A project to update Britain’s temporary road signs presented a good opportunity to divert design work in a better direction for pedestrians and workers alike. Designer Ross Atkin spoke with Stephen Holmes about creating more inclusive designs from recycled materials

They’re hidden in plain sight, part of the everyday street furniture that you might pass by without noticing, but Britain’s temporary road signs are evolving. Working with PF Cusack, a major supplier of road traffic management products, designer Ross Atkin has developed a new Highway Sign System that offers benefits for everyone that uses and works on the roads.

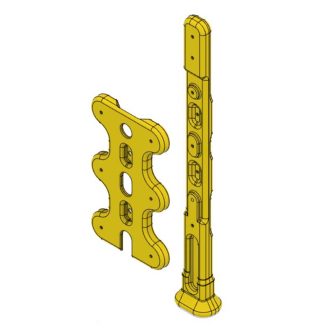

Compared with traditional metal A-frames anchored by sandbags that hold up temporary signs, the new design is made entirely from plastic, including its injection-moulded, recycled base.

Eliminating the need to use heavy sandbags is a big bonus from the get-go. These sandbags need to be filled, any spillage must be managed, and they must be transported from place to place. Getting rid of them means that vehicles used to transport signs can accommodate more units and these units also feature hand grips that make possible safer lifting and manoeuvring.

Atkin’s experience in designing signage for visually impaired people also impacted the project. “Many years ago, I worked on something called Sight Line, which involved a whole load of small tweaks to the barriers and signs placed around roadworks to make them much easier to navigate, primarily for people with sight loss, but also other disabled people,” he explains, speaking from his studio in Hackney, East London.

Sight Line was deployed on London’s streets by a construction firm for a trial period. Impressed by the results, they reported their findings to PF Cusack.

With that connection made, Atkin was soon asked by PF Cusack to explore a new design for temporary road signs, a regular feature on the pavements and streets of the UK capital.

According to Atkin, this is a good example of a marginally more expensive product gaining adoption because of changing circumstances. The official body that oversees London’s roads was clear that it wanted to ban sandbags from being used to weigh down signs. “So everyone could see a future where sandbags were banned, and that this product was the thing that would be used instead,” he says.

Base considerations

Without sandbags, Atkin faced the design challenge of creating a base that could stand up to forces such as strong winds. The new base, which weighs in at 27kg, is made from the weighted bases of recycled traffic cones and road barriers, which are themselves made from recycled PVC carpet tiles and other post-consumer waste.

The neat footprint of the base, meanwhile, is defined by the Presma rotary injection moulding machine used to manufacture such hefty parts. Atkin jokes that it was strange having to maximise the amount of material being used in an injection moulded part, instead of keeping it to the minimum.

The rotary injection moulding machine allows for multiple tools to be filled, revolving on a carousel post-injection, allowing twelve of the heavy bases to be produced in a faster cycle time. It’s a process that Atkin refers to as ‘high-entropy recycling’.

“It’s quite tolerant of different kinds of materials”, he adds, explaining that the material isn’t super dependable, as it lacks the consistent mechanical properties of virgin plastic, meaning that the design needed to be quite rugged to avoid weird things happening when parts were demoulded.

The base design did, however, allow Atkin to implement more design considerations for different street users, reducing the risks of people tripping and making signs more detectable to pedestrians with sight-loss using long canes to navigate, this being a problem associated with metal A-frame signs.

“I’ve been really aware of the long cane trap between the feet of these things ever since I was working on the research for Sight Line, where I’d always been trying to get them to change the design,” he says.

“There’s a bit of a trade-off [with the new base], because you want to make it as flat as possible to not trip people over, but you also don’t want it so tapered that you the cane just runs over it.”

Testing times

Atkin’s designs for the injection moulded bases, created in Autodesk Fusion, were immediately successful. However, the intricacies of designing the centre posts for the blow moulding process required further iterations.

Working alongside factory engineers, Atkin updated his design to make it easier to reliably blow mould and to support volume production, in line with the expectation of producing thousands of parts each week.

Updated parts were assembled and underwent wind tunnel testing at the Building Research Establishment, before they were pilot tested for eight weeks in early 2024. These tests saw the signs set up in a high footfall area and major bus corridor and coincided with two major storms. Only one sign out of the 40 deployed was toppled by strong winds.

The contractor that managed the trial described the new design as a “game changer” and praised the ease with which signs could be quickly assembled and dismantled on large job sites.

Today, Atkins’ Highway Sign System is widely deployed across London and further afield, signalling a positive change for the better.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here