Mirror is one of the hottest home fitness brands on the market, so finding a suitable design aesthetic for its accessories line really put Leadoff Studio through its paces, as Stephen Holmes reports

When athletic apparel brand Lululemon branched out into hardware, its goal was to create a product that, when switched on, transforms a living space into a fitness studio, and when switched off, simply looks like a stylish, full-length mirror.

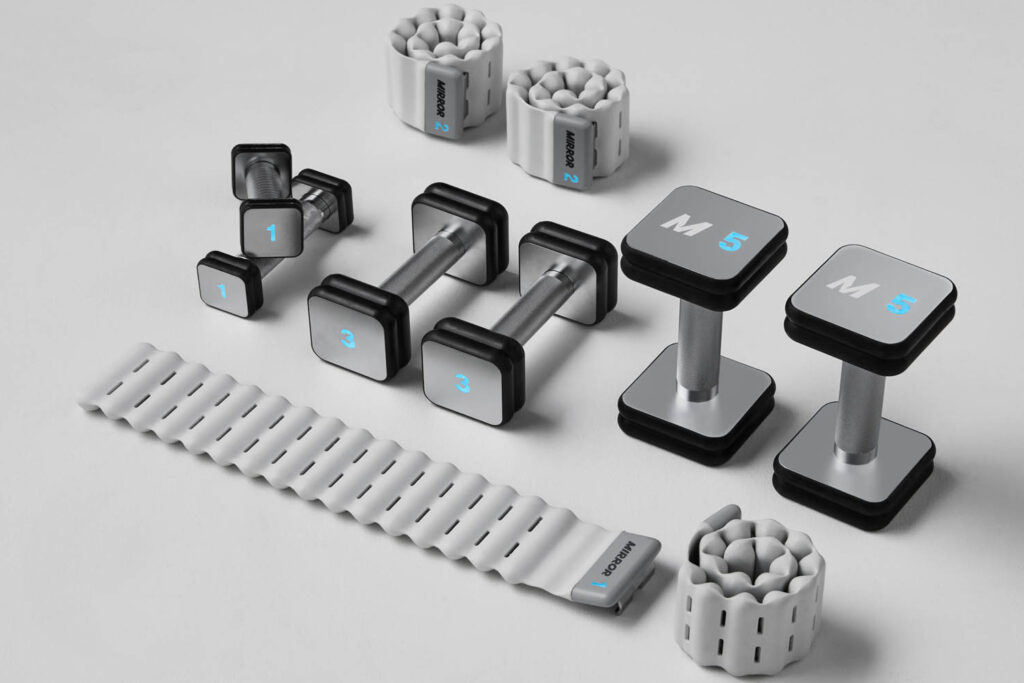

A big hit during the pandemic, when gym memberships were jettisoned and fitness became an at-home operation, the next, post-pandemic step for Mirror was an extension of the scope of workouts offered, as well as the launch of an accessories range.

“Before we began this design project, Mirror’s only physical product to date was the Mirror itself,” says Jordan Diatlo, CEO of Leadoff Studio, which was brought in to develop the product range.

“The whole purpose of the product is to blend in with your home when it is not in use as a fitness device, and simply function as a mirror. The conceptual thinking behind the Smart Weights and Ankle Weights was to take Mirror’s brand off of the wall and into the room, or onto the user’s body.”

However, with new competitors flocking to the fast growing home workout equipment market, Leadoff knew it would be critical to the product’s success that it could stand out from the competition in terms of functionality and visual identity.

The technology and user experience of these products is unique, explains Diatlo from Leadoff’s West Manhattan headquarters, home to its team of four designers. The devices sync with the Mirror, enabling users to count exact reps and easily track their progress over time. By pairing devices with the Mirror, the app provides advanced performance metrics beyond anything else on the market.

Mirror’s Smart Weights are designed specifically to function with the breadth of Lululemon’s workout programmes. A square end cap face was implemented, to allow users to switch between ground exercises or standing exercises while using the same weights, while differentiating the product from other hexagonal or circular dumbbells.

The Ankle Weights take this thinking even further, with the ability to flex in any direction. Even the weights within the product are flexible.

Different directions

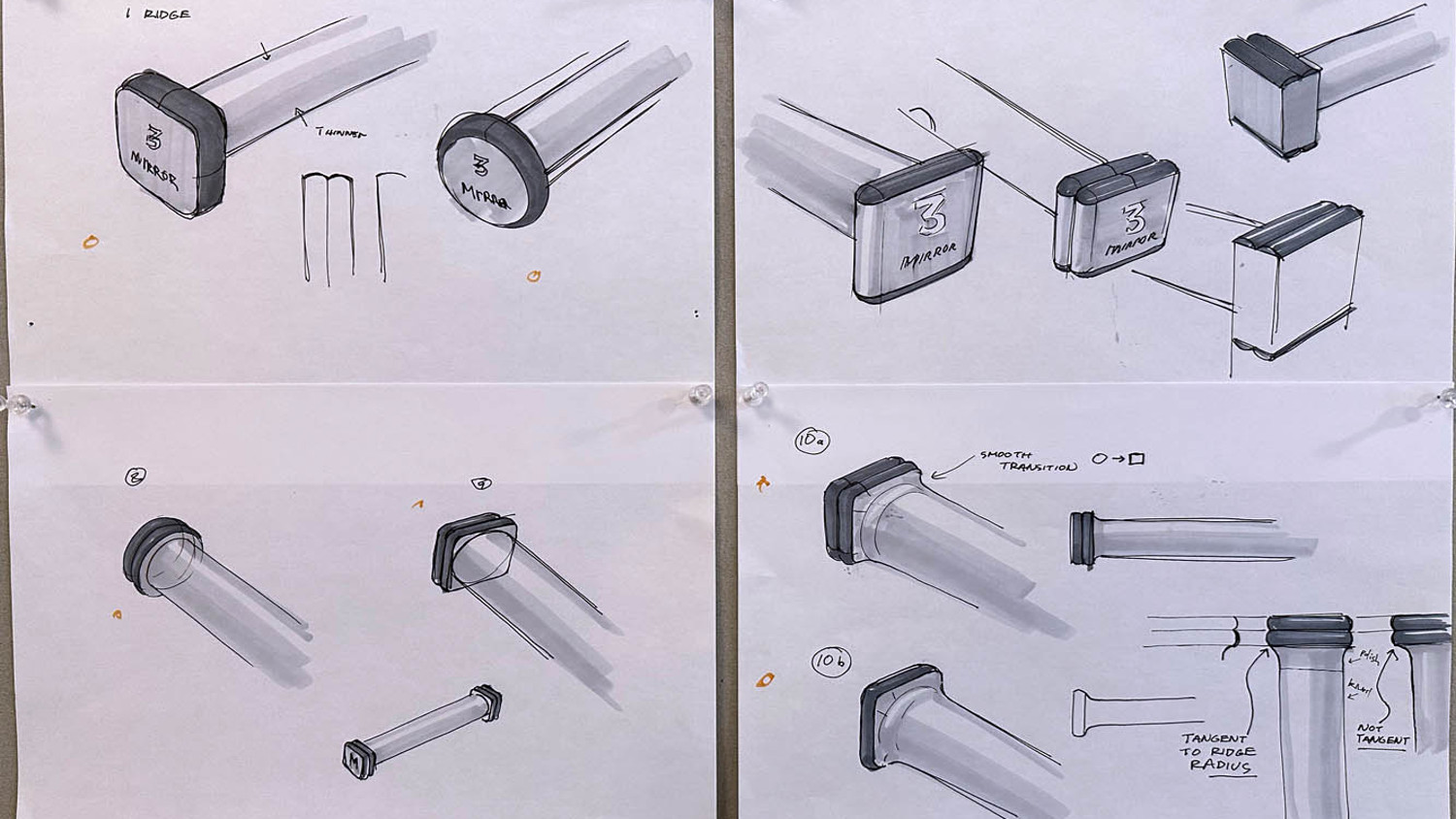

Design work began with sketching, but quickly moved into Solidworks. “In our conceptual stage, we showed Mirror a range of concepts that fit the Lululemon brand, but began to pull it in different directions. Since this is the company’s first off-the-wall product, it would begin to define the physical brand language of this service,” says Diatlo.

“We showed Mirror varying concepts in the beginning, and they liked one which became the design direction for the project. Through collaboration with their engineers, we eventually got to a solution that made the aesthetic functional, but it was a difficult task.”

With a direction selected, the design team honed every last detail to ensure the products would feel like premium technology without being intimidating.

Through prototyping and rendering, the designs evolved, while close collaboration with Mirror’s engineers ensured the right proportions stayed intact as the team focused on the external design and user interaction.

Details are hyper-critical, since they add up to give one a subconscious feeling of what the product is and what the brand stands for

“Mirror was hyper-aware of the aesthetics from the start, so we spent a ton of time in Keyshot, rendering out options for every minute detail and showing a variety of CMF options,” says Diatlo.

“These details are hyper-critical since they add up to give one a subconscious feeling of what the product is and what the brand stands for. Mirror provides users with the highest quality and the details have to speak to that. There was a lot of Keyshot rendering to visualise this along the way.”

Universal design

As the project progressed, the team had to figure out how to make the design universal, where one size fits all wrists and ankles, within one product. To do this, it created a product that intentionally overlaps as you wrap it. The clasp that holds it in place, along with the correct spacing of the weights and rigidity of the material took extra patience and fine-tuning to get right.

An early prototype used rigid metal bars for the weights, yet proved uncomfortable for users. A completely flexible weight was invented, prototyped and manufactured, in order to give the ankle weight full flexibility and conformity to the user’s body.

“Even with all of the embedded tech, I think this is one of the most innovative functions of the device,” says Diatlo. “It’s a true testament to the collaboration between design, engineering and manufacturing on this project.”

For the handheld Smart Weights, quick prototypes made of dowel rods and foam were used to mock up the shapes. While carrying no weight, they allowed the team to understand the proportions of weights and how they sat together as a line of products.

Eventually, FDM 3D printing was used to produce prototypes – including segments of the ankle weights and some smaller UX details, like battery access on the different weights.

From there, higher fidelity prototypes were outsourced, in order to test the weight and the materiality of the products, allowing the team and client to get a feel for the function and identify where to fine-tune the products.

Numerous studies were done to get the colours of the Ankle Weights the perfect shade of cool grey, helped by Keyshot to not only get the right look, but to simulate elements like the backlit numbers on the smart weights when both on and off, and how that changed the feel of the product. The result: a cool, stylish accessories range, to match the original Mirror.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here