New Designers gives us the chance to assess the latest crop of graduate design talent all under one roof, and this year didn’t disappoint.

Click through to see our first selection of highlights, the second part follows on tomorrow, with our top five picks getting their own individual blog post later in the week.

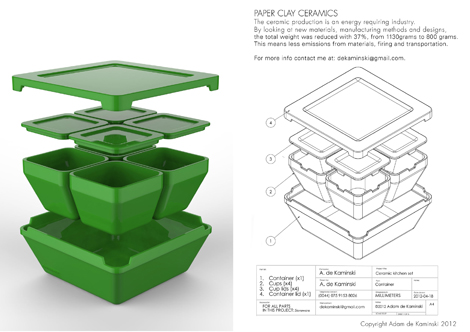

Adam De Kaminski – Falmouth

Falmouth University had probably the smallest exhibiting space of New Designers 2012 with one of the largest exhibiting groups.

To get around the problem Swedish student Adam de Kaminski created an interactive, big screen, augmented reality plinth working via personal pictograms to show off the class’ works.

Adam has some great ideas that spanned almost every design area, from an architectural cycle-hub, to his in depth look at the manufacturing practices of ceramics, and the huge amounts of waste involved. Instead he researched and arrived at his own 3D-printed solution using a paper-based ceramic – a substantially greener material with a wider range of build styles.

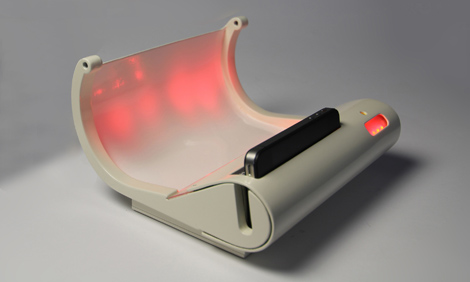

Alasdair Gauld – Duncan of Jordanstone, Dundee

Although most people are aware of their energy consumption at home (they’re paying for it), it’s not often clear how much waste you’re producing at your office desk.

Alasdair Gauld’s Thinking-Watt switches on a desk-user’s power with the insertion of their mobile phone (always with its user) turning everything off again once removed, but contains a coloured light indicating just how much juice is being used. Not only does this affect the user, but others around can see, and the boss can even receive a weekly stat sheet of everyone’s use. (No more plugging in a microwave under your desk).

Very much a hands-on designer, prototypes were built from card first for evaluation before being modelled in SolidWorks. The final build was done in MDF with a tricky bit of plywood bending to achieve the curved display.

Andrew Williams – Central Saint Martins

Taskbot is a desktop companion that helps a person working from home focus on their work, challenging them to develop self-control through ‘gamification’ training.

Andrew’s tool helps with issues of work/life balance to make the user aware of where their time goes, and using the ‘pomodoro technique’ to get them to work in short bursts. It’s also a rather cute desk companion, glowing red, jumping and buzzing with anger should you find yourself browsing Twitter for too long.

After copious sketching and foam modelling he used Rhino to design the chassis along with the ‘limbs’, laser cutting them from white acrylic and using a heat gun to help shape them.

Arif Suzaili – Sheffield Hallam

For fans of fancy salads, and more relevantly, interesting kitchenwares, Arif has designed a range of products that caught the eye – including his Kiwi vinegar/oil dispenser.

Best of all is his Mangtin tiffin set – taking the well known south-east Asian concept and redesigning it for western lunchtimes.

Having spent time considering the right materials, shapes and function, Arif sketches out ideas in Coral Draw, before modelling his designs in SolidWorks.

Benjamin Ambrose – Huddersfield

Benjamin had some great, practical designs with some great simple touches and an eye on the manufacturing process, rather than simply elaborate aesthetics.

His lunchbox design was inspired by the unhealthy practice of eating lunch over a keyboard, and has ample built-in compartments. Meanwhile his ‘Chairer’ looks typical of a piece of furniture suited for student halls, part sturdy lounge chair, part clothes dryer.

Designed in SolidWorks, everything was considered for moulding and manufacturing processes for mass production.

Benjamin Jones – Staffordshire

Working on the cusp of new technologies, Benjamin had two impressive designs for future products – the Cocoon rucksack for the emerging market of backpackers that stay in luxurious resorts, but need to rough it while making their way there; and the Mevo toy, essentially a monkey that gains weight.

The cocoon benefits from optimised weight distribution, and enclosed day bag, fin-ray straps to ease the weight, and a rising compartment that, should it all get too much, you can transform into a sleeping pod.

Mevo is a smart toy, the less you play with him the fatter he gets as a hydrogel is released into his expandable parts while placed on his stand; the more you play with him the cleverer and more agile he gets – like a physical Tamagotchi.

Byron Goodsir – Bournemouth

When swimming you’re less aware of the environment around you, making it difficult judge performance, Byron addressed this problem with the Swim Hare – a visual marker for the swimmer that provides real-time feedback.

The flexible LED lighting runs along the centre of the lane at the bottom of the swimming pool, effectively giving you something to chase, which can be programmed to whatever time you are aiming for.

The housing system was designed in SolidWorks, with prototypes being built from blue foam for tests, before the finished prototype was built, with some parts 3D printed from the CAD model.

Callum Fisher – Robert Gordon University, Aberdeen

Tackling portion sizes before any cooking begins is a simple way to ensure we don’t all become monstrously obese, and cut down on any waste left behind – Callum’s bright and simple product range is a quick, simple to use way around this.

A simple acrylic mould was used to create the silicone discs and details for the MyMeasure scoops, which when bent into a cone makes it simple to measure rice, porridge and pasta, while laying flat when stored in a kitchen drawer.

The FatMan bowl, with it’s internal figure getting more rotund the bigger your portion, was surface designed in Rhino, before a mould was milled and the bowl vacuum-formed. The overall designs were highlighted by some nice renderings done in Cinema4D and Vray.

Daniel Humphreys – Plymouth

With some classic 1950s americana styling cues, the Thunderbird speedboat is an eco-driven beauty, with a foldable rear deck/canopy.

A winning concept design at the ‘Abitare La Barca’ boat show, Daniel then had to take his sketches into 3D, morphing from Adobe Photoshop, into Solidworks, and later Modo to render a finished image.

The project isn’t as fanciful as it might first appear – with the roof down, the boat space increases by 40 per cent; with it up, it becomes faster on the water and easier to dock.

{encode=”danielhumphreysdesign@googlemail.com” title=”danielhumphreysdesign@googlemail.com”}

Emma Doran – UWE, Bristol

Emma’s Co-See cot is designed to accommodate for the needs of both the mother and infant during the first six months of the baby’s life.

A bedside design it has an adjustable base that can be inclined to alleviate reflux and sickness; and side options that allow ease of access and eye contact while the mother’s in a separate sleeping space.

Emma somehow managed to incorporate all of the safety standards that usually limit design possibilities, creating an aesthetic piece of furniture. From sketches the product was modelled in SolidWorks before using V-Ray to render.

Glenn Kitchener – UCLAN, Preston

In the developing world there are some jobs that you’d rather not think about, such as the cleaning of the toilets where the contents have to be taken away by hand (no sewers) and the buckets cleaned.

The cleaner of said buckets will be glad to hear that Glenn’s simply mechanised bucket cleaner has been designed as part of a brief from Unilever. Built on readily available parts, the jet wash cleans the inside of the buckets, which are attached by an already present screw top.

From start to finish several sketches, models and even a working test ring were designed to prove the theory, using a mixture of Autodesk Sketchbook and SolidWorks to design the CAD model.