Having already transformed the humble measuring tape into a digital device engineered for modern needs, Reekon Tools set about designing a version that would help put it on more toolbelts on constructions sites around the world

In a world where almost every new product boasts a digital element for extra smartness, the humble measuring tape was slow to evolve until the arrival of Reekon Tools’ T1 Tomahawk.

The product’s design speeds up workflows and reduces the errors associated with miscalculations, misreadings and flawed mental arithmetic.

The Kickstarter launch of the T1 Tomahawk in October 2024 was a resounding success, but the sheer number of features that the product off ers means that its form factor can be off -putting to workers more accustomed to using more compact, traditional tape measures.

Enter the company’s newest model, the T1M, which directly addresses this issue. “We learned that in order to get people on board with digital, we needed to compactify, simplify and lower the barrier to entry,” says Reekon CEO Bart Saminski.

While the goals set for the T1M were clear, the industrial design team at Reekon’s headquarters in Boston, Massachusetts knew that it would still need to replicate its big brother’s rugged character.

“We wanted to make a tool that someone could pick up and feel like it belongs in the field and can get beat up without any consequences,” says Saminski.

The design team resolved to get into the mindset of a construction worker who has never used a digital tape measure. How might they feel seeing the product and how would they react to certain features existing or missing?

Deciding on which features to keep not only had engineering and architectural implications, but also repercussions for form factor and interaction, making it a critical early hurdle in the design process for the T1M.

Rich in features

The team resolved to repeat key features from the original model in the T1M, such as the digital read-out off ering 0.5mm accuracy, the digital screen and the Bluetooth connectivity that means that measurements can be saved to a mobile phone app, so workers aren’t having to write anything down.

Equally, the team also wanted to keep valuable functions such as centre-finding, as well as the ability to measure from the back of the device and to take relative/zero measurements without having to do any mental arithmetic.

Some sacrifices would need to be made. However, members of the design team were adamant that even with reductions from the T1 Tomahawk’s features, the T1M workfl ow still had to be faster and more accurate than what could be achieved with any traditional tape measure.

To soften the impact of losses, they developed some clever new solutions. To replace the T1 Tomahawk’s laser alignment function, for example, a marking square was developed that attaches to the mouthpiece of the device, letting users make precise and square markings.

Once the feature set was locked in place, the team started to develop the exterior design language for the T1M.

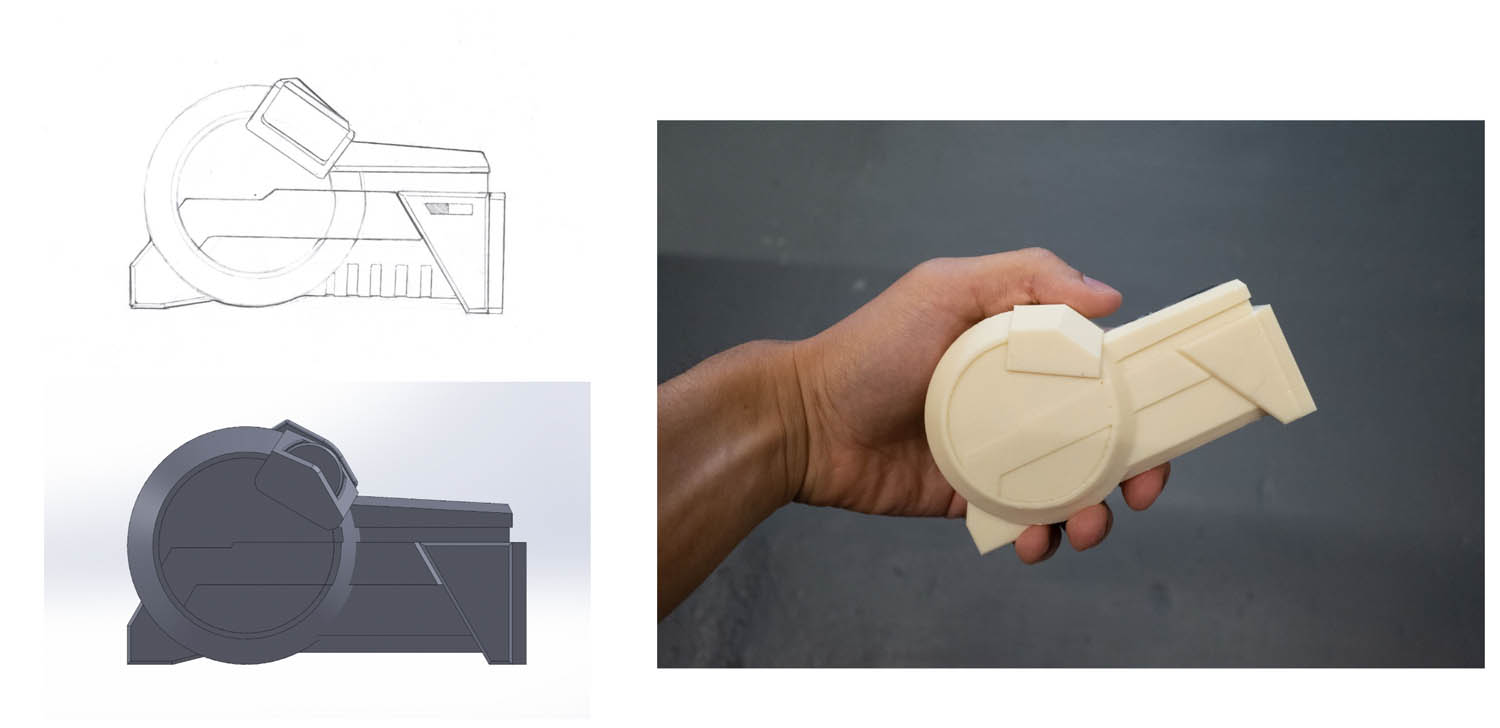

In early sketches and prototypes, the team explored various form factors and ergonomics, taking great pains to understand how the device would be held, how its buttons would be reached, and the visual impact of the device. They then shifted focus to developing the necessary electronics.

The team worked with two 3D CAD software packages to develop their design: Autodesk Fusion and Dassault Systèmes Solidworks. This was to accommodate the personal preferences of individual designers in the team and, in the case of Fusion, the ability to run on Apple Macs. In their experience, working with Fusion was quicker for fast iteration modelling compared with loading the full product assembly in Solidworks.

Hand tools

Unsurprisingly for such a tactile product, it was physical prototyping that proved the driving force for the T1M’s design. Early foam models were carved and existing products hacked by shaping clay over the top to fi nd the best fit.

“As the design evolved, we began physically prototyping all the features we wanted to include. From the marking square to the auto lock button, everything went to hundreds of iterations before arriving to its final form and most, if not all of it, was done with physical prototyping and hands-on testing,” explains Saminski. “You can’t truly understand how something will function and feel until you have a physical model in your hands to test.”

As forms took more detail in CAD, the prototyping process shifted to 3D printing. Initially, this involved producing fast FDM iterations using the team’s Bambu Lab X1 before the team moved to using the higher fidelity Formlabs Form 4 to test small tolerances, build moulds for urethane casts and to make final models used to appraise material fi nishes and edge treatments.

Throughout the physical prototyping stages, Reekon conducted hands-on user tests to see how users would react to certain changes in layout, grip and product features. Without physical prototyping, the company would never have arrived at the product it off ers today, says Saminski.

The final 20% of the process saw the team refining edges, choosing colours and ensuring brand consistency, in a process of fine-tuning that Saminski says took almost as long as the first 80%.

“Every detail was designed to ensure the T1M not only works flawlessly but also feels and looks like it belongs on the tool belt,” he says.

With the requisite looks and precision all compactly packaged for demanding professionals, the design of the T1M has been, by any measure, a resounding success.