Using VR, BPA is able to visualise the machinery virtually, animate various mechanisms and test ergonomics

For makers of food and care products, the safe delivery of goods that stock the shelves of supermarkets, pharmacies and customers’ homes around the world begins on an automated factory line.

It’s here that products are individually picked, wrapped, sealed, boxed, labelled and readied for shipment. Whether the product is a loaf of bread or medicines for children, the top priorities when it comes to packaging are quality, hygiene and consistency.

Founded in 1980, BluePrint Automation (BPA) is a leader in the kinds of machines that deliver high-throughput packaging automation. The company provides one-ofa-kind, turnkey systems to facilities in over 30 countries.

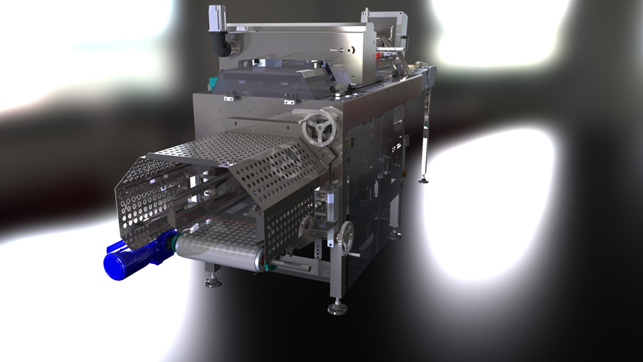

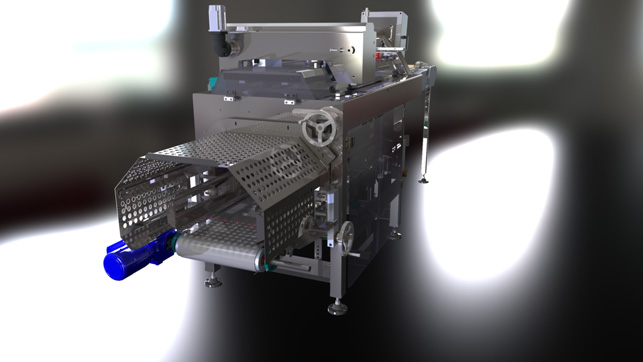

The 3D mechanical designs of these machines are highly complex, with each machine typically consisting of over 1,000 unique parts, a combination of off-the-shelf modules and custom mechanisms that the company designs itself. By matching its modular systems to specific customer needs, BluePrint Automation creates tailor-made solutions for optimal output.

While the packing machine itself is often at the core of the design, there’s also all the other equipment on the line that needs to be custom-designed for every job. These huge, interlinking set-ups can take up entire factory floors.

“Last year, we had a customer come look at one of the machines, and they said, ‘Wow, that’s much bigger than I thought it would be!’” recalls BPA’s vice president of engineering Chung-Chee Tai, who is based in the company’s Virginia, US design office. “That’s when I thought that if we had virtual reality, then that would be really useful. There wouldn’t be surprises like that.”

Virtual reality (VR), he decided, would enable the company to give a human scale to its models, offering customers a sense of how tall or how long a machine might be.

“People just don’t realise how big a machine can be sometimes,” says Tai.

The designs in SolidWorks are highly complex, with each machine typically consisting of over 1,000 unique parts

BluePrint Automation – avoiding changes

Because of the scales involved, and the need for machines to integrate with each other, it’s critically important to get everything right first time. It can be extremely costly to adjust a design once a machine’s on site.

BPA’s 3D CAD models are designed in SolidWorks and have long been of benefit to designers. More recently, the addition of VR for the design and engineering teams has helped them to spot clashes and problems earlier on in the design phase.

Somewhat surprisingly, moving the SolidWorks data into VR is done using free software – the AMD Radeon ProRender add-in for SolidWorks, Unreal Engine 4.17, and AMD Radeon ProRender Game Engine Importer for Unreal.

Using a Dell Precision 5820 workstation, equipped with an AMD Radeon Pro WX 9100 graphics card, BPA creates photorealistic renderings of its CAD models within SolidWorks, using Radeon ProRender. The rendered scene is then exported as a transportable format.

Using the Radeon ProRender Game Engine Importer, BPA can then import the scene into Epic Games’ Unreal Engine.

Templates in Unreal Engine help to streamline the process of building a VR experience with the imported CAD data.

Once the model is in VR, BluePrint Automation is able to visualise the machinery virtually, animate various mechanisms and test ergonomics, reviewing the engineering before anything is built, saving time and money.

Previously, BluePrint Automation shared images of CAD models in online customer meetings via Skype, but Tai says that this method falls short when it comes to allowing enough control over what the customer can see. That means there’s room for errors to creep in.

“With VR you can take your time, look at what you want to look at and focus on that,” he explains.

Sales sees potential

It wasn’t long before other areas of the business wanted to get involved. “Our sales department saw the tool and they wanted to take [the results] outside for show and tell. It wasn’t exactly planned, but it was a good outcome,” laughs Tai.

BluePrint Automation now uses its VR experience to win over customers with new designs and generate new sales at industry shows, where showcasing a physical machine can be an expensive proposition.

“It’s not just eye candy,” insists BluePrint Automation mechanical engineering clerk Katie Hildebrandt, speaking of BPA’s use of VR at a recent industry event. “It’s serving a purpose and I feel that everyone who came to our booth saw that.”

She continues: “Some were really sceptical until I showed them all the mistakes you could catch before assembling and manufacturing and products. It’s good for safety analysis, too, such as showing areas where it wouldn’t be safe to put your hands.”

The next step for BPA’s VR adoption is back in the design studio, where its engineers are looking to use the technology to optimise key features, such as operability and serviceability, packing even more insight into the early design phase.

BluePrint Automation adds VR to CAD in its design of packaging machinery

Default