Sunreef Yachts navigate new design approaches, buoyed up by simulation and optimisation technologies

When Francis Lapp founded Sunreef Yachts in 2002, he was taking a gamble. He firmly believed that many buyers of luxury catamarans would value living space, high-quality materials and ergonomics over speed and power – but would his bet pay off?

After all, as he points out, privately owned luxury catamarans were nonexistent back then. “But I sensed that tastes had evolved. Many yacht owners come to Sunreef because they want to switch from a monohull vessel to a catamaran, because a catamaran is more stable due to its double hull,” he explains.

“Moreover, it can provide a more ample living space, providing a better sense of conviviality and community than narrower, longer yachts.”

Luxury, he adds, also means being able to venture where yachts cannot go: “By this, I mean [that] sailing around the world with a catamaran is feasible, whereas with a yacht – even a big yacht – it’s not always the case, because of the yacht’s instability and lack of autonomy.”

In effect, a catamaran has more autonomy, “because there is less hull friction in the water, so less drag and better fuel consumption. Just think, on an 18-metre catamaran, we can cross the Atlantic Ocean on one full tank of fuel.

This is not necessarily possible with a 40- or 50-metre classic yacht.”

Trust and cooperation

Sunreef’s high-end luxury products are built for the world’s most demanding and discerning customers, who expect a product that delivers the best in design, safety and luxury.

It’s no easy task to combine fresh design, seaworthiness and customisation with other important aspects such as energy efficiency, reliability and high performance.

All this has to be factored in when the company begins to design a new model – and understanding the boat’s hull plays a crucial role, according to Sunreef Yachts’ design office director, Piotr Hinczewski.

“Coming up with an appealing, easily customisable and seaworthy product is only possible when you have a powerful tool for design and simulation.

It’s critical for our customers that we virtually verify the 3D design model of the vessel,” he says.

“The shape of the hull depends on many small details, which we can modify to achieve different aspects, like high energy efficiency or high speed in the case of a motor boat, while still being easy to navigate. All these details need to be taken into account in the design and illustrated as the design progresses.”

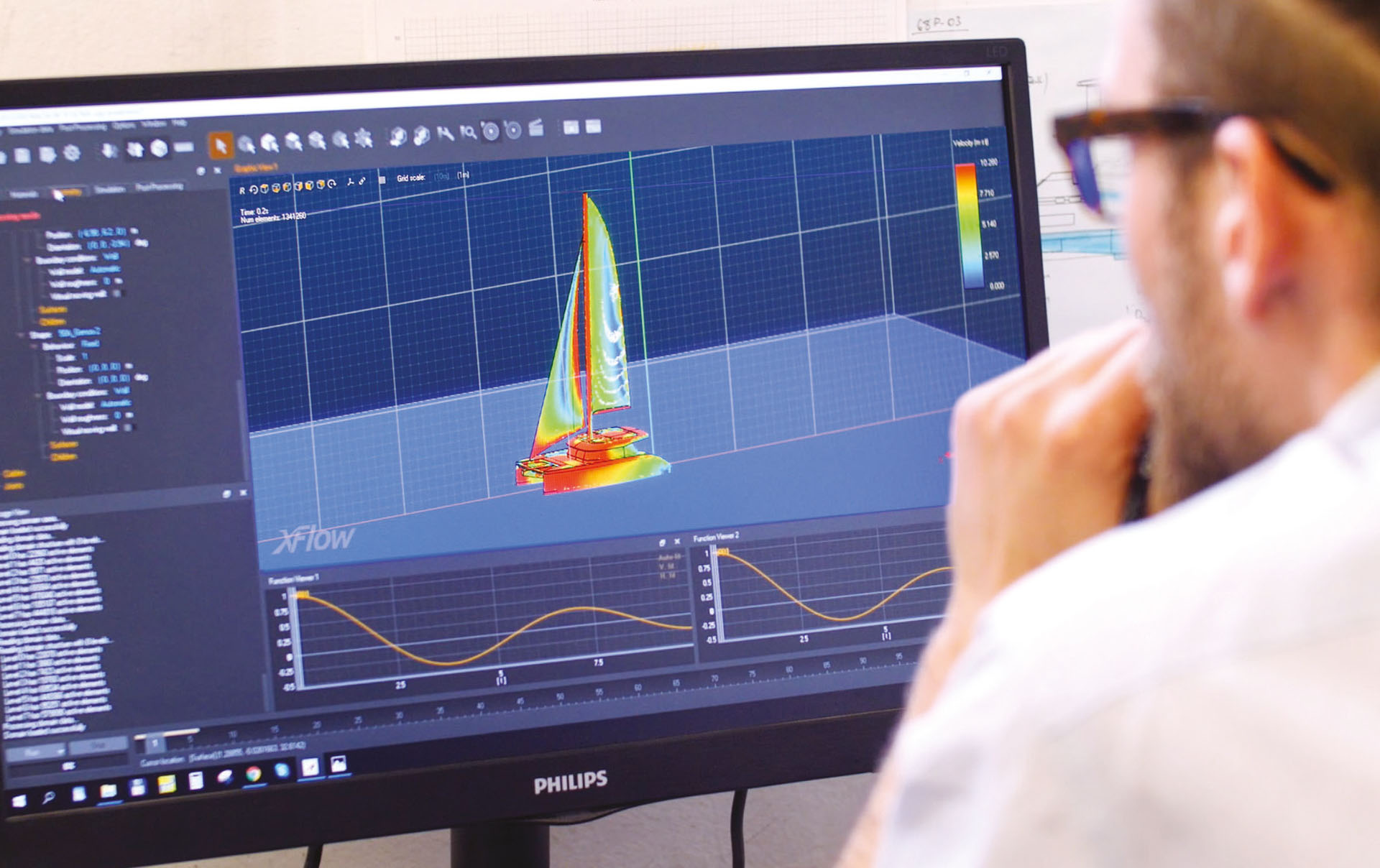

To achieve this, Sunreef Yachts implemented Dassault Systèmes Solidworks design applications and Simulia XFlow to digitally simulate and verify the vessel’s seaworthiness before finalising a design.

We perform computational fluid dynamics analyses with Simulia XFlow to see how the boat will behave. And if we want to investigate a new design idea, we develop the concept in Simulia XFlow, which checks the boat’s aerodynamics and hydrodynamics through digital simulations,” says Hinczewski.

In order to correctly design or tune the propulsion system, he continues, the company needs the hull resistance curve to be derived from XFlow: “This defines the power required to propel the yacht, including both hydrodynamic and air resistance for various speeds and environmental conditions.

With this information, we can choose the correct engine, match up the best propellers and select the sail plan, as the software can simulate close to real yacht conditions.”

For example, for a 40- foot motor boat with a high-performing engine, Sunreef Yachts needs a shape that will allow the vessel to go fast. With a 60-foot sailboat, by contrast, speed may not be as important, so the hull shape will be completely different.

“Thanks to Simulia XFlow, we can test several scenarios – different shapes, speeds, sea condition – and get our results quickly,” says Hinczewski. “Based on the results, we come up with an attractive shape for optimum seaworthiness and fuel consumption. And if the client wants to install a new feature, we need to make sure it doesn’t adversely impact the boat’s speed or navigability.”

Breakthrough in shape optimisation

Sunreef Yachts prides itself in building very comfortable boats that include high-end luxury equipment.

Consequently, much attention is given to weight. In order to meet the desired performance benchmarks, shape optimisation is a key success factor for achieving the best hydrodynamics and energy efficiency. It also leads to a better understanding of engine choice, fuel efficiency and possible sail options.

According to Francis Lapp, there’s also a market for large, 50- to 60-metre catamarans that are ecologically friendly, in that they use electricity or solar power electric and include ecofriendly furnishings.

“We are currently experimenting with a revolutionary solar panel that will be directly integrated in the hull or mast,” he reports.

For these reasons, he says, Sunreef Yachts will continue to use Solidworks and Simulia XFlow applications, especially to build bigger boats.

“They are key to our future development,” Hinczewski confirms.

Instead of simply selling boats, Sunreef Yachts promotes a philosophy that focuses on an exceptional sailing experience, ample living areas and quality after-sales services.

“We build close relationships between the shipyard and client, because this creates an overall sense of family and that is our trademark,” Lapp concludes.