfully for your gold bullion the technology has been completely updated. The vault uses modern metals, multiple bolts and re-lockers all piston driven from the central lock, fitting it tight into the frame.

“We designed this door so it would only have a 3/16 of an inch gap around its circumference,” says design engineer Sara Cheney. “That’s a very tight gap for such a large door, providing maximum security.”

The design was modelled in SolidWorks to ensure dimensions were accurate, with SolidWorks Simulation being used for strength testing before it went into production. By doing so the design team managed to design and test the door roughly 70 percent faster than previously, saving them $150,000 in reduced prototyping costs.

Vault Structures also depends on SolidWorks Workgroup PDM to maintain design version control and manage its vault designs throughout their entire lifecycles.

“If security is job number one, longevity and durability are next in line,” continues Sara. “Our products are built to last hundreds of years. So it’s absolutely critical for us to keep an accurate, detailed history of parts, designs, and modifications.”

However, with such a retro aesthetic it’s hard not to reach for the stethoscope, drill and blowtorch in an attempt to recreate some movie classics.

www.vaultstructures.com

From bike locks to bank vaults, DEVELOP3D gets security conscious