The Raspberry Pi Zero W comes with three interchangeable white lids

The Raspberry Pi is quite simply a phenomenon. Since its launch in 2012, this credit card sized PCB, recognised as the world’s smallest computer, has found its way into all sorts of applications from motorised skateboards, digital signage through to sensors on the international space station.

With total sales now topping 14 million, it has not only become the best-selling British computer of all time, but also the third most successful platform after the PC and Mac. Pretty impressive for a small team of Cambridge University computer scientists and academics who hoped to get kids interested in coding and had modest ambitions of selling a few thousand units.

Today the Raspberry Pi Foundation, a UK charity, has a user group that is vast and boasts a vibrant online community who use the Pi in not only educational but also hobbyist and industrial settings.

Affordability and accessibility have always been the key aims of the Foundation. In 2015 it launched the Pi Zero; its smallest entry level computer (half the size of a Model A+) priced at just $5/£4. Such was its popularity that, when placed as a giveaway on the front cover of the December 2015 edition of The MagPi magazine, it caused a national stampede within newsagents.

The official Raspberry Pi 3 case offers maximum accessibility to the electronics inside

Raspberry Pi – Latest product in the range

Earlier this year, on its fifth anniversary, the Foundation launched the next product in its range – the Pi Zero W, priced at $10 and with more functions such as Bluetooth and wireless connectivity. It launched with a brand new official case designed by the same team who worked with the Foundation on its original Pi case: Kinneir Dufort.

Back in 2013, Eben Upton, Raspberry Pi’s founder along with Gordon Hollingworth, director of software, had a vision to create an affordable case that not only served to protect the Pi, but to be a truly beautiful and well thought out product.

There were, as expected, many unofficial 3D printed cases, for which files are available online for others to recreate. However, as many users tend not to have readily available access to a 3D printer, the Foundation enlisted the help of Bristol-based design consultancy Kinneir Dufort, to help create the first official injection-moulded Pi case.

Whereas most cases are designed to lock away electronics, this new design veered far from the traditional. Rather than acting as an enclosure, clever clip-together panels allow users to get hands on with the electronics and experiment.

“One thing we learned early in the project is that everyone associates the Raspberry Pi with a green PCB and we really liked that. So one thought we had, was to let the case take a back seat to offer maximum visibility and access to the electronics,” says John Cowan-Hughes, senior industrial designer at Kinneir Dufort.

With a clear vision of how the case was to act, it also needed to be universally appealing to the Pi’s diverse user group. “If you design something for school kids it has to look a particular way to be appealing, yet you can’t alienate the home entertainment users who are on the other end of the spectrum. So, it was a really interesting design challenge and that affected everything from the colours to how minimal the design is,” comments Cowan-Hughes.

Kinneir Dufort’s ideas for the case fell into three categories: visibility of the electronics; accessibility of what’s within to encourage experimentation; and classic product design for consumer use.

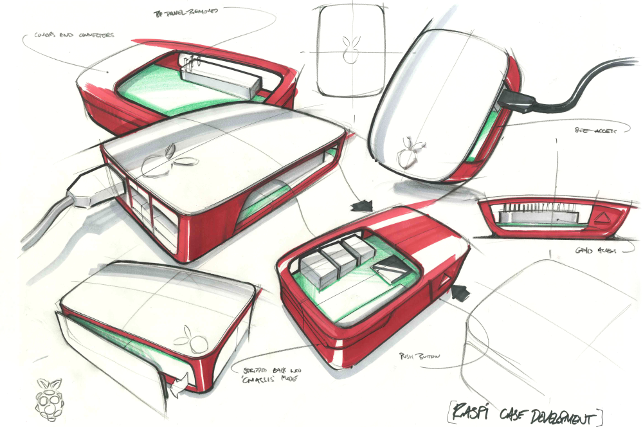

Around 40 original ideas were sketched out on paper in a variety of colours and variations. Then and having received the Pi electronics as a CAD file, the Kinneir Dufort design team carried out the next phase, known as ‘sketch CAD’ in SolidWorks.

“It’s still CAD but it’s not production data – we are sketching with the CAD because it is quite defined in terms of its parameters,” describes Cowan-Hughes. “Then we created many rendered visuals in Keyshot to really bring the concepts to life.”

Having presented these many ideas to the Pi team, a concept was chosen from each of the three categories. Once refined in CAD, 3D prints were produced using Kinneir Dufort’s in-house Objet machine.

Following input from the Pi team, the models underwent further development, including the creation of high quality prototypes. These were produced using vacuum casting to show the functional and visual aspects of the models.

“They were still open to the three different avenues right through the development process but I think the construct concept, which is the one that focused on accessibility, was always the clear winner,” says Cowan-Hughes.

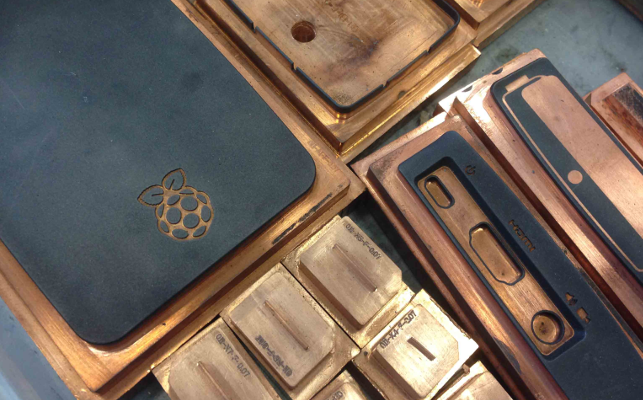

Despite a few hiccups with the tool maker, causing delays in production and resulting in a move to the plastic injection moulding company T-Zero in the West Midlands, the case eventually launched in 2015. It was an instant hit, selling one million units in its first year globally.

Raspberry Pi case development by Kinneir Dufort

New product, new case

Two years later, with the product range expanding to include Pi Zero W, The Raspberry Pi Foundation were clear about the importance of this new case resonating the same family resemblance in its industrial design as the original.

According to Cowan-Hughes, the new case followed here-or-there the same design process as the original; this time, however, with far less concepts.

Like its predecessor, the PCB is framed in a raspberry coloured red base with white side panels. However, and in line with the core Pi value of experimentation, Kinneir Dufort designed three interchangeable white lids for the product.

Rather than simply one lid, these allow the user to adapt the case to suit their needs. Firstly, a simple and blank lid, in line with the original. Secondly, with an aperture to allow access to the GPIO pins along the edge of the PCB. Lastly, a lid with both aperture and mounting point for a camera.

For consistency and added consumer benefit, all three cases also include a short camera adapter flexi, plus a set of rubber feet to avoid sliding off any surface.

Details in the tooling, which wasn’t a smooth process for the first case

“The lids are almost as easy to get into as Tupperware. Literally take the lid off and it doesn’t alienate the user or block them from the electronics,” says Cowan-Hughes.

So with a validated and trusted manufacturing partner, combined with the design vision of Kinneir Dufort taking the product from initial sketch right through to production, the process ran smoothly; much more so than the first time.

The Raspberry Pi Zero W cases launched earlier this year and it almost goes without saying that, much like everything Raspberry Pi does, they have been a huge hit with users.