With textile textures, patterns and colours taking a more prominent role in product design workflows, Gabrielle Brown attended Epson’s Textile Academy to witness the next generation of designers get hands-on with the latest printer technologies

From headphones to car interiors, textiles play a much bigger role these days in product design. That leaves many designers in need of a printer that can handle vibrant colours with accuracy, speed and repeatability, as well as help them meet demand for customisation.

So how can designers best incorporate customised fabrics and designs throughout the process from prototype to finished product?

Printer company Epson claims to have answers. In late November 2025, it held its second Textile Academy event, which offered young designers the chance to engage and experiment with textile printing. On this occasion, undergraduates from Nottingham Trent University and Loughborough University were invited to try out Epson’s textile printers for themselves and get some hands-on, workshop-based education on the subject.

Epson’s SureColor F2200 may look like a pretty average printer and offers a compact design that makes it small enough to slot neatly into any workshop. But in fact, it’s a direct-to-garment (DTG) printer that has been developed for businesses that need to produce sometimes complex designs on a variety of garments.

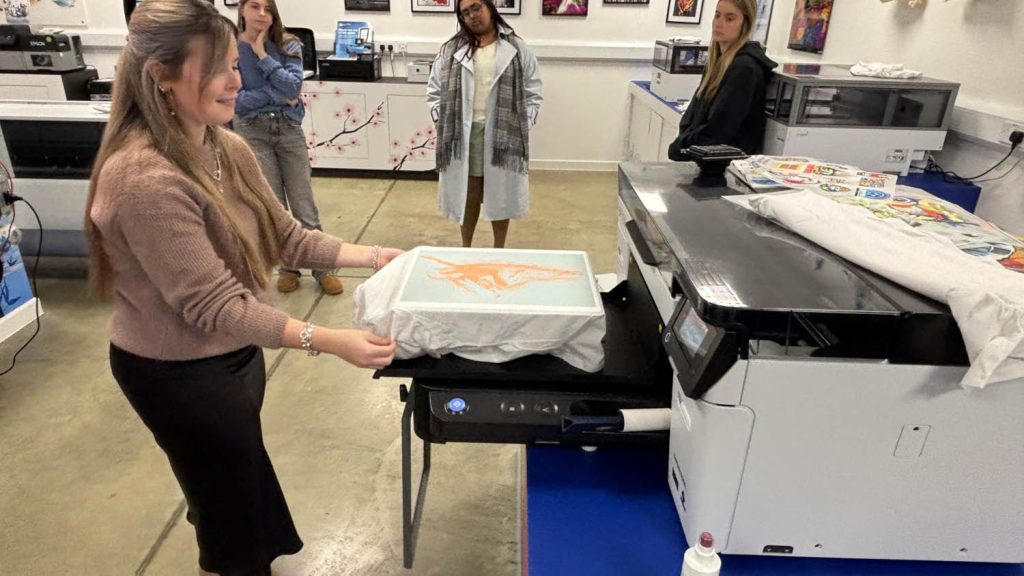

The SureColor F2200 works by jetting water-based textile inks directly onto a pre-treated garment using a specialised inkjet printer. The fabric is laid flat on a platen, a white underbase is added if needed, and microscopic droplets build up a full-colour design. The print is then heat-cured, so that the inks bond with the fibres.

More vibrant textiles

The students at Epson’s Textile Academy event were taught how to use the DTG printer and were soon able to print their own designs onto T-shirts.

“We’re obsessed with the idea of repeatability, so that if you did a print for a customer today and they came back in six months’ time, the two prints side-by-side would be identical. All of that is very challenging for a manufacturer to design and engineer for a mass market” says Epson head of sales, Phil McMullin, adding: “We discovered fairly quickly that the crown jewel in our technology is the piezo print heads.”

Epson’s PrecisionCore printheads use ultra-thin piezoelectric actuators and densely arranged nozzles to fire extremely precise, consistent droplets. This allows for accurate colour placement, smooth gradients and reliable performance with textile inks.

The SureColor G6000 direct-to-film (DTF) printer can add super vibrant and durable prints onto a range of fabrics. For example, it can add tactile logos to T-shirts, or team numbers to sports jerseys, or in this case, a student’s own design onto the back of a hoodie.

The picture or pattern is first printed onto transfer film using ink and a white base if necessary. Once the ink is applied, a layer of hot-melt adhesive powder is added to the wet print. The film is cured and then pressed under heat onto the hoodie. When the film is peeled away, the student’s artwork is revealed.

“We are usually only exposed to dye sublimation printing, so it’s been great to learn how direct-togarment and direct-to-film printing techniques can be utilised” says Ashley Hancox, a textiles student at Loughborough University.

Epson also makes dye sublimation printers for designers who need to print onto hard as well as soft goods. These work by printing a design onto sublimation transfer paper using dye-sublimation inks. Then, using a heat press, the dye on the paper transitions into a gas while the fabric is temporarily opened to absorb the dye. As it cools, the dye re-solidifies inside the fibres, embedding the image into the material.

Epson’s Textile University event showed how textile printers have evolved, allowing designers to bring them in-house much like a standard paper printer. It’s quick and easy to whip up designs and prototype products right there in the workshop, testing fabrics, colours and placement. Designers can experiment with personalisation, offering more options to customers without lengthy order times and high shipping costs.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here